Dispersed precipitated phase strengthened austenitic stainless steel with high Cr and high Ni and thermal processing method

A technology of austenitic stainless steel and dispersion precipitation, which is applied in the field of materials to achieve the effect of improving anti-irradiation swelling performance, increasing high temperature strength and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

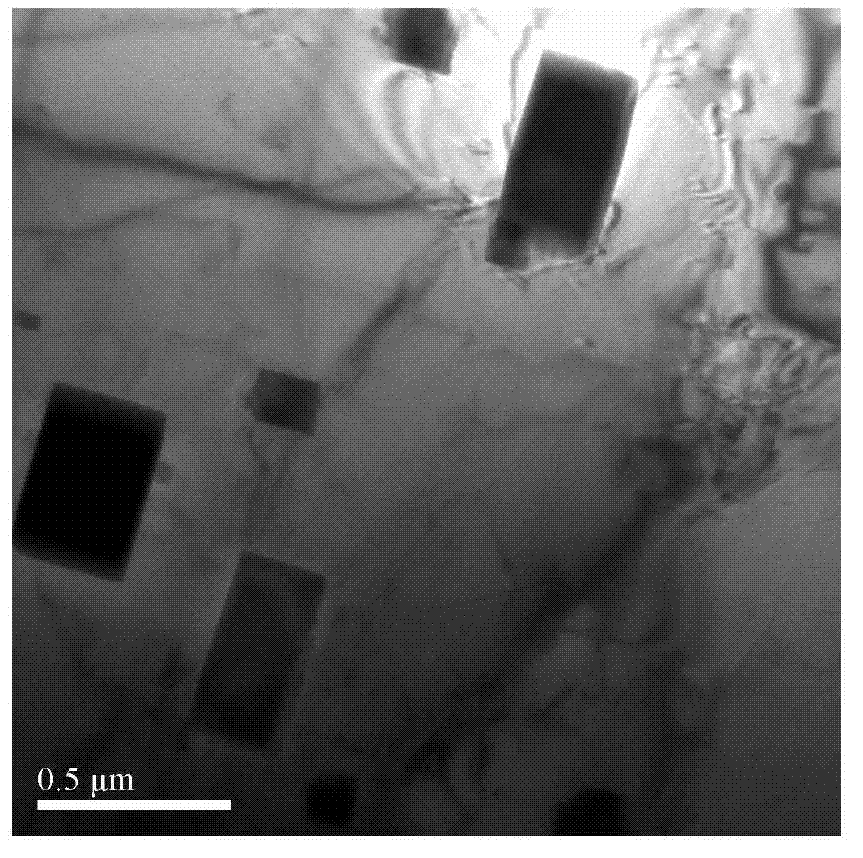

[0020] Example 1: Austenitic steel containing Mn and Ti, W, V and Zr

[0021] The designed composition system is: Fe-22Cr-21Ni+0.6Ti+0.6Zr+0.5W+0.5V+1.5Mn+0.8Si+0.10C (wt.%). The raw material is a commercially pure alloy, which is smelted and poured according to the above method. Then it is forged into a rectangular parallelepiped at a high temperature of 950-1200°C, which is convenient for processing and testing. Using a forging ratio of 3:1, the sample size after forging is: 200mm×140mm×30mm. Then the forged steel samples were subjected to high-temperature rolling, the starting rolling temperature was 1190 °C, the final rolling temperature was above 1030 °C, and rolled in four passes. The total reduction rate of hot rolling was 80%. The samples processed by heat deformation were solution treated at 1150°C and held for 50 minutes; then quenched immediately; followed by high-temperature annealing at 1050°C, held for 3 hours, and then cooled in the furnace or air to room te...

