Pretensioning prestressed concrete pile, stretch-draw anchoring piece thereof and method for manufacturing stretch-draw anchoring piece

A technology for concrete piles and a manufacturing method, which is applied in the directions of manufacturing tools, sheet pile walls, reinforcing molding, etc., can solve the problems of low production efficiency, waste of raw materials, and labor intensity of easily corroded workers, so as to improve quality, save materials, and reduce labor. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

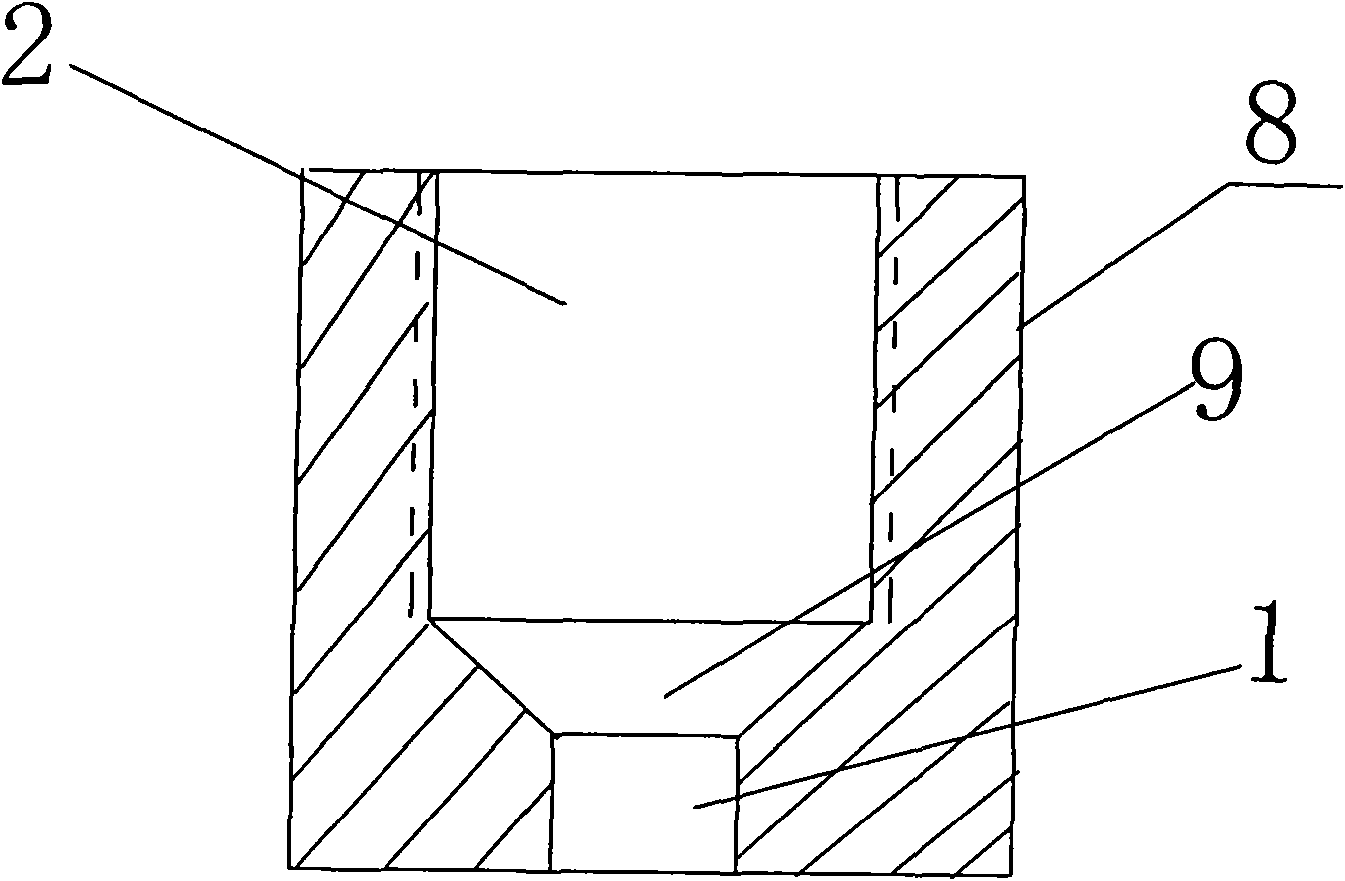

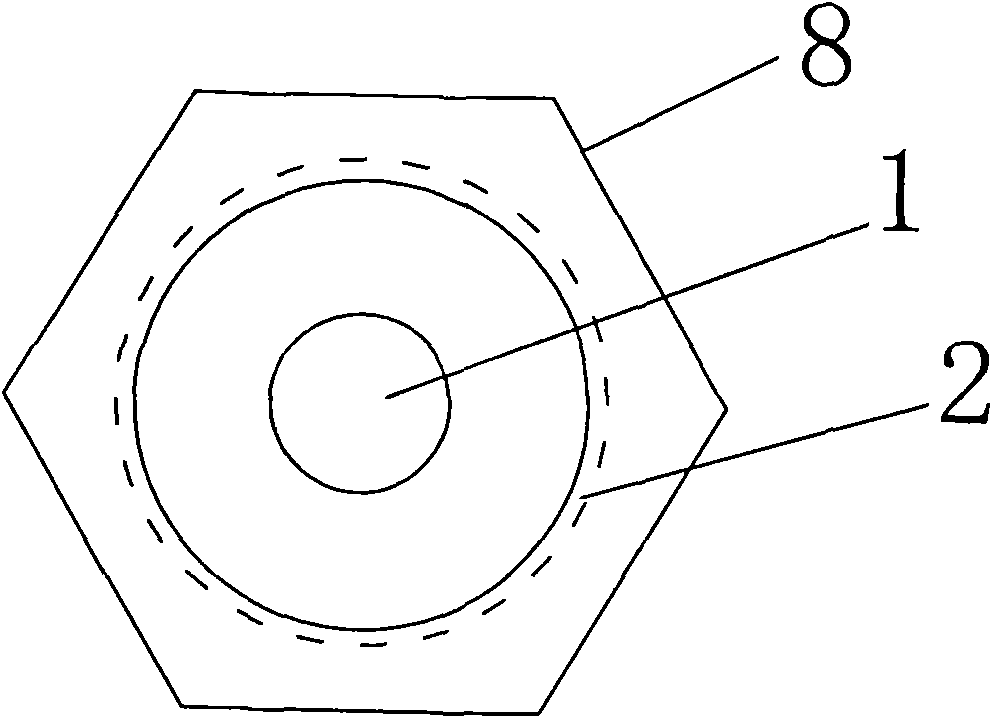

[0038] Such as figure 1 , 2 shown.

[0039] A tension anchor for pre-tensioned prestressed concrete piles, comprising a stainless steel body 8, the body 8 is provided with interpenetrating screw holes 2, countersunk holes 1, and connecting screw holes 2 and countersunk holes 1 Transition hole 9, the diameter of the sinking reinforcement hole 1 matches the diameter of the prestressed main reinforcement, the aperture of the screw hole 2 is larger than the aperture of the sinking reinforcement hole 1, and the described sinking reinforcement hole 1 is a cylindrical hole or a polygonal column hole. In order to prevent the main body 8 from losing its effect under the force rotation in concrete during specific implementation, so the end face profile of the main body 8 can be designed into a polygon (such as triangle, quadrangle, pentagon, hexagon, heptagon, octagon, nine sides) shape,...etc.), it can also be designed as a columnar anti-rotation structure consisting of at least one ...

