Low-energy-consumption preparation method for black phosphorus single crystals

A technology of low energy consumption and black phosphorus, which is applied in the preparation of phosphorus, etc., can solve the problems of high reaction temperature and high requirements for reaction devices, and achieve the effects of high purity, reduced energy consumption, and lowered sublimation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

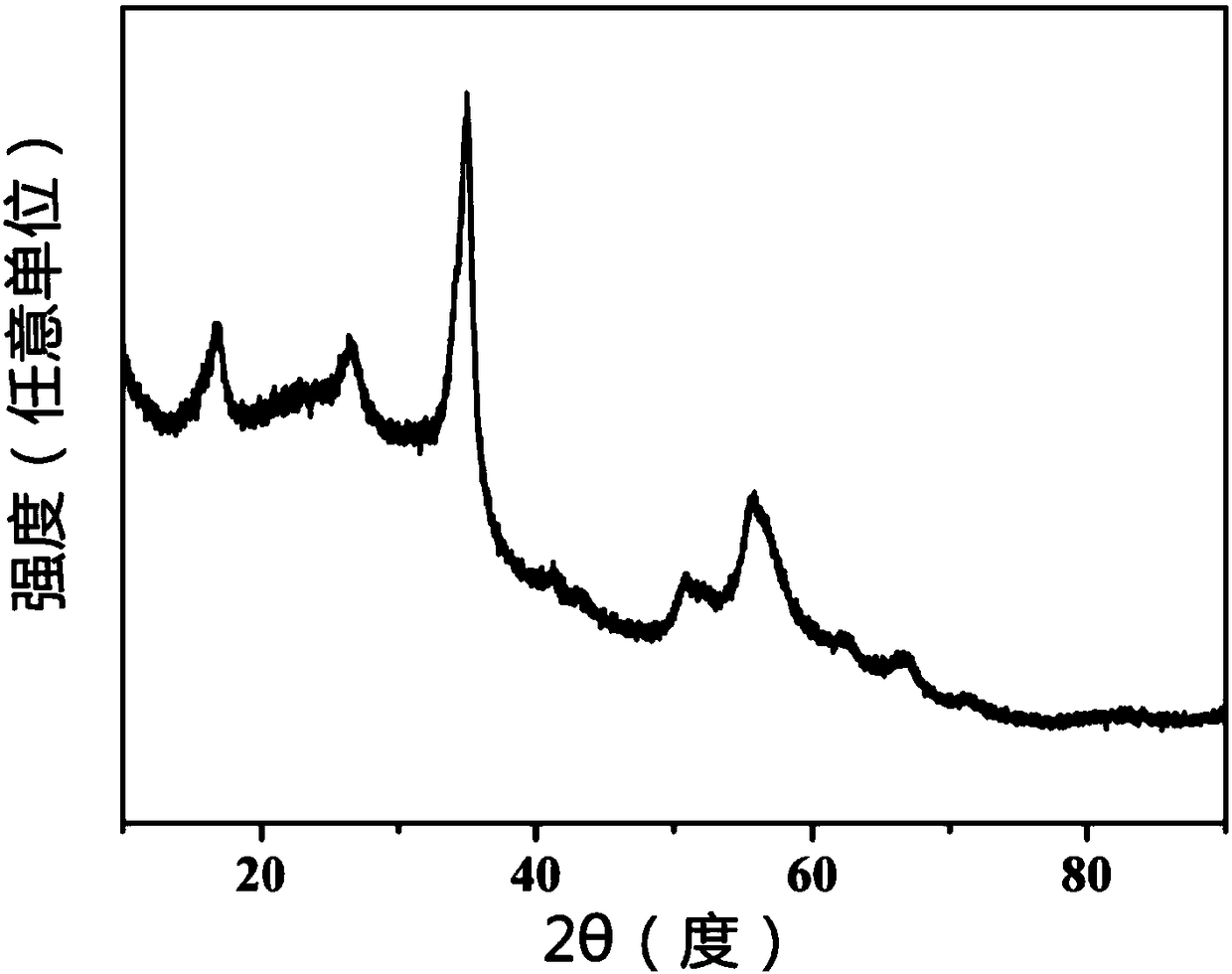

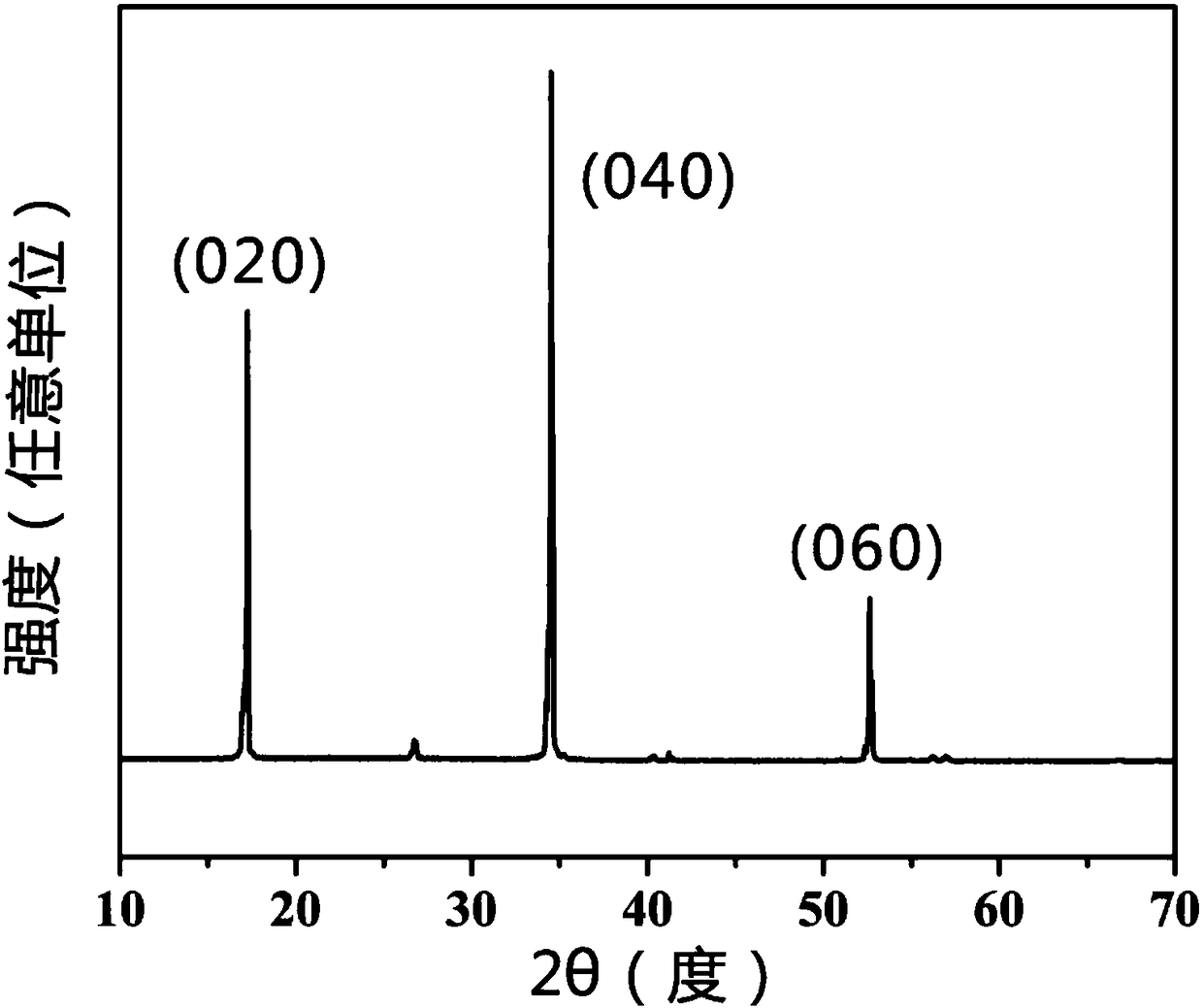

[0026] Weigh 5 g of 99.999 mass % red phosphorus, add 160 g of stainless steel balls, and ball mill for 7 hours at a rotational speed of 1500 r / min to collect crude black phosphorus powder.

[0027] Weigh 300mg of the above crude black phosphorus powder, 12mg of tin elemental substance, and 6mg of tin tetraiodide, put them in a quartz tube with a length of about 10cm, evacuate until the pressure in the quartz tube is 0.1Pa, and seal the quartz tube. Put the sealed quartz tube in a muffle furnace, raise it from room temperature to 480°C over 60 minutes, keep it warm for 2 hours, and then start to cool down. The cooling process is from 480°C to 300°C over 12 hours, and then down to 100°C over 10 hours. , and then cooled to room temperature over 1 h.

Embodiment 2

[0029] Weigh 2 g of 99.999 mass % red phosphorus, add 120 g of stainless steel balls, and ball mill for 7 hours at a speed of 1000 r / min to collect crude black phosphorus powder.

