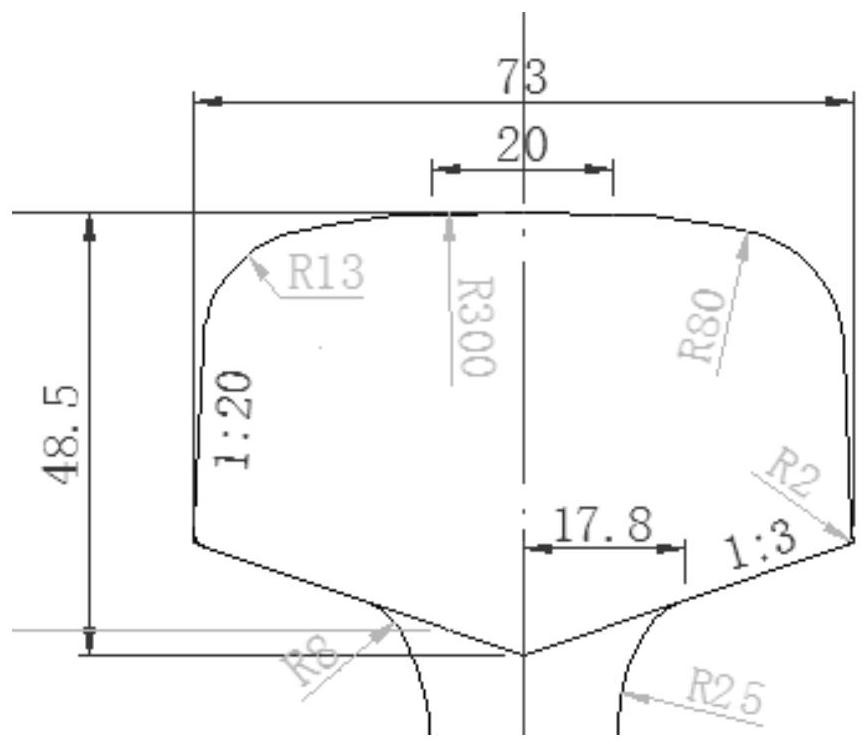

Novel railhead profile steel rail and production method thereof

A technology of rail and rail head, which is applied to the 60N new rail head profile rail and its production field, can solve the problems of affecting the service life, fatigue nuclear damage, wheel and rail wear, etc., and achieve the effect of prolonging the service life and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: New Rail Head Profile Rail

