Horizontal force supporting pile and production process thereof

A production process and horizontal force technology, applied in sheet pile walls, manufacturing tools, infrastructure engineering, etc., can solve problems such as steel bar fracture and poor ductility, and achieve the effects of improved ductility, low cost, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

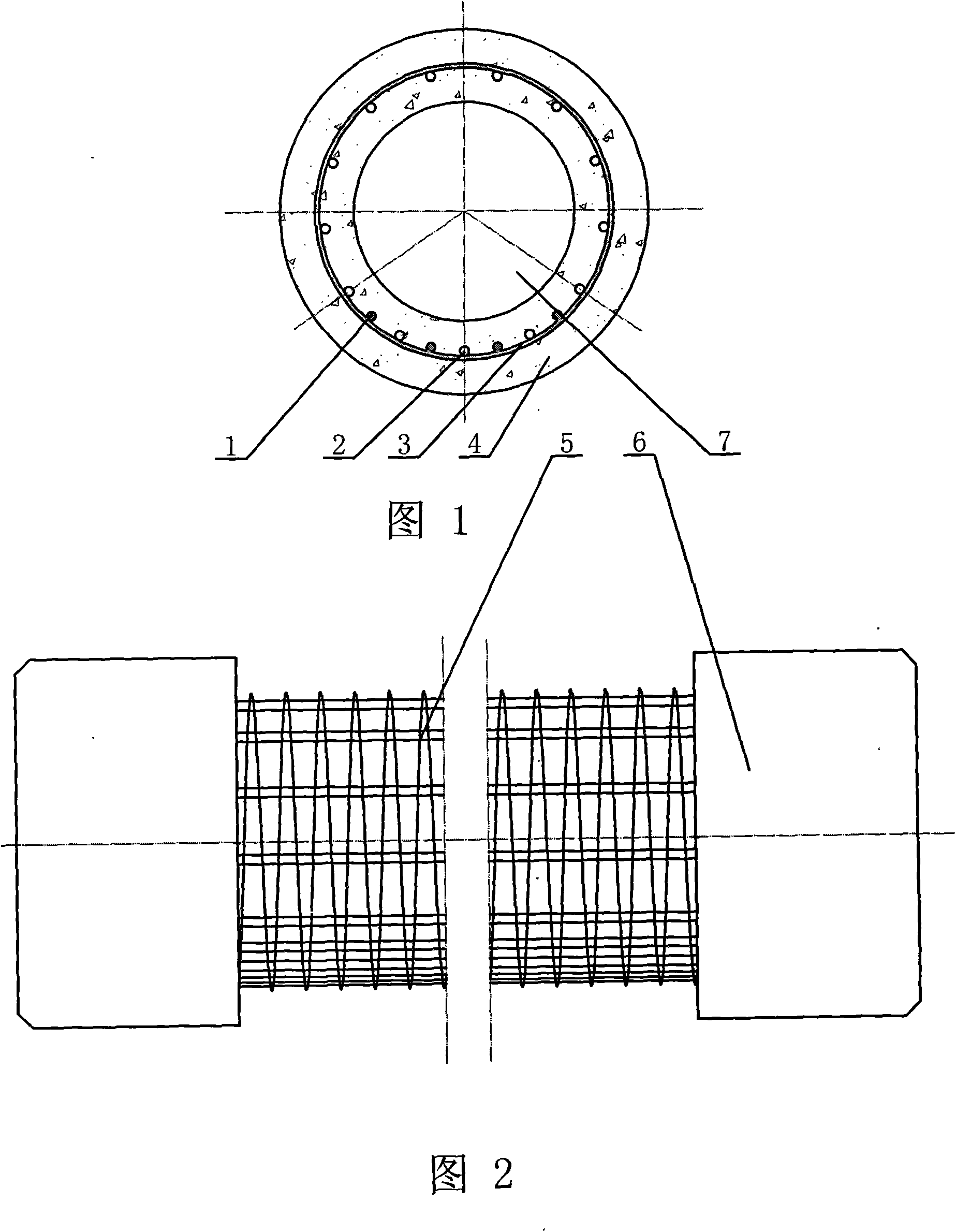

[0028] Such as figure 1 , 2 As shown, the pile type of this embodiment is ¢500X100, the traditional formula can be used to design the concrete 4 with a strength grade of C60, and the prestressed steel bars 2 can be thirteen high-strength prestressed concrete steel rods with a diameter of ¢10.7. It is 1570Mpa, and the non-prestressed steel bar 1 can adopt four HRB335 rebars with a diameter of ¢12.

