Steel rail integral air blast quenching experimental device

An experimental device and rail technology, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problem of inability to verify the relationship between the air-cooled deformation law and mechanical properties of the rail bottom, the lack of theoretical basis for the quenching process parameters of the air-cooled quenching device, and the accuracy of experimental data Sexual impact and other issues, to achieve the effect of compact structure, ensuring accuracy and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

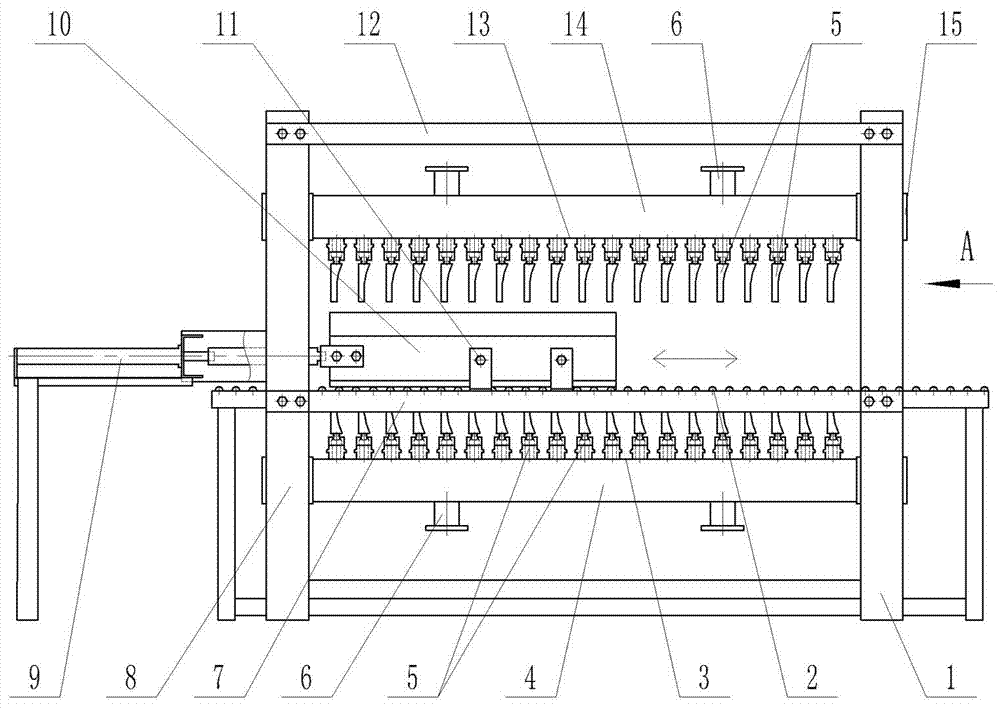

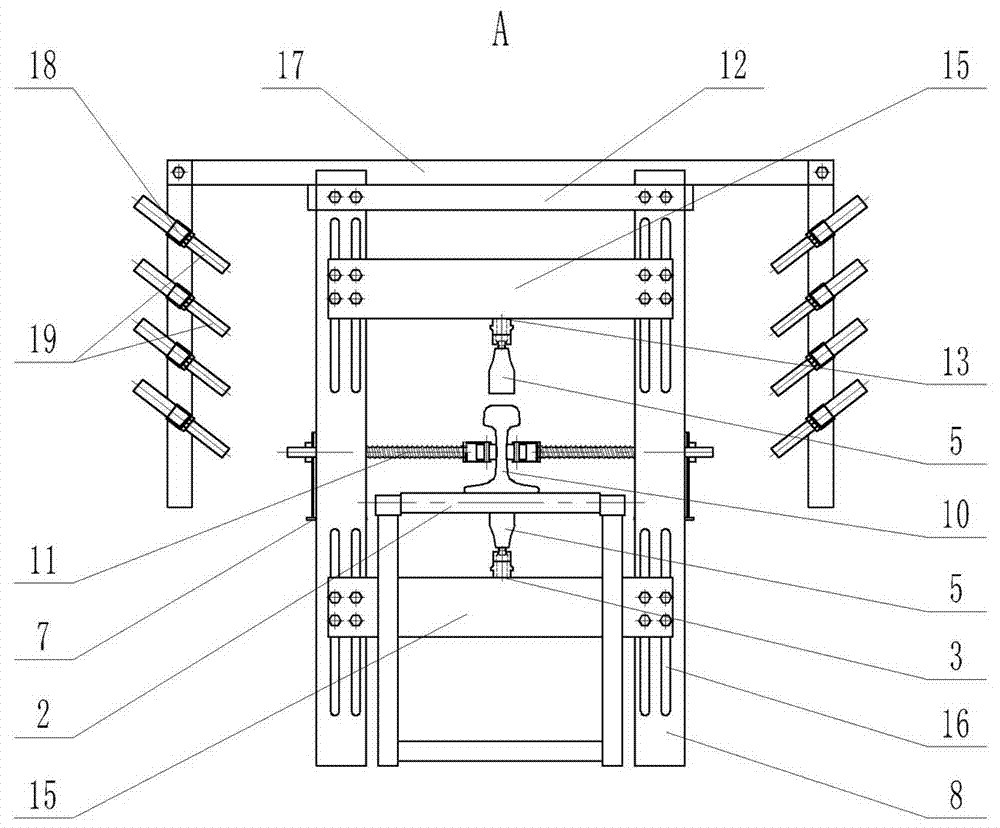

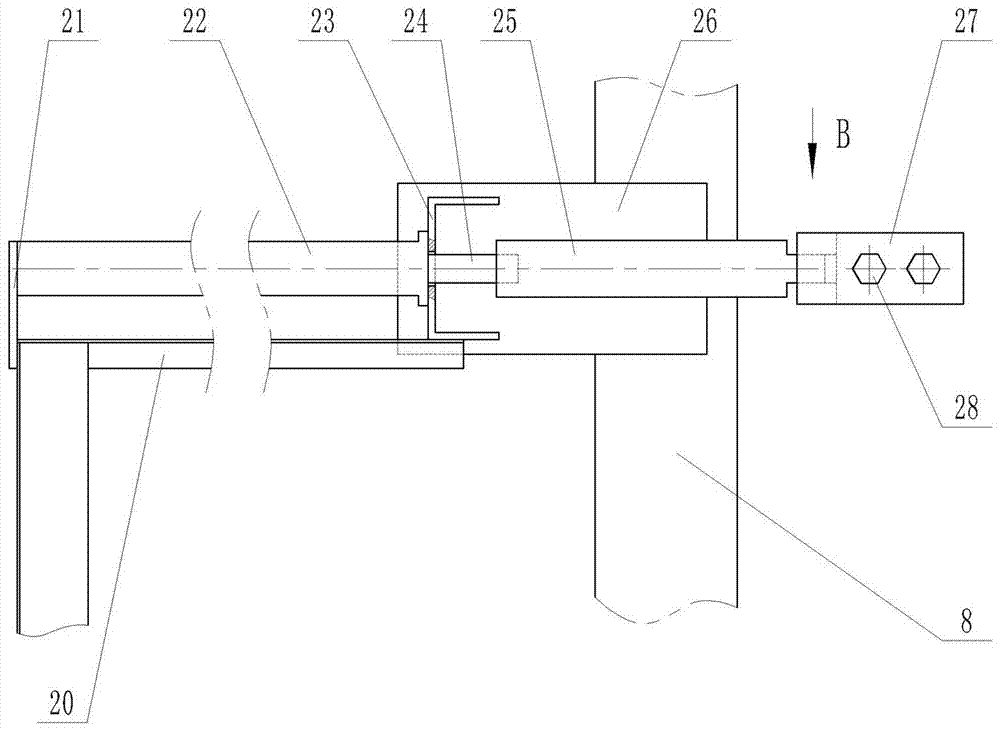

[0023] according to Figure 1-8The specific structure of the present invention will be described in detail. The overall air-cooled quenching experimental device for rails includes a support frame 1 enclosed by columns 8 and connecting beams, wherein the connecting beams include an upper connecting beam 12 arranged on the upper part of the supporting frame 1, and a middle connecting beam arranged in the middle of the supporting frame 1. Beam 7. The inside of the support frame 1 is provided with a horizontally arranged transmission roller table 2 for reciprocating sliding of the quenched steel rail 10; above the transmission roller table 2 is provided with an upper air cooling device 13 for cooling the head of the quenched steel rail 10, and the upper air cooling device 13 is composed of an upper sub-air box 14 with an upper part provided with an air inlet port 6, and the lower part of the upper sub-air box 14 is provided with several groups of blowing assemblies 5 arranged alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com