Method foe straightening pendulous railhead on site and hydraulic pressure railhead straightener thereof

A technology of on-site calibrating and calibrating machine, which is applied in 6] The present invention adopts the following technical scheme: the on-site field of drooping rail heads can solve problems affecting production, low work efficiency, and poor safety, and achieve portability, high work efficiency, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

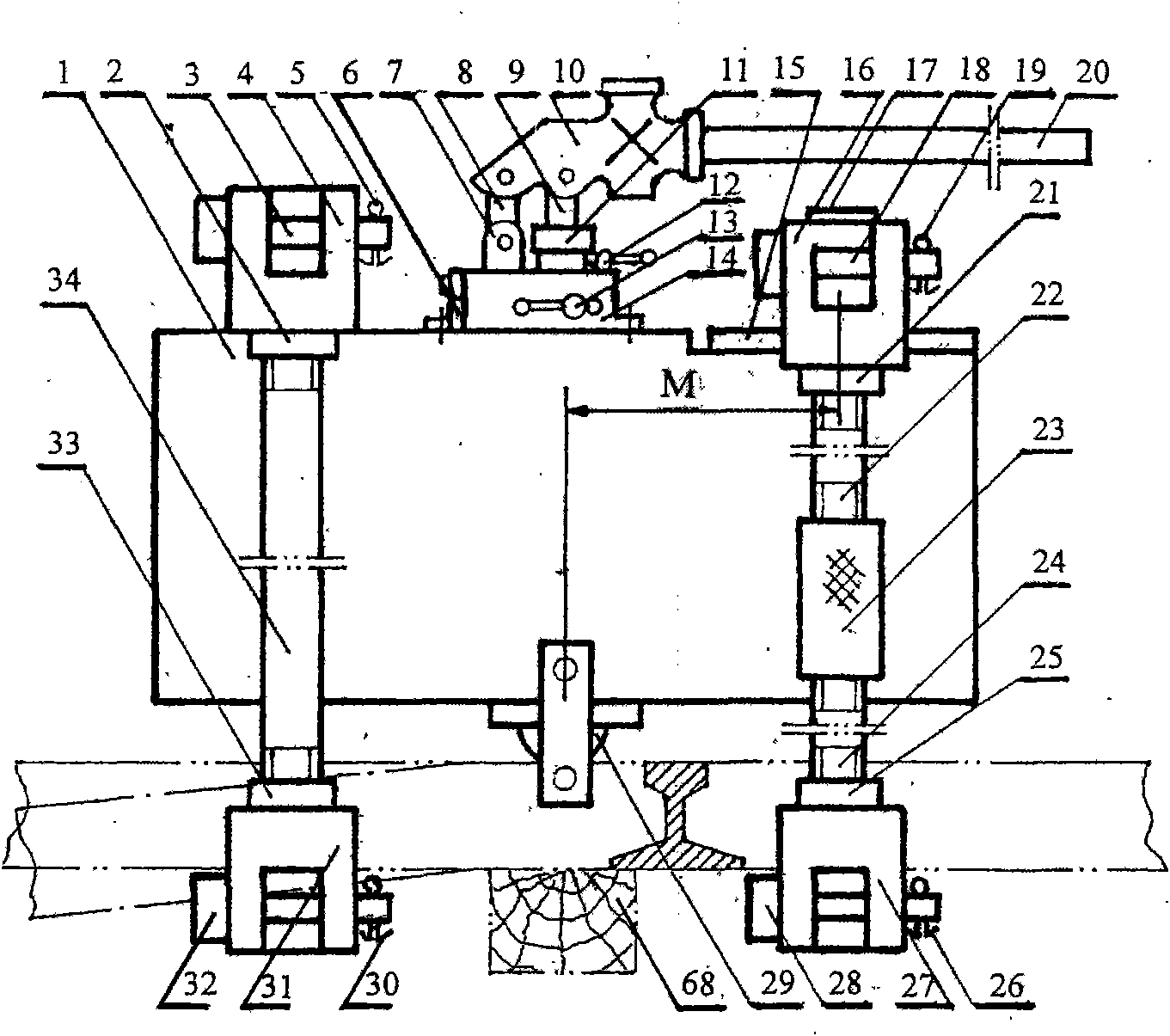

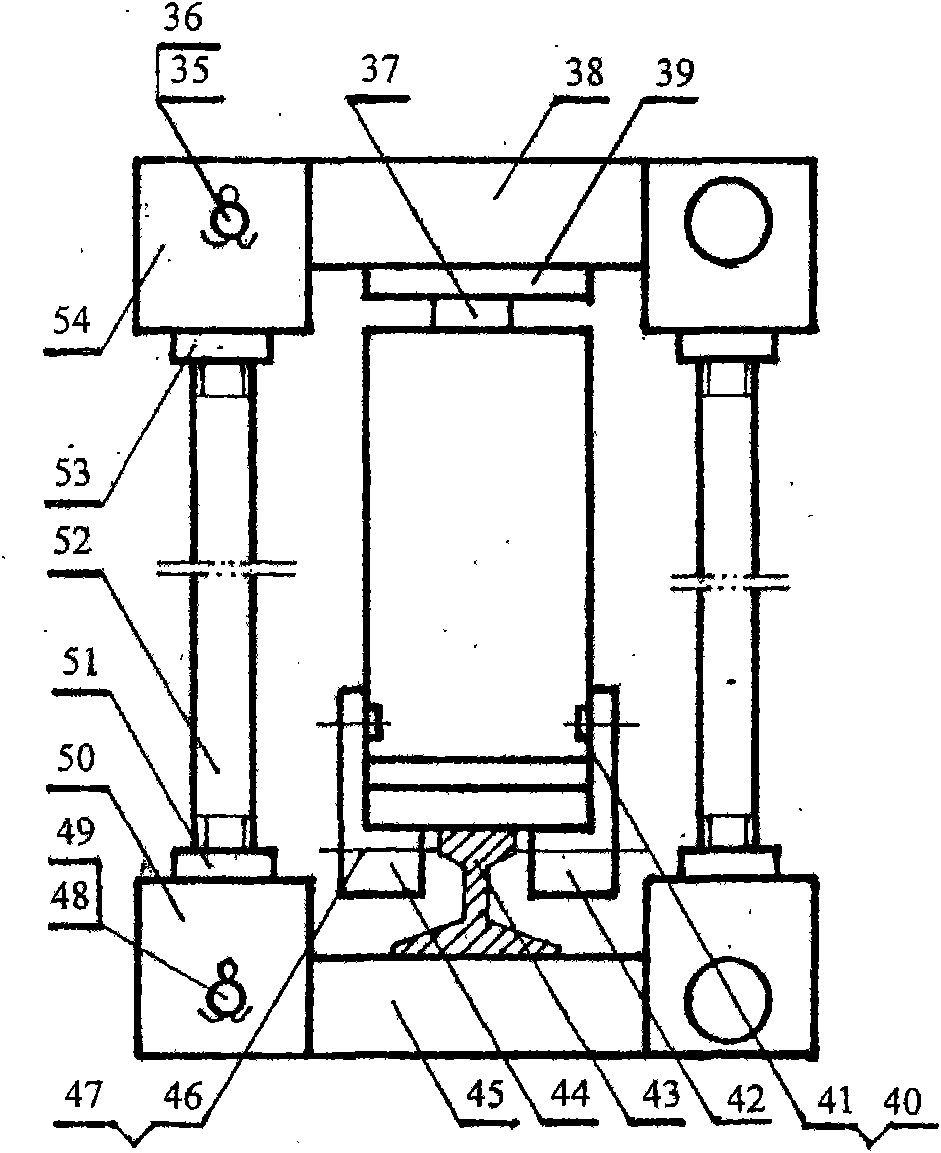

