Switch rail polishing device for rail maintenance vehicle

A technology for maintaining vehicles and point rails, which is applied in the direction of grinding drive devices, grinding machines, and parts of grinding machine tools. It can solve the problems of unstable grinding quality and low grinding efficiency, achieve wide application range, improve support effect, The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

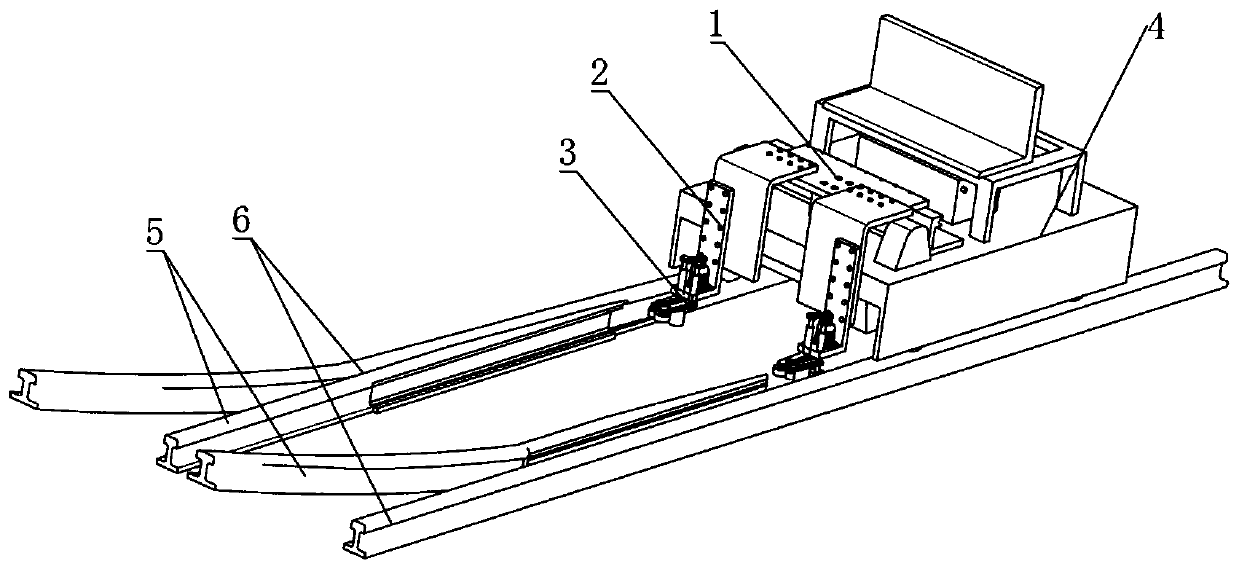

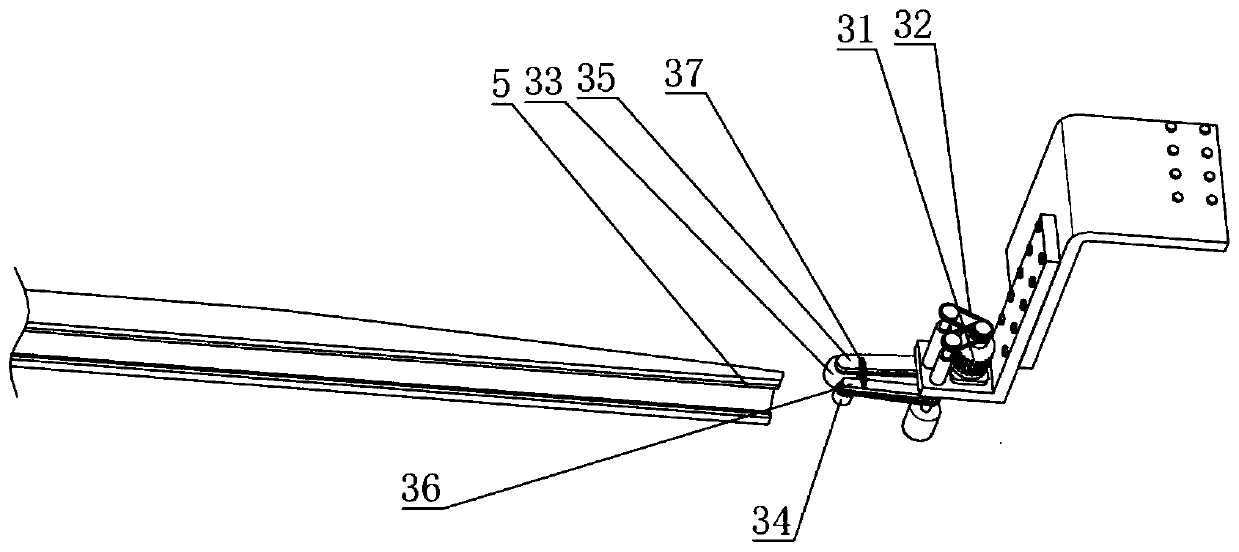

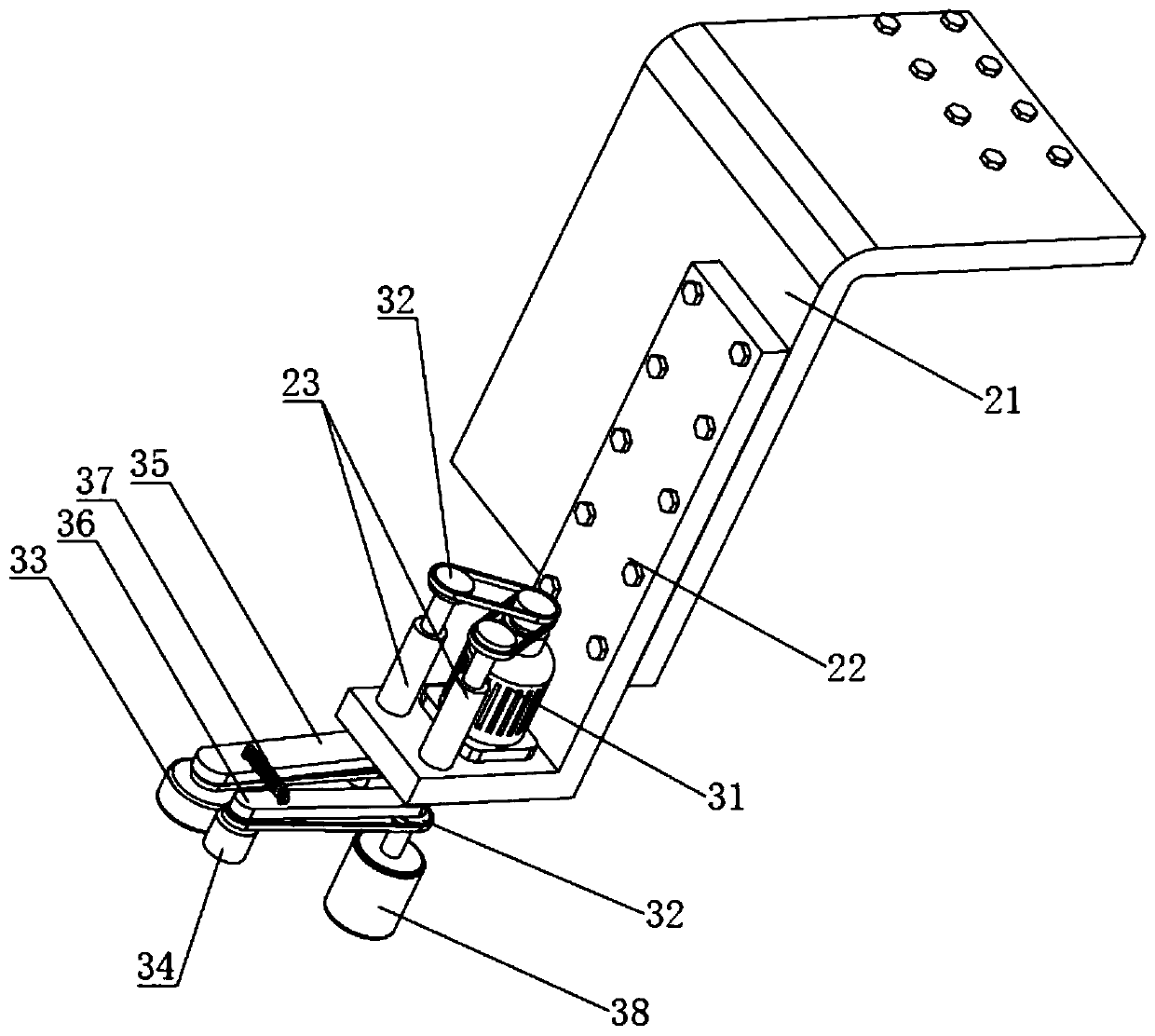

[0027] Such as Figure 1-6 As shown, the present invention provides a sharp rail grinding device for a track maintenance vehicle, which includes a lateral movement mechanism 1, a mounting structure 2 and a grinding mechanism 3, and the left and right ends of the sliding plate 11 of the lateral movement mechanism 1 The installation structure 2 is fixedly installed, and the grinding mechanism 3 is installed on each of the installation structures 2. The grinding mechanism 3 includes a driving motor 31, a rail waist grinding wheel 38, a rail head outer grinding wheel 34, and a rail head inner grinding wheel. Grinding wheel 33, belt drive mechanism 32, rotating arm one 36, rotating arm two 35 and extension spring 37, two belt pulley shafts 39 are installed in rotation on the described installation structure 2, two described belt pulley shafts 39 are arranged side by side and both The upper ends are all connected to the output shaft of the drive motor 31 by a belt transmission mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com