Closed oil film visualization device capable of measuring leakage of reciprocating sealing piston

A sealed piston and closed technology, which is applied in the field of closed oil film visualization devices, can solve the problems that the quantitative relationship of the sealed area cannot be obtained, the influence of the liquid temperature on the sealed oil film cannot be considered, and the conditions for determining the liquid pressure cannot be provided, so as to prevent damage, Guarantee the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

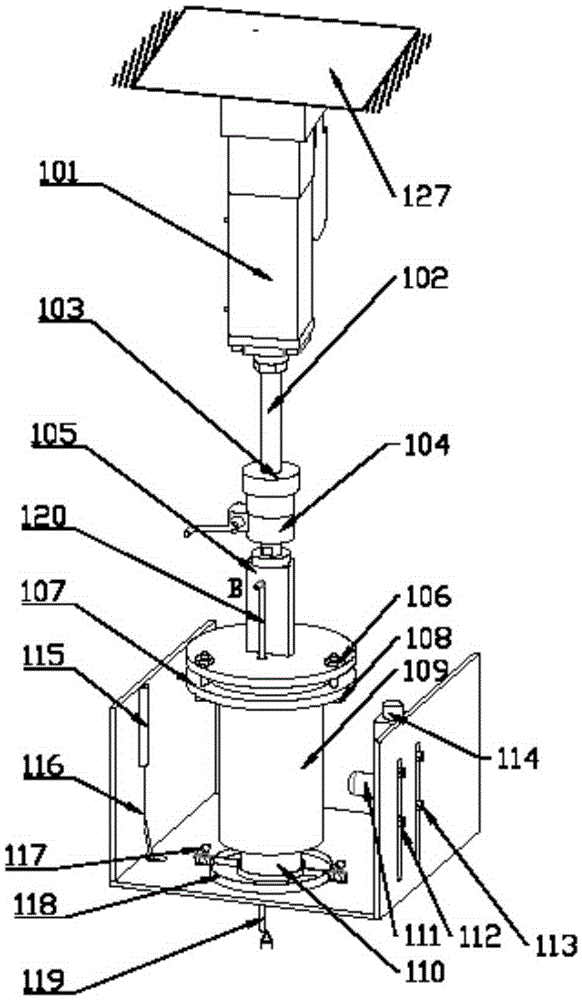

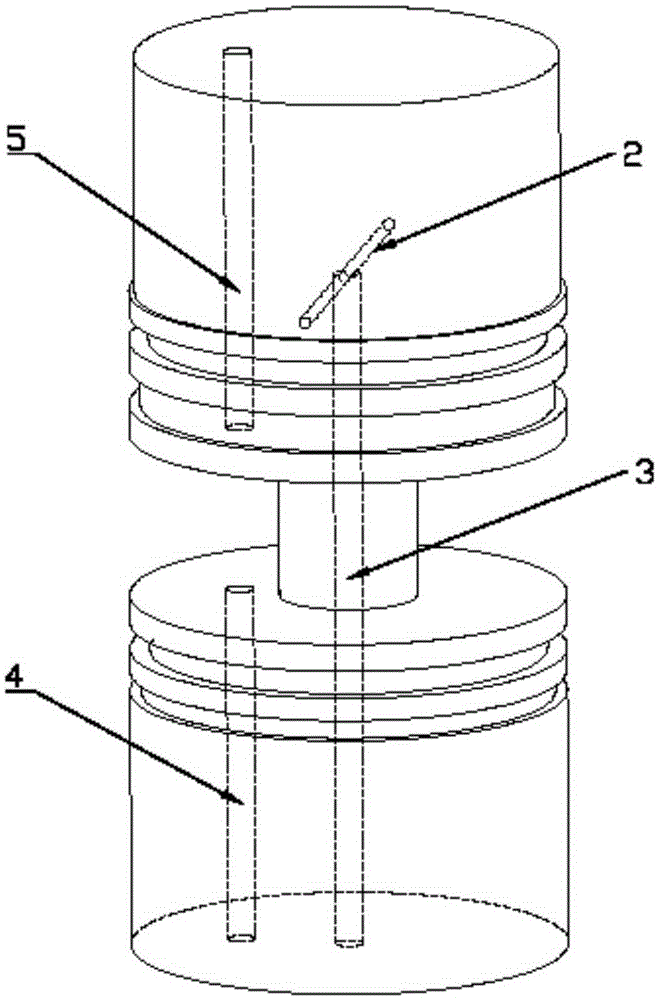

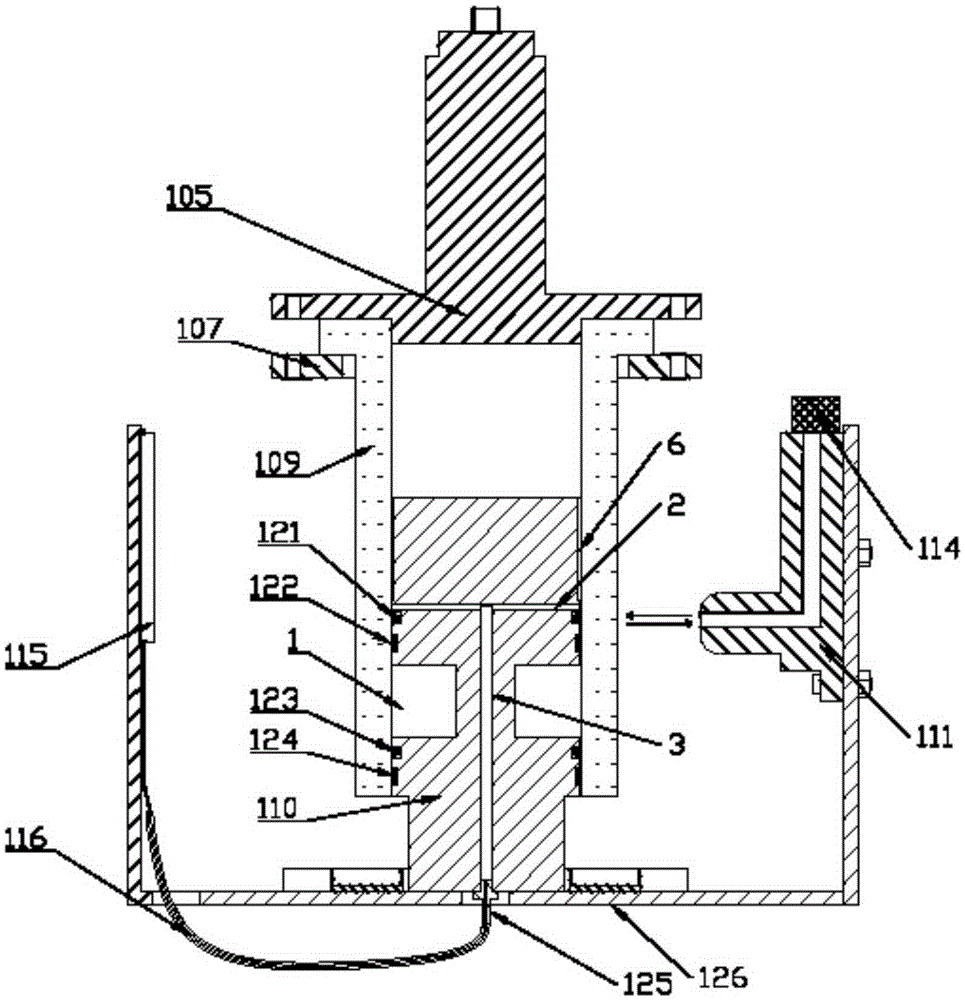

[0035] The invention includes a platform visualization mechanism and an oil supply system. like figure 1 As shown, the platform visualization mechanism includes a top plate 127, a base frame 126, a linear actuator 101, a tension sensor 104, a piston 110, and a transparent cylinder 109. The linear actuator 101 is suspended and fixed on the top plate 127. The linear actuator 101 The output rod 102 is downwardly connected to one end of the tension pressure sensor 104 through the sensor connector 103, and the other end of the tension pressure sensor 104 is fixedly connected to the transparent cylinder 109 through the transparent cylinder connector 105, and the bottom of the piston 110 is fixed on the bottom surface of the base frame 126. The piston 110 is installed in the inner cavity of the lower end of the transparent cylinder 109; the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com