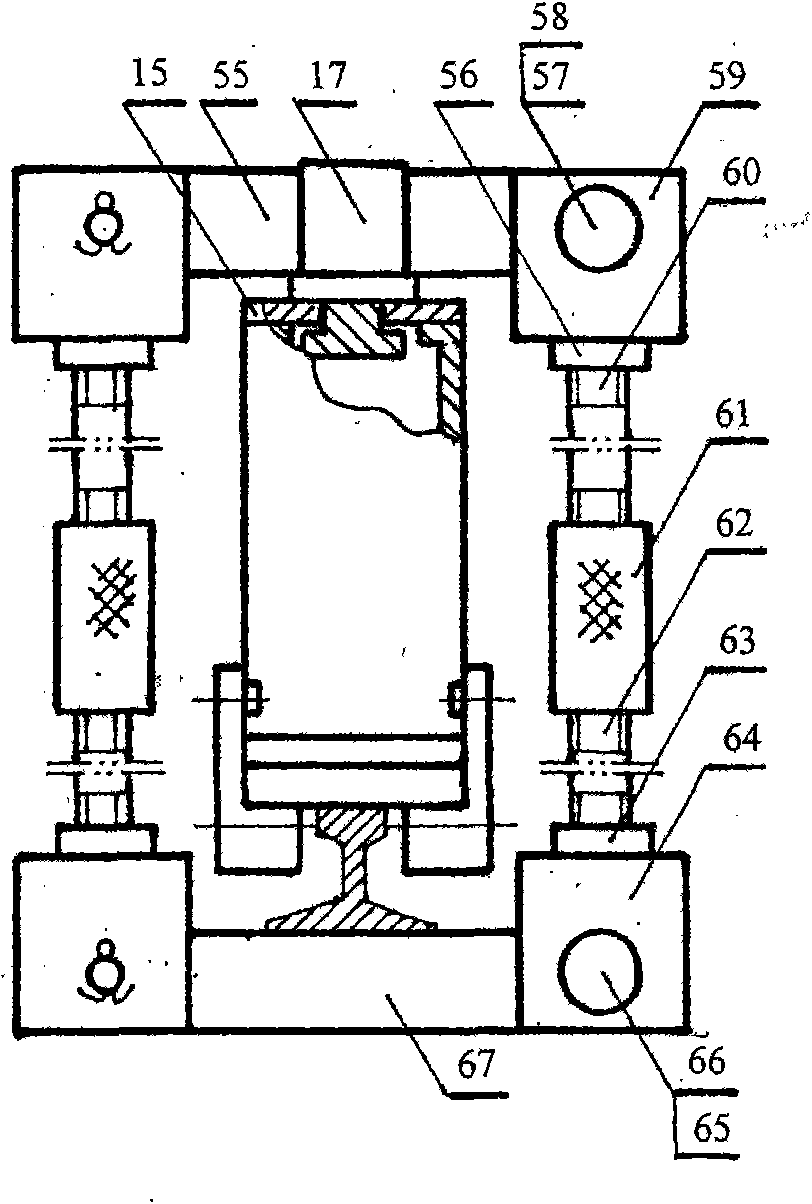

[0023] according to figure 1 , figure 2 , image 3 As shown, the fuselage 1 is placed on the rail head working surface where the deformed rail 43 needs to be straightened, the supporting jack assembly 29 is placed on the deformed bend, and the positioning bolts 46 and 47 are tightened, so that the fuselage 1 is fixed on the rail 43 Top; install the main and auxiliary platen frame components on the fuselage 1 respectively, adjust the fulcrum distance M according to the position of the crossties 68, that is, adjust the ring groove of the follower shaft of the follower positioning cover assembly 17 and the hole chute of the moving pad Relative position; respectively take out each cotter pin and each garden column pin of one end of auxiliary pressing plate 45 and 67, after the main and auxiliary pressing plate frame assemblies are opened, the auxiliary pressing plate 45 and 67 are respectively inserted from below the rail and put in place, Install the garden column pin and cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com