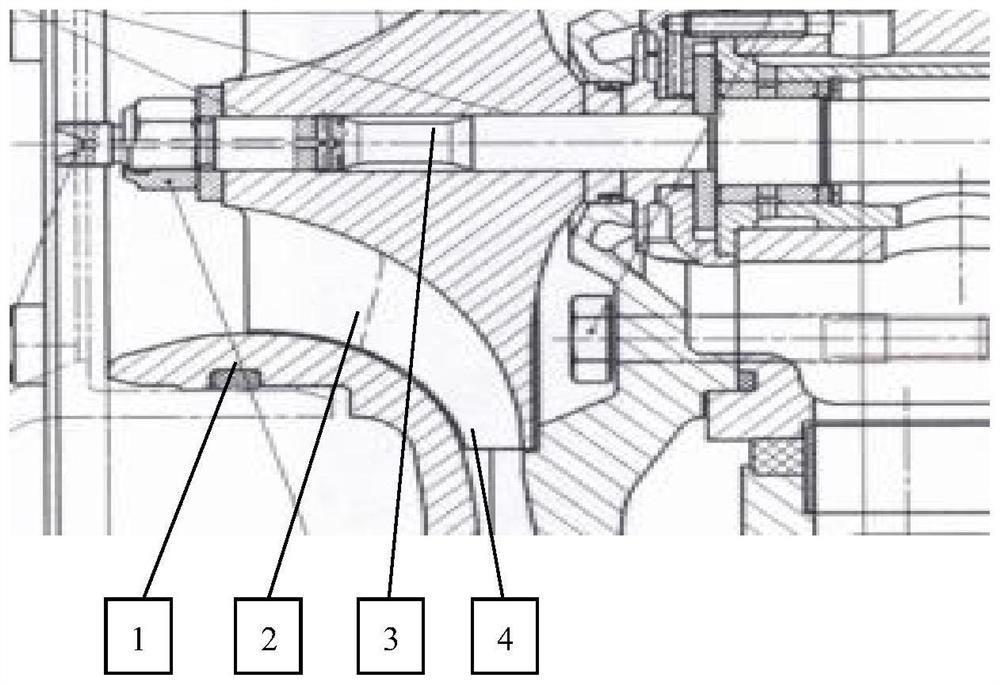

Machining method for compressor impeller of ZR series superchargers

A processing method and supercharger technology, applied to internal combustion piston engines, mechanical equipment, combustion engines, etc., can solve problems such as insufficient end face turning allowance, parts throwing out, loss of geometric accuracy, etc., to improve production efficiency and processing quality , stable clamping, and reduce the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