Embodiment 2

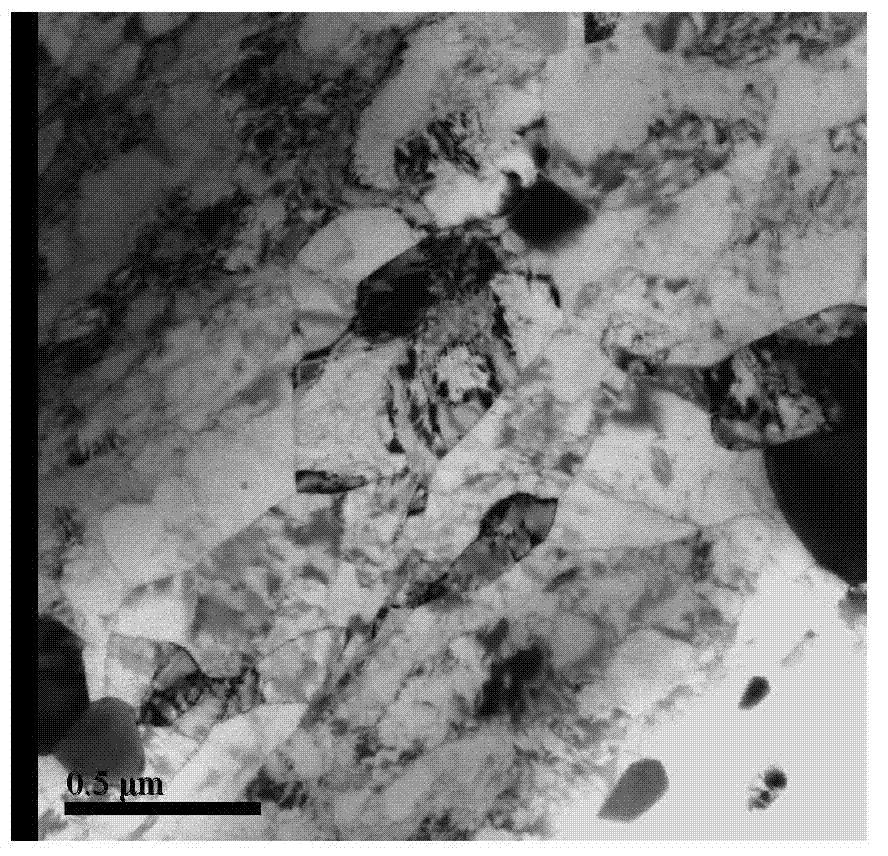

[0023] Example 2 : Austenitic steel containing Mo and Ti, W, V and Zr

[0024] The designed composition system is: Fe-28Cr-18Ni+0.4Ti+0.4Zr+0.3Mo+0.3V+0.5Si+0.08C (wt.%). The raw material and smelting method are similar to the above method. The initial forging temperature is slightly higher than that of Example 1, and the sample size after forging is: 200mm×140mm×30mm. Then the forged steel samples were subjected to high-temperature rolling, the rolling temperature was 1200°C, the final rolling temperature was above 1030°C, rolled in four passes, the total reduction rate of hot rolling was 80%, and the rolling was directly quenched and quickly cooled. The samples processed by heat deformation were solution treated at 1180°C and held for 40 minutes; then quenched immediately; followed by high-temperature annealing at 1050°C, held for 3.5 hours, and then cooled in the furnace or air to room temperature. Compared with the commercial steel, the strength of the obtained sample ...

Embodiment 3

[0026] Example 3 : Austenitic steel containing Mn and a small amount of Ti, W, V and Zr

[0027] The raw materials and the smelting process are as described above. The designed composition system is: Fe-25Cr-20Ni+0.2Ti+0.2Zr+0.1W+0.15V+1.2Mn+0.6Si+0.1C (wt.%). Take about 1 / 3 of the above steel ingots for forging. The initial temperature of forging is 1180°C, the end temperature is 900°C, and the forging ratio is 3:1. The sample size after forging is: 200mm×140mm×35mm. Then the forged steel samples were subjected to high-temperature rolling, the rolling temperature was 1200°C, the final rolling temperature was above 1030°C, rolled in four passes, the total reduction rate of hot rolling was 80%, and the rolling was directly quenched and quickly cooled. The samples processed by heat deformation were solution treated at 1160°C and held for 60 minutes; then quenched immediately; followed by high-temperature annealing at 1050°C, held for 3.5 hours, and then cooled in the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com