Embodiment 2

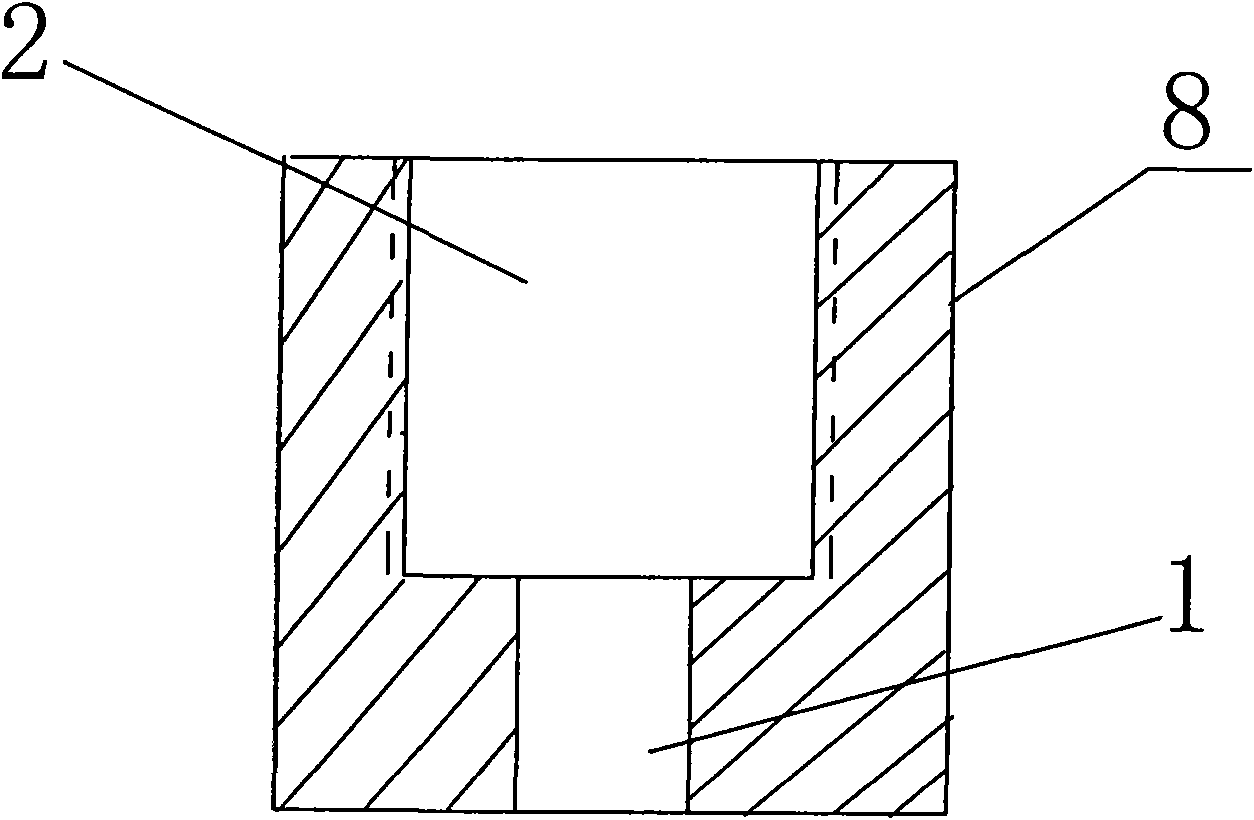

[0041] Such as image 3 shown.

[0042] The difference between this embodiment and Embodiment 1 is that the screw hole 2 directly communicates with the columnar countersunk hole 1 where the main steel bar is worn, and the step surface at the bottom of the screw hole is offset against the heading of the main steel bar so as to prevent the main steel bar from coming out of the body 8. fall off.

Embodiment 3

[0044] Such as Figure 4 shown.

[0045] The difference between this embodiment and Embodiment 1 is that the screw hole 2 directly connects with the tapered countersunk hole of the main steel bar, and the upset head of the main steel bar directly offsets the conical