Extension type quasi-zero stiffness vibration isolator and implementation method thereof

A quasi-zero stiffness, vibration isolator technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of low natural frequency and inability to realize the vibration isolation system, achieve simple structure and avoid loss. Stable and easy to debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

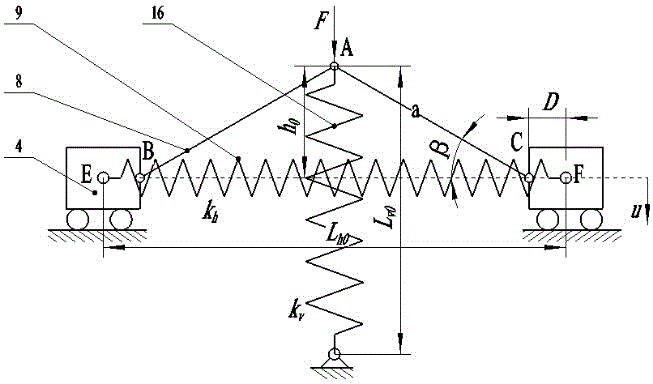

[0035] This embodiment provides a tensile quasi-zero stiffness vibration isolator, such as Figure 5 to Figure 7 As shown, it includes base 1, main spring 16, adjusting nut 17, bolt seat 18, sleeve cover 12, stage 11, tension spring 9, connecting rod 8, slider 4, guide rail 3, cross bar 5, upper Hinge seat 7, side hinge seat 10 and support seat 2; Described base 1 middle part is equipped with described bolt seat 18 and described adjusting nut 17 for adjusting described main spring 16 to move up and down; Described main spring 16 is Positive stiffness spring, the upper and lower ends of the main spring 16 are positioned and supported by the cover 12 and the adjusting nut 17 respectively; The tension spring 9, the connecting rod 8, the slide block 4 and the guide rail 3 form a negative stiffness mechanism, and one end of the connecting rod 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com