[0029] First, the prestressed steel bar 2, non-prestressed steel bar 1, and spiral bar 3 are fixed in length, cut and blanked, and then the prestressed steel bar 2 is headed, and the wire is cold drawn into a cold drawn wire; the prestressed steel bar 2 and the spiral bar 3 are roll-welded into a Steel cage, and then the non-prestressed steel bars 1 are longitudinally bound and evenly distributed on the inner side of the spiral bars 3 in the tensile area 7 of the pipe pile section to make a steel bar skeleton cage 5; after making the end plate 6, the steel bar skeleton cage 5 and ...

Embodiment 2

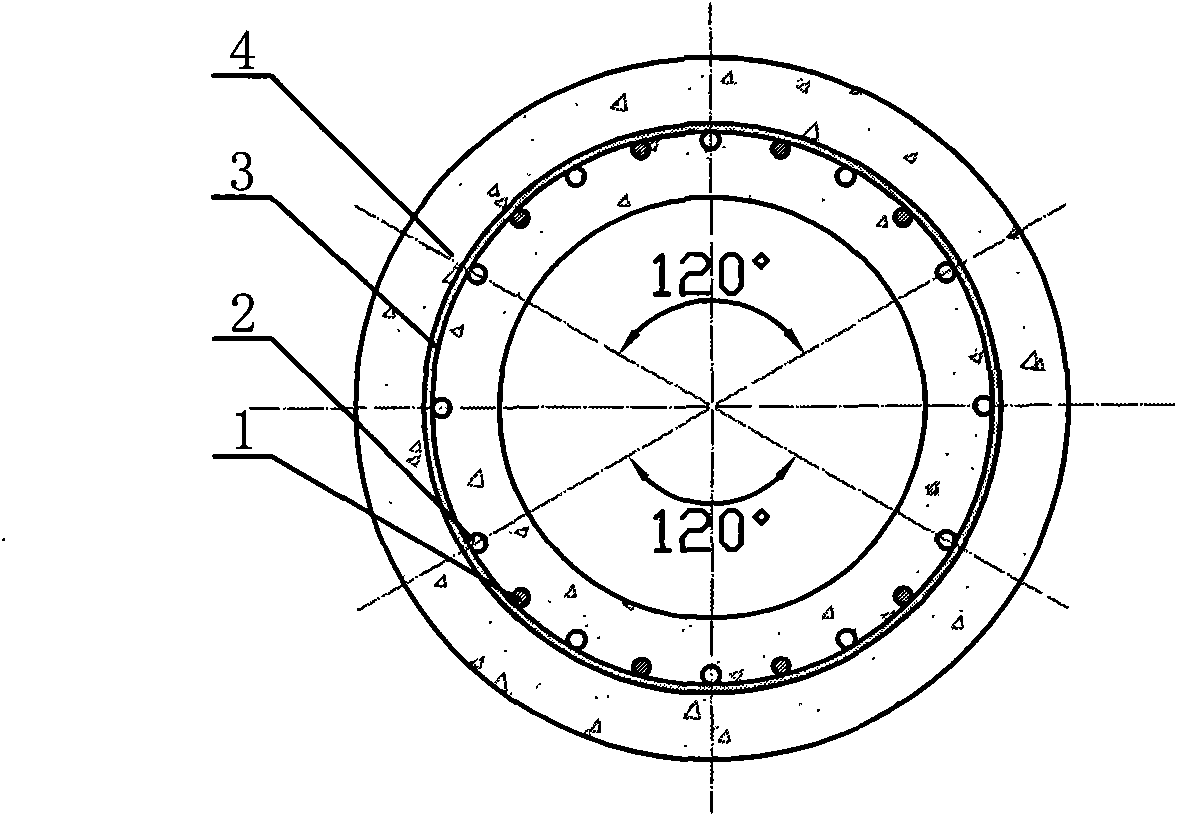

[0032] Such as image 3 Shown, repeat embodiment 1, have following difference: prestressed reinforcing bar 2 can adopt twelve high-strength prestressed concrete steel bars that diameter is ¢ 10.7, and its tensile strength is 1570Mpa, and non-prestressed reinforcing bar 1 can adopt eight HRB335 threaded steel with a root diameter of ¢12, non-prestressed steel bars 1 are bound longitudinally and evenly distributed on the inside of spiral bars 3 in two symmetrical fan-shaped tension areas with an included angle of 120 degrees on the pipe pile section.

Embodiment 3

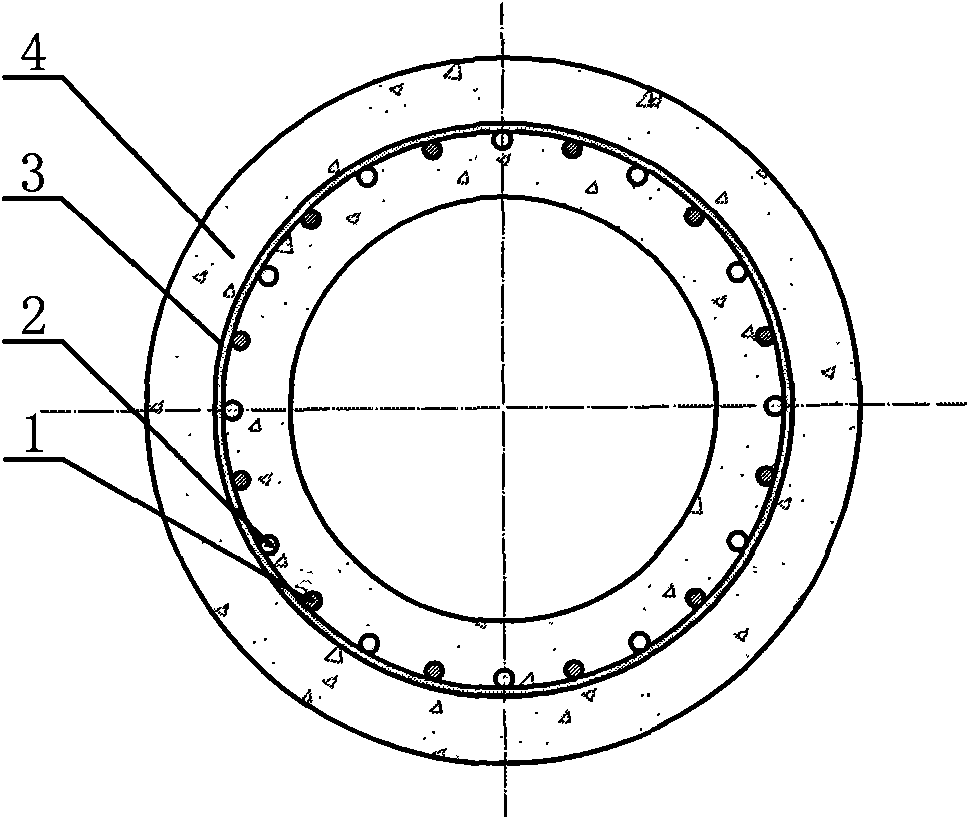

[0034] Such as Figure 4 Shown, repeat embodiment 1, following difference is arranged: prestressed reinforcing bar 2 can adopt twelve high-strength prestressed concrete steel bars that diameter is ¢ 10.7, and its tensile strength is 1570Mpa, and non-prestressed reinforcing bar 1 can adopt ten Two HRB335 rebars with a diameter of ¢12, the non-prestressed steel bar 1 is bound longitudinally and evenly distributed in the inner side of the spiral bar 3 in a circular shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com