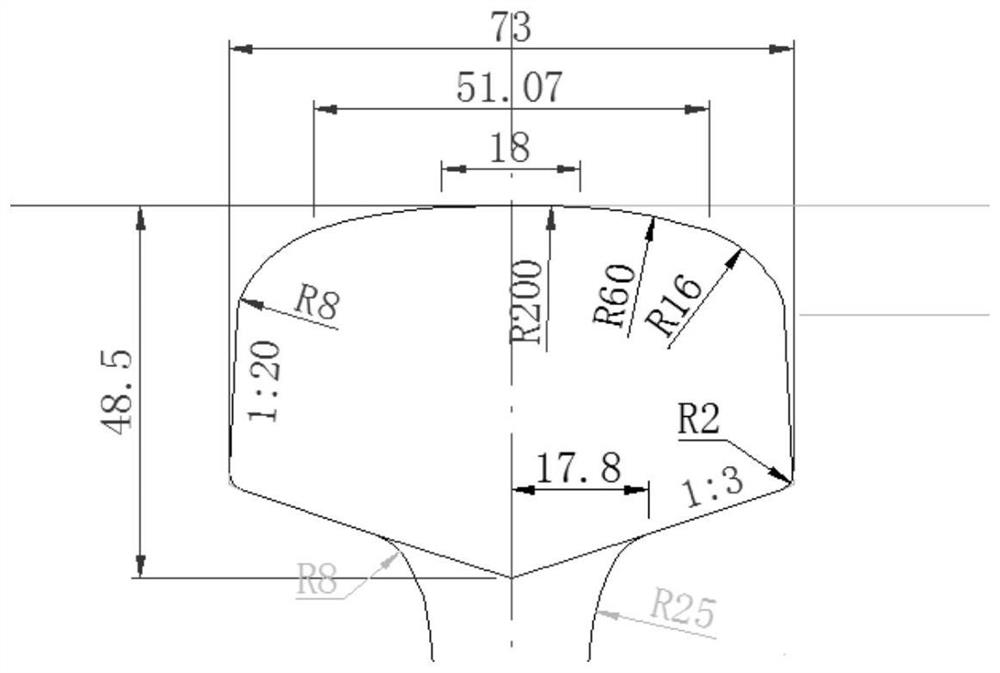

[0018] Such as image 3 As shown, the schematic diagram of the cross-sectional structure of the new rail head profile rail (60N rail) provided by the present invention is shown, which can be based on the base of the 60N rail, and the difference is that the top profile has seven arcs, The radius of the middle arc is 200 mm, and the radii of the arcs from the middle to both sides are 60 mm, 16 mm, and 8 mm, respectively. The width of the top profile is still 73mm, but the width of the middle arc is reduced to 18mm, and the two arcs with a radius of 60mm and a radius of 16mm meet at the junction of two arcs with a radius of 60mm and a radius of 16mm on the other side The distance between the junctions is 51.07mm. The new rail head profile rail provided in this embodiment is designed based on the traditional 60 rail, and the rail head profile is redesigned according to the wheel profile, which can implement wheel-rail profile matchi...

Embodiment 2

[0019] Embodiment 2: the production method of new rail head profile rail

[0020] The molten iron composition that the new rail head profile steel rail that the present invention adopts is identical with the molten iron composition that produces 60 rails in the prior art, for example can adopt U75V rail steel, and concrete production process comprises the following steps:

[0021] 1) Pretreatment of molten iron: the fluctuation range of P content in the molten iron composition is 0.146% to 0.148%, the S content is 0.051%, and the fluctuation range of P and S content is small, which can meet the smelting requirements.

[0022] 2) Converter smelting: medium-carbon drawn steel is used at the end of the converter, the carbon content of the steel tapped from the converter ranges from 0.08% to 0.11%, and the P content of the tapped steel ranges from 0.009% to 0.013%.

[0023] 3) LF furnace refining: According to production requirements, LF uses medium alkalinity and strong reducing ...

example 1

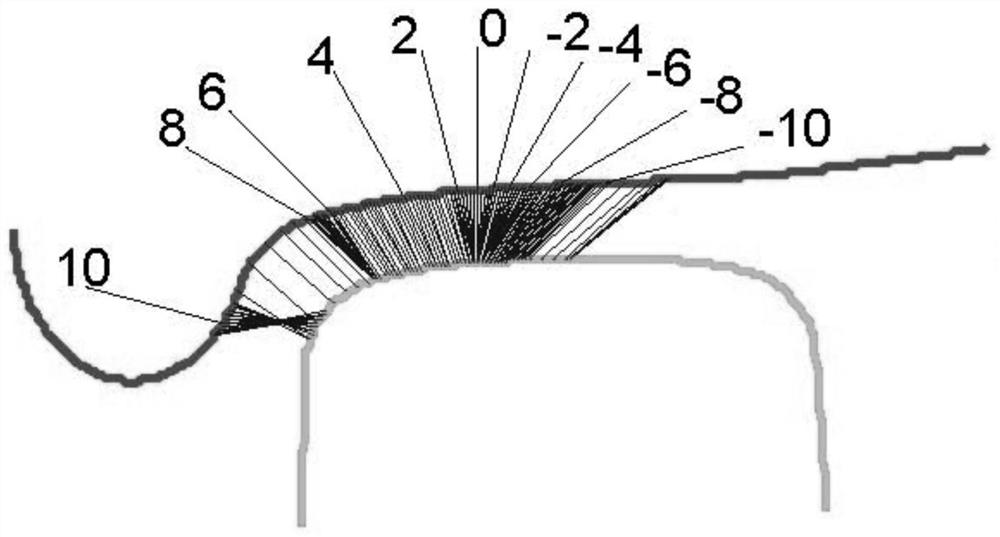

[0052]This example adopts the new rail head profile steel rail that above-mentioned embodiment 2 obtains to carry out wheel-rail contact point simulation calculation and analysis (curve diameter 600m), the result is as follows Figure 4 As shown, it can be seen that when the curve radius of the newly designed profile rail 60N rail of the present invention is 600m, the contact point of the 60N upper strand rail is obviously centered. Compared with the 60N rail, under the curve conditions of R600m and H70mm, the maximum contact stress of the 60N upper strand rail 21% reduction and 9% reduction in Mises stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com