[0030] Weigh 300mg of the above crude black phosphorus powder, 12mg of tin elemental substance, and 6mg of tin tetraiodide, put them in a quartz tube with a length of about 10cm, evacuate until the pressure in the quartz tube is 0.1Pa, and seal the quartz tube. Put the sealed quartz tube in a muffle furnace, raise it from room temperature to 480°C over 60 minutes, keep it warm for 2 hours, and then start to cool down. The cooling process is from 480°C to 300°C over 12 hours, and then down to 100°C over 10 hours. , and then cooled to room temperature over 1 h.

Embodiment 3

[0032] Weigh 5 g of 99.999 mass % red phosphorus, add 160 g of stainless steel balls, and ball mill for 7 hours at a rotational speed of 1500 r / min to collect crude black phosphorus powder.

[0033] Weigh 300mg of the above crude black phosphorus powder, 12mg of tin elemental substance, and 6mg of tin tetraiodide, put them in a quartz tube with a length of about 10cm, evacuate until the pressure in the quartz tube is 0.1Pa, and seal the quartz tube. Put the sealed quartz tube in the muffle furnace, rise from room temperature to 400°C over 60 minutes, keep it warm for 2 hours, and then start to cool down. The cooling process is from 400°C to 300°C over 12 hours, and then down to 100°C over 12 hours. , and then cooled to room temperature over 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com