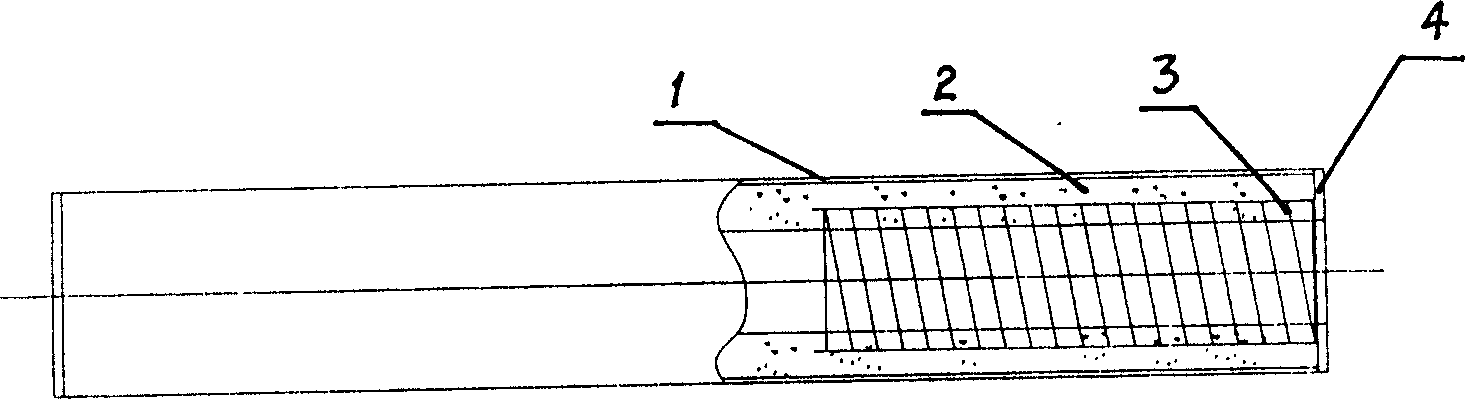

Centrifugal tubular pile with concrete of thin-wall steel pipe and production thereof

A technology of concrete pipe piles and thin-walled steel pipes, which is applied to sheet pile walls, reinforced molding, construction, etc., can solve the problems of increased construction costs, inconvenient construction, and high costs, so as to save production costs, enhance anti-shock ability, Combined with strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The wall thickness of the steel pipe is: 6mm, and the concrete mix ratio is as follows:

[0021] Ordinary 42.5 grade cement: 515kg / m 3 , yellow sand: 640kg / m 3 , Gravel (5-25mm): 1216kg / m 3 , water: 100kg / m 3 , Water reducer: 10.7kg / m 3 .

[0022] The specific production method is: put the raw materials of the above mixing ratio into the mixer, the mixing time is 180 seconds, and the measured slump is 80mm. They are: low speed for 120 seconds, medium speed for 180 seconds, medium and high speed for 120 seconds, and high speed for 420 seconds. The maintenance adopts two forms of normal pressure steam health preservation and high pressure steam health preservation: a. Normal pressure steam health preservation: rest for 2 hours - heat up for 2 hours ——Constant temperature for 5 hours——Cooling temperature for 1 hour; b. High-pressure steam health preservation: heating up in the autoclave for 2 hours——Constant temperature for 4 hours——Cooling for 3 hours——...

Embodiment 2

[0023] Embodiment 2: The wall thickness of the steel pipe is: 5.9mm, and the concrete mix ratio is as follows:

[0024] Ordinary 42.5 grade cement: 515kg / m 3 , yellow sand: 640kg / m 3 , Gravel (5-25mm): 1216kg / m 3 , water: 100kg / m 3 , Water reducer: 10.7kg / m 3 .

[0025] The specific production method is: put the raw materials of the above mixing ratio into the mixer, the mixing time is 180 seconds, and the measured slump is 80mm. They are: low speed for 120 seconds, medium speed for 180 seconds, medium and high speed for 120 seconds, and high speed for 420 seconds. The maintenance adopts two forms of normal pressure steam health preservation and high pressure steam health preservation: a. Normal pressure steam health preservation: rest for 2 hours - heat up for 2 hours ——Constant temperature for 5 hours——Cooling temperature for 1 hour; b. High-pressure steam health preservation: heating up in the autoclave for 2 hours——Constant temperature for 4 hours——Cooling for 3 hours...

Embodiment 3

[0026] Embodiment 3: The wall thickness of the steel pipe is: 5.8mm, and the concrete mix ratio is as follows:

[0027] Ordinary 42.5 grade cement: 510kg / m 3 , yellow sand: 616kg / m 3 , Gravel (5-25mm): 1197kg / m 3 , water: 149kg / m 3 , Water reducer: 10.3kg / m 3 .

[0028] The specific production method is: put the raw materials of the above mixing ratio into the mixer, the mixing time is 180 seconds, and the measured slump is 80mm. They are: low speed for 120 seconds, medium speed for 180 seconds, medium and high speed for 120 seconds, and high speed for 420 seconds. The maintenance adopts two forms of normal pressure steam health preservation and high pressure steam health preservation: a. Normal pressure steam health preservation: rest for 2 hours - heat up for 2 hours ——Constant temperature for 5 hours——Cooling temperature for 1 hour; b. High-pressure steam health preservation: heating up in the autoclave for 2 hours——Constant temperature for 4 hours——Cooling for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com