Saline and alkaline land improvement method

A saline-alkali land modification technology, which is applied in the direction of soil preparation, nitrate fertilizer, application, etc., can solve the problems such as poor improvement effect of saline-alkali land, and achieve the effect of preventing secondary salinization of soil, maintaining water and soil, and restoring vegetation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

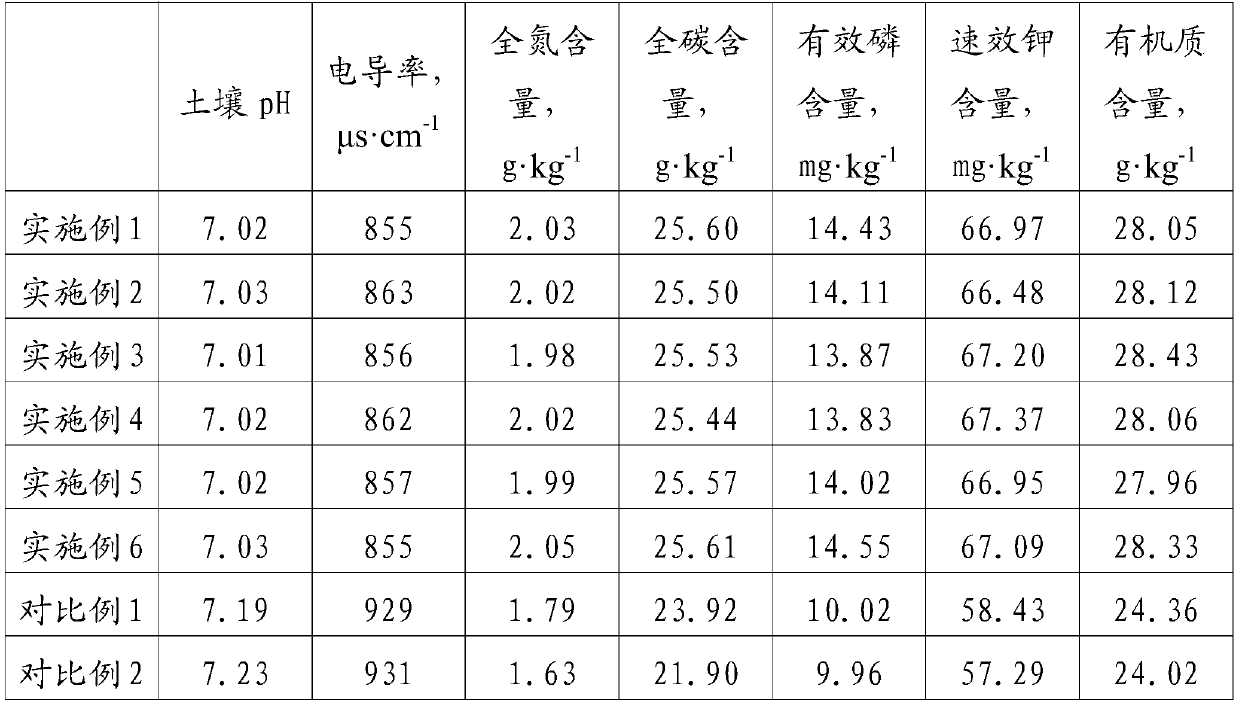

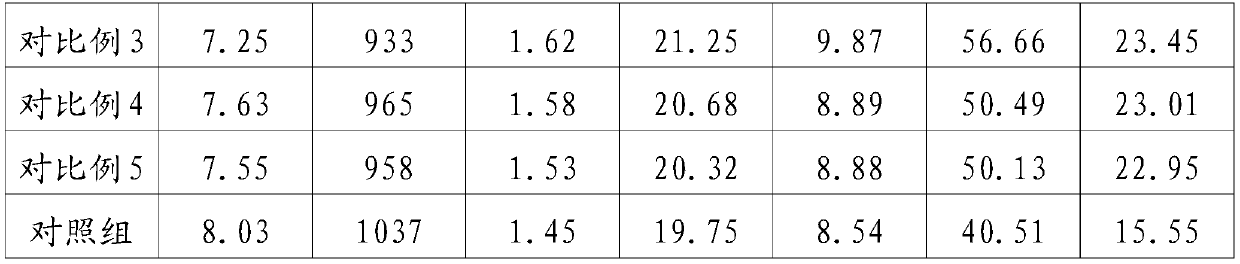

Examples

Embodiment 1

[0029] A method for improving saline-alkali land, comprising the following steps:

[0030] (1) Dissolve cellulose acetate in a mixed solvent composed of ethyl acetate and ethanol to obtain a mixed solution with a concentration of 0.08g / ml; mix 2g methylcellulose, 2.2g sodium citrate, 2ml span80, 18ml acetic acid Ethyl ester and 480ml of deionized water were mixed and stirred evenly to obtain a dispersion; the mixed solution was added dropwise to the dispersion, stirred while adding, and continued to stir and mix after the dropwise addition to obtain a suspension; the mixed solution was The volume ratio of the dispersion to the dispersion is 1:2; the suspension is stirred, evaporated and concentrated at 60°C; finally the obtained concentrate is filtered; the filtered solid is washed with deionized water and absolute ethanol in sequence, Finally dry to make cellulose acetate microspheres;

[0031] (2) Mix sodium alginate and deionized water to prepare a sodium alginate solution...

Embodiment 2

[0037] A method for improving saline-alkali land, comprising the following steps:

[0038] (1) Dissolve cellulose acetate in a mixed solvent composed of ethyl acetate and ethanol to obtain a mixed solution with a concentration of 0.08g / ml; mix 2.5g methylcellulose, 2.6g sodium citrate, 2ml span80, 48ml Ethyl acetate and 450ml of deionized water were mixed and stirred evenly to obtain a dispersion; the mixed solution was added dropwise to the dispersion, and stirred while adding dropwise, and continued to stir and mix after the dropwise addition to obtain a suspension; The volume ratio of the solution and the dispersion is 1:3; the suspension is stirred, evaporated and concentrated at 70°C; finally, the obtained concentrated solution is filtered; the filtered solid is washed with deionized water and absolute ethanol in sequence , and finally dried to obtain cellulose acetate microspheres;

[0039] (2) Mix sodium alginate and deionized water to prepare a sodium alginate solutio...

Embodiment 3

[0045] A method for improving saline-alkali land, comprising the following steps:

[0046] (1) Dissolve cellulose acetate in a mixed solvent composed of ethyl acetate and ethanol to obtain a mixed solution with a concentration of 0.09g / ml; mix 2.1g methylcellulose, 2.3g sodium citrate, 2ml span80, 28ml Ethyl acetate and 470ml of deionized water were mixed and stirred evenly to obtain a dispersion; the mixed solution was added dropwise to the dispersion, and stirred while adding, and continued to stir and mix after the addition was completed to obtain a suspension; The volume ratio of the solution to the dispersion is 1:2.2; the suspension is stirred, evaporated and concentrated at 65°C; finally, the obtained concentrated solution is filtered; the filtered solid is washed with deionized water and absolute ethanol in sequence , and finally dried to obtain cellulose acetate microspheres;

[0047] (2) Sodium alginate and deionized water are mixed to obtain a sodium alginate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com