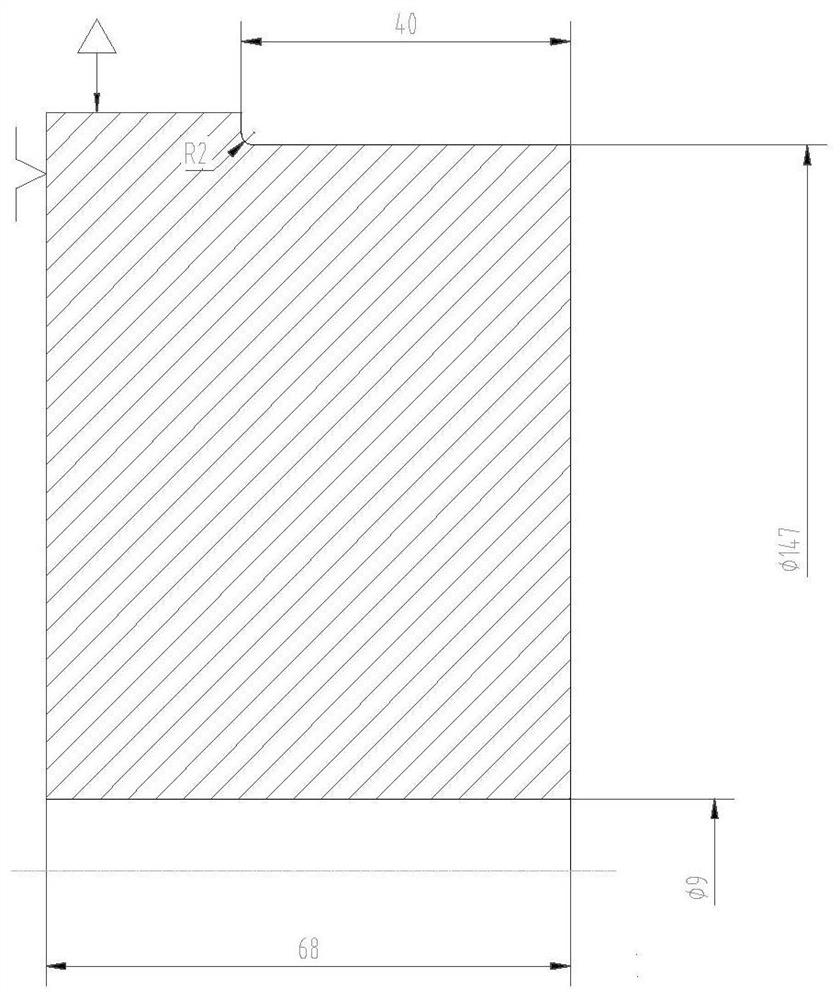

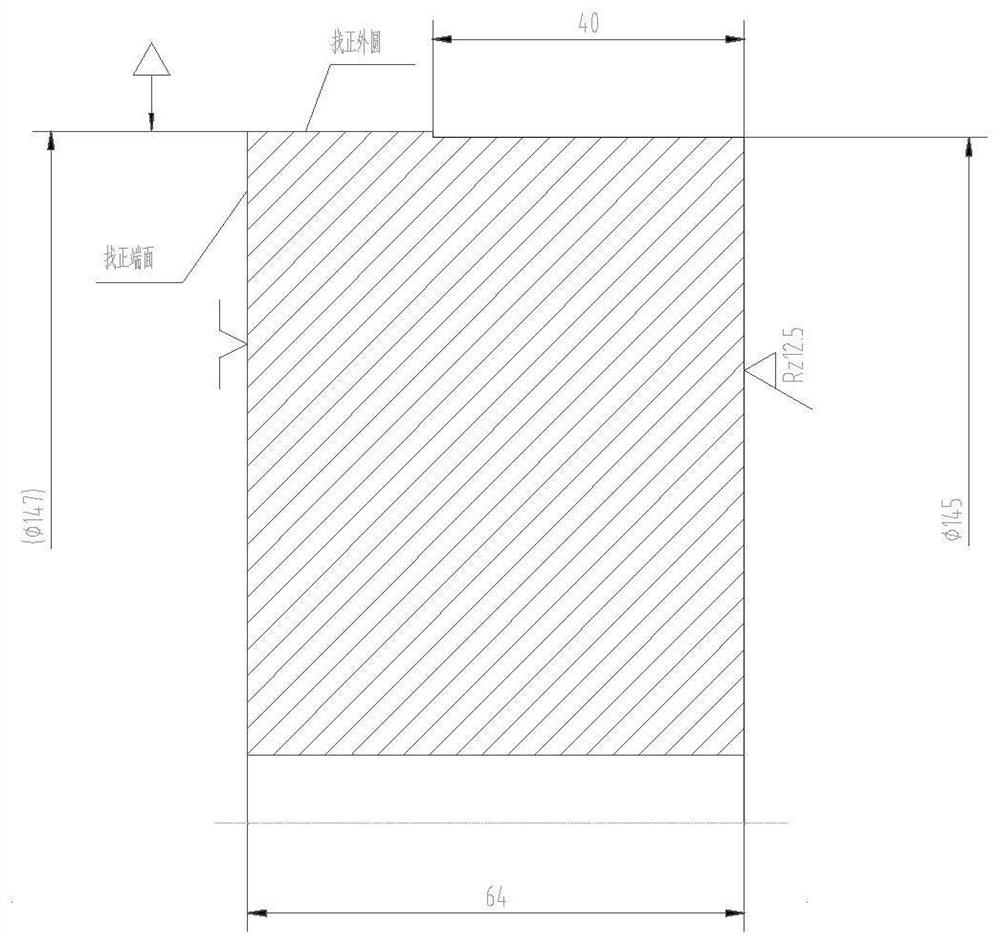

[0066] Theoretical basis;

[0067] a. During the milling process of the blades and flow channels of the compressor impeller, the excess material is forcibly removed from the part body by milling the part with the milling cutter, so that the material stress will be lost after milling, and at the same time due to the milling force, clamping force, etc. Therefore, no matter how to adjust the milling parameters, change the milling force and clamping method, etc., the deformation of the meridian surface cannot be completely eliminated, and the accuracy requirements of the meridian surface of the part cannot be met.

[0068] b. Change the machining plan, redistribute the machining allowances, change the final machining of the atomic meridian surface to semi-finishing machining, and leave enough finishing allowances. After milling, the stress of the material is released, and the strain and deformation of the parts are all eliminated. After that, the final machining (finishing) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com