Steel rail damping fastener used for depot line of metro depot

A technology for damping fasteners and rails, which is applied in the directions of rails, fixed rails, roads, etc., can solve the problems of increasing the amount of rail buffer sinking, environmental vibration pollution, etc., and meets the limit of installation conditions and the height of fasteners. , The effect of ensuring driving safety and high-level vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

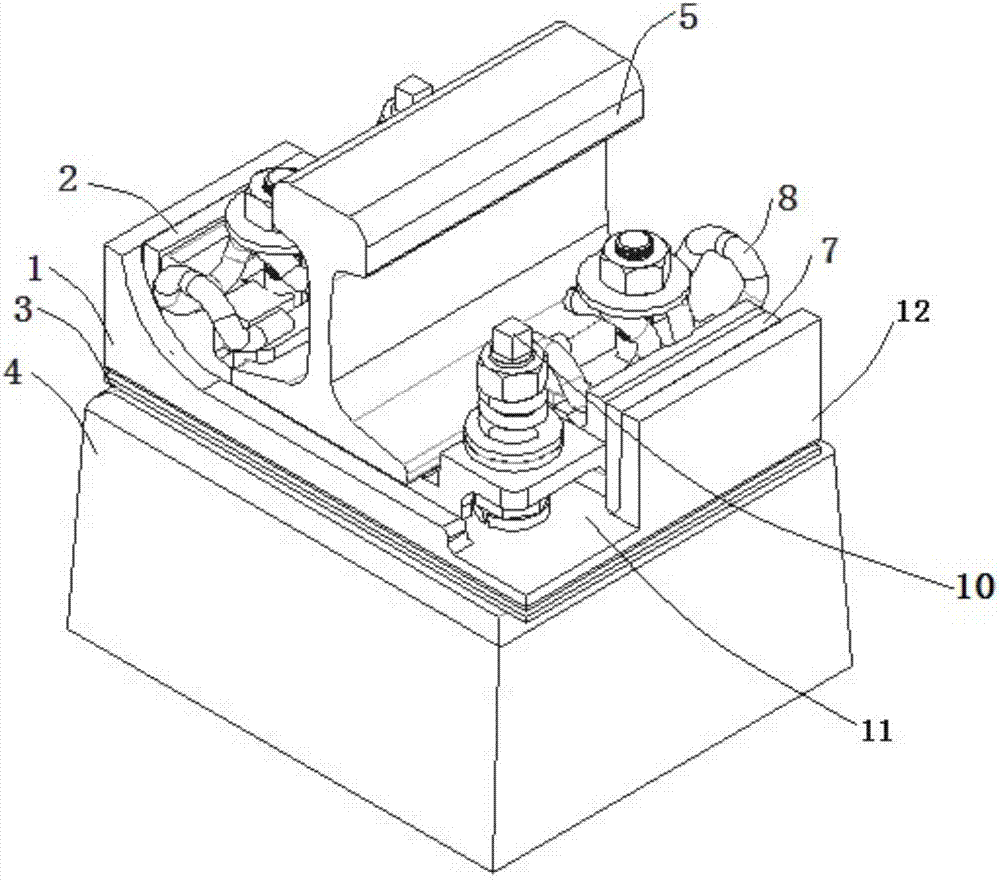

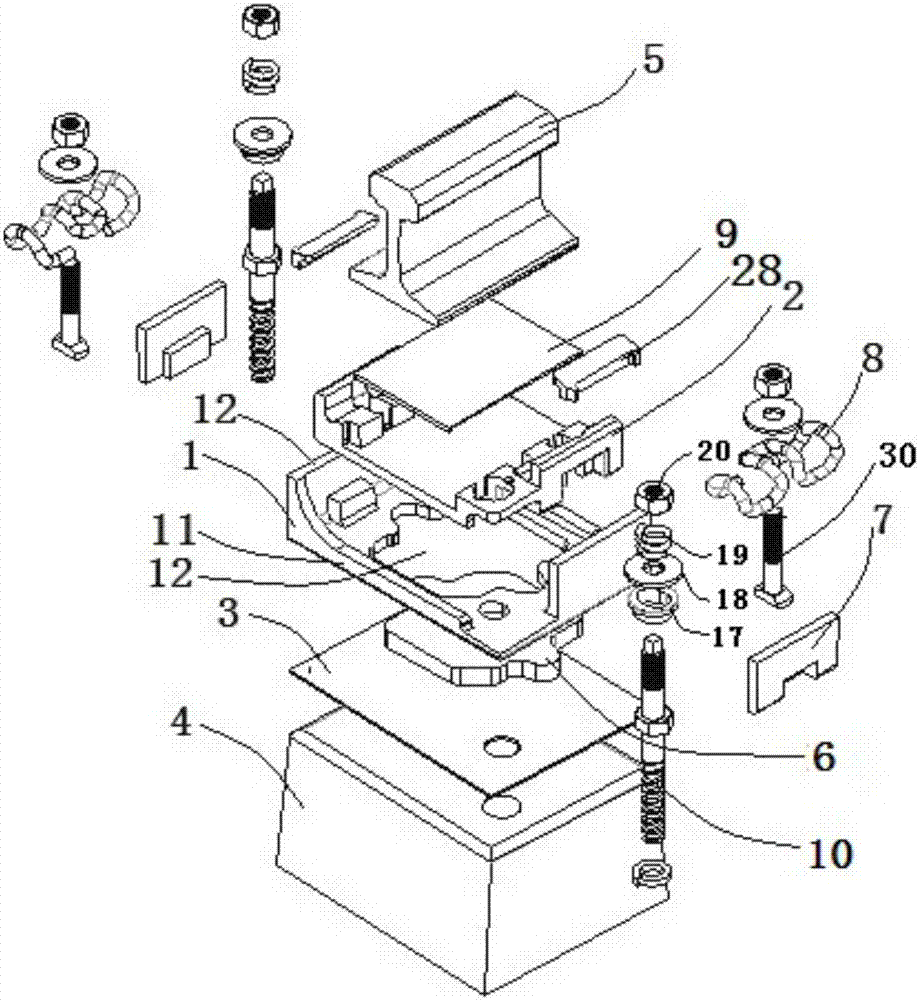

[0026] A rail vibration damping fastener used for the inner line of the subway depot, the structure is as follows figure 1 , figure 2 As shown, the rail damping fasteners include:

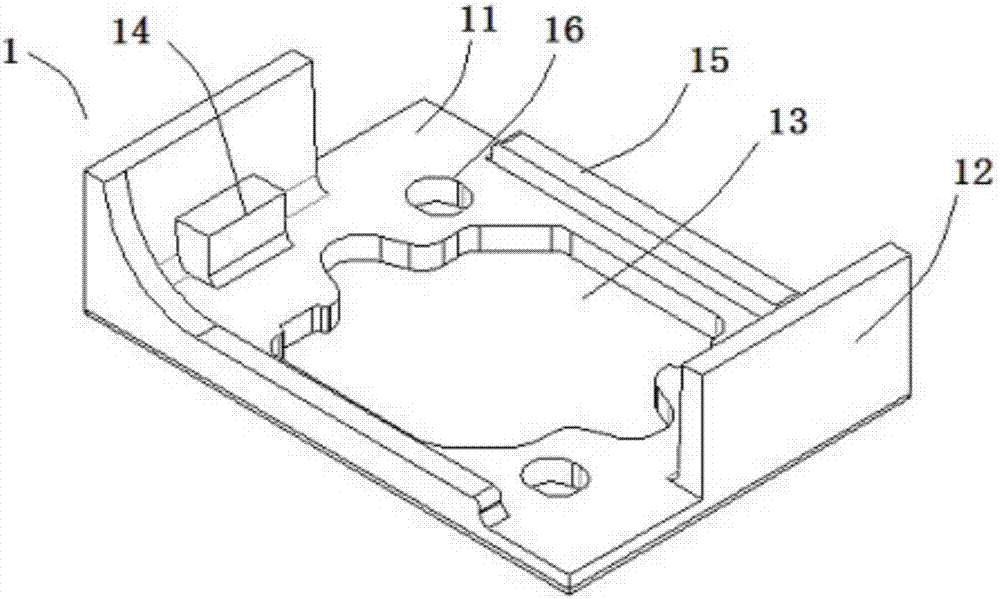

[0027] The base 1 is arranged on the sleeper 4. The base 1 has a base iron backing plate 11 and a shoulder 12 extending laterally from the base iron backing plate. The shoulder 12 is used to limit the lateral direction of the floating iron backing plate 2 Displacement, the base iron backing plate 11 is provided with a Chinese-shaped cavity 13; the under-board backing plate 3 is clamped between the base iron backing plate 11 and the sleeper 4; the base iron backing plate 11 and the under-board backing plate 3 pass through the double 10 nails on the head screw track are fastened on the sleeper 4;

[0028] The vibration isolation pad 6 is clamped between the iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com