Technique for treating fermentation wastewater by microbial fuel cell

A fuel cell, fermentation wastewater technology, applied in biochemical fuel cells, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of lack of active groups, accelerated microbial attachment, hindered conductive microbial attachment and film formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

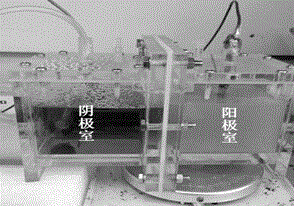

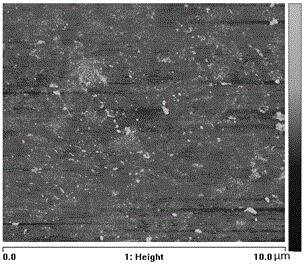

[0042] 1) Use a blank conductive glass with a length of 5cm and a width of 4cm as the cathode and anode.

[0043] 2) The composition of anolyte for microbial fuel cell treatment of fermented wastewater: 10g of pond sludge, 200ml of fermented wastewater, 300ml of microbial acclimation solution (every 500ml of anolyte) in a constant temperature incubator at 37 o C cultured for 3 days. Catholyte composition: 50mM potassium ferricyanide dissolved in 1000ml water.

[0044] 3) Assembly of the microbial fuel cell: the external resistance is 1000 ohms, and the UT803 data acquisition card is used, and the electrochemical activity measurement of the anode biofilm of the microbial fuel cell is measured by an electrochemical workstation.

[0045] 4) Use conductivity to test the conductivity and total solids of the cathode and anode substrates before the assembly of the microbial fuel cell and after electricity generation, and test the pH value of the cathode and anode before the assembly...

Embodiment 2

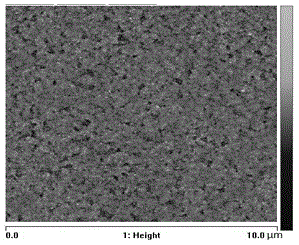

[0048] 1) The multilayer film-modified conductive glass with a length of 5cm and a width of 4cm (guaranteed length > width) is used as the anode, and a blank conductive glass is used as the cathode.

[0049] 2) The composition of anolyte for microbial fuel cell treatment of fermented wastewater: 10g of pond sludge, 200ml of fermented wastewater, 300ml of microbial acclimation solution (every 500ml of anolyte) in a constant temperature incubator at 37 o C cultured for 3 days. Catholyte composition: 50mM potassium ferricyanide dissolved in 1000ml water.

[0050] 3) Assembly of the microbial fuel cell: the external resistance is 1000 ohms, and the UT803 data acquisition card is used, and the electrochemical activity measurement of the anode biofilm of the microbial fuel cell is measured by an electrochemical workstation.

[0051] 4) Use conductivity to test the conductivity and total solids of the cathode and anode substrates before the assembly of the microbial fuel cell and af...

Embodiment 3

[0054] 1) Use a blank carbon cloth with a length of 5cm and a width of 4cm (guaranteed length > width) as the cathode and anode.

[0055] 2) The composition of anolyte for microbial fuel cell treatment of fermented wastewater: 10g of pond sludge, 200ml of fermented wastewater, 300ml of microbial acclimation solution (every 500ml of anolyte) in a constant temperature incubator at 37 o C cultured for 3 days. Catholyte composition: 50mM potassium ferricyanide dissolved in 1000ml water.

[0056] 3) Assembly of the microbial fuel cell: the external resistance is 1000 ohms, the MPS-010602 data acquisition card is used, and the electrochemical activity of the anode biofilm of the microbial fuel cell is measured by an electrochemical workstation.

[0057] 4) Use conductivity to test the conductivity and total solids of the cathode and anode substrates before the assembly of the microbial fuel cell and after electricity generation, and test the pH value of the cathode and anode before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com