Nanometer high polymer polylactic acid composite material and preparation method thereof

A nano-polymer and composite material technology, which is applied in the field of nano-polymer polylactic acid composite materials and its preparation, can solve the problems of polylactic acid product deformation, inability to contact with high-temperature items, unfavorable long-distance transportation, etc., and achieve high heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

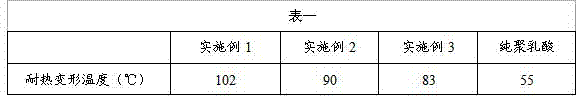

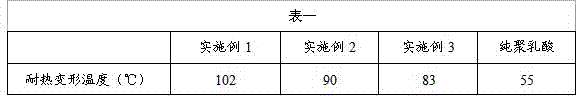

Examples

Embodiment 1

[0014] (1) Dry polylactic acid, nano-polycarbonate, and nano-polymethyl methacrylate in vacuum at 50°C for 8 hours to remove moisture;

[0015] (2) The above-mentioned dried polylactic acid, nano polycarbonate, nano polymethyl methacrylate, hydrolysis inhibitor carbodiimide, anti-aging agent hindered amine antioxidant, antioxidant four (β- (3,5 di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, etc. are stirred in a dry high-speed mixer according to the weight ratio to make it evenly mixed, and then reacted in a twin-screw extruder, the screw The rotation speed is 180rpm, the extrusion temperature is 210°C, the product is air-cooled, pelletized, and vacuum-dried to obtain heat-resistant polylactic acid masterbatch.

[0016] Among them, weight percent: polylactic acid content is 88.9%, nano polycarbonate 5%, nano polymethyl methacrylate 5%, hydrolysis inhibitor DIC content is 0.5%, antiaging agent hindered amine antioxidant content is 0.5% %, the antioxidant tet...

Embodiment 2

[0018] (1) Vacuum dry polylactic acid and nano-polyoxymethylene at 70°C for 5 hours to remove moisture;

[0019] (2) The above-mentioned dried polylactic acid, nano-polyoxymethylene, hydrolysis inhibitor DCC, anti-aging agent hindered phenolic antioxidant, antioxidant (3,5-di-tert-butyl-4-hydroxyphenyl) Stearyl propionate etc. are stirred in a dry high-speed mixer according to the weight ratio to make it evenly mixed, and then reacted and extruded in a twin-screw extruder with a screw speed of 100rpm and an extrusion temperature of 190°C. Cold pelletizing and vacuum drying to obtain heat-resistant polylactic acid masterbatch.

[0020] Wherein, weight percent: wherein polylactic acid content is 93%, nano polyoxymethylene content 5%, hydrolysis inhibitor DCC content is 0.8%, melt enhancer XDI content is 0.7%, antioxidant (3,5-di-tert-butyl The content of stearyl-4-hydroxyphenyl) propionate is 0.5%.

Embodiment 3

[0022] (1) Vacuum dry polylactic acid and nano-nylon 6 at 80°C for 3 hours to remove moisture;

[0023] (2) The above-mentioned dried lactic acid, nanometer nylon 6, hydrolysis inhibitor TIC, anti-aging agent benzotriazole light stabilizer, antioxidant β-(3,5-di-tert-butyl-4-hydroxy Phenyl) cyclohexyl propionate, etc. are stirred in a dry high-speed mixer according to the weight ratio to make it evenly mixed, and then reacted and extruded in a twin-screw extruder, the screw speed is 25rpm, and the extrusion temperature is 180°C , the product is air-cooled, pelletized, and vacuum-dried to obtain heat-resistant polylactic acid masterbatches.

[0024] Among them, the weight percentage: the content of polylactic acid is 96%, the content of nanometer nylon 6 is 1%, the content of anti-aging agent benzotriazole light stabilizer is 1%, the content of melt enhancer TDI is 1%, and the content of antioxidant β -(3,5-di-tert-butyl-4-hydroxyphenyl)cyclohexyl propionate content is 1%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com