Method of preparing flocculating agent by utilizing sludge and application thereof

A flocculant and sludge technology, which is applied in the preparation of flocculants from sludge and its application fields, can solve the problems of large differences in the application cost of pretreatment effects, etc., to facilitate transportation and storage, improve flocculation activity, and accelerate the settlement of suspensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

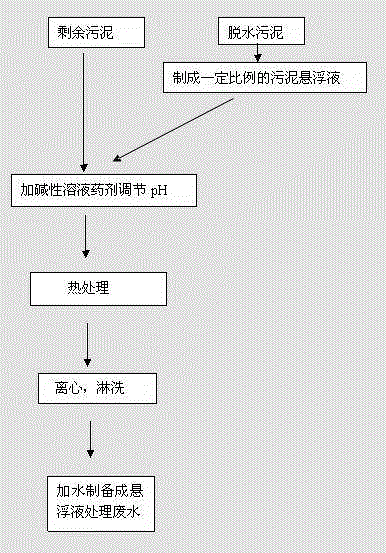

[0023] The method of using sludge to prepare flocculant, such as figure 1 As shown, the dewatered sludge is made into a sludge mixture with 6 times the mass of tap water, and the pH is adjusted to 9.0~12.0 with an alkaline solution. It is centrifuged at a speed of 5000r / min, the supernatant is removed, the precipitate is used as a flocculant, the flocculant is washed 2-3 times with clean water, and a flocculant suspension of equal volume before centrifugation is prepared with clean water for use. The flocculation rate of the flocculant suspension to the kaolin suspension can reach 95.4%, and the turbidity removal rate of the dye wastewater is 83.1%.

Embodiment 2

[0025] The method of using sludge to prepare flocculant, such as figure 1 As shown, the remaining sludge suspension in the sewage treatment plant was left to stand to remove the supernatant, and then heated in a high-temperature and high-pressure sterilizer at 100-130°C for 30 minutes, stirred evenly and directly used for flocculation. The flocculant makes the sedimentation speed of the soil suspension 2~3 times of the original, and the turbidity removal rate of the activated carbon suspension can reach 92.6%, and the reaction time can be completed within 3 minutes.

Embodiment 3

[0027] Using sludge to prepare flocculant, use 10 times the mass of tap water to make a sludge mixture from dewatered sludge, adjust the pH to 10.0 with alkaline solution, keep it for 5 minutes, and then heat the reaction at about 90°C for 30 minutes, and the heating is completed , centrifuge it at a speed of 7000r / min, remove the supernatant, take the precipitate as a flocculant, wash the flocculant with water for 2-3 times, and use clean water to prepare a flocculant suspension of equal volume before centrifugation. use. The flocculation rate of the flocculant suspension to the kaolin suspension can reach 95.4%, and the turbidity removal rate of the dye wastewater is 84.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com