Image-based method for detecting qualified property of dimension of railhead cross-section contour

A technology of contour size and detection method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of inconvenient quantification results, low degree of detection automation, inconvenient operation, etc., and achieves high degree of automation, convenient operation, and improved The effect of edge positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

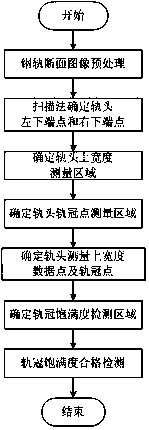

[0040] The present invention adopts such as figure 1 The image-based qualified detection method of the rail head section is shown to realize the measurement of the fullness of the rail crown in the geometric dimension of the rail image. The specific implementation steps are as follows:

[0041] 1. Rail section image preprocessing, specifically including the following steps:

[0042] (1.1) Carry out median filtering to the collected target image to reduce noise interference;

[0043] (1.2) Use the maximum between-class variance method to perform threshold segmentation on the filtered image to obtain the binary image of the track head.

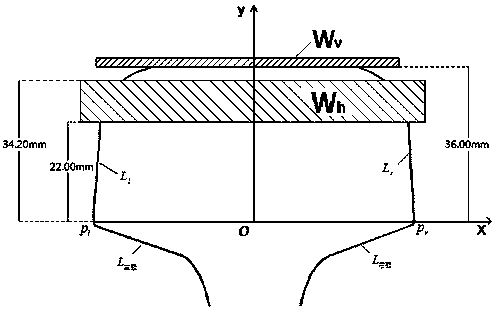

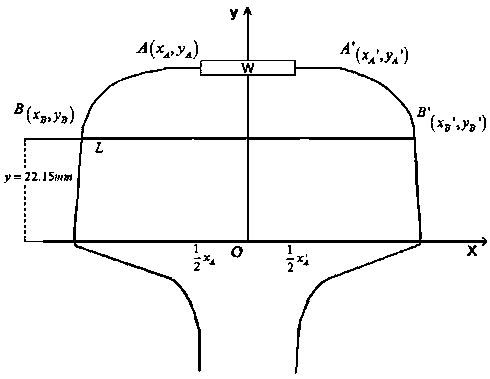

[0044] 2. The scanning method determines the lower left end point and the lower right end point of the track head, which specifically includes the following steps:

[0045] (2.1) For the binary image of the rail head obtained in the first step, use the scanning method. First, start from the upper left corner of the image, scan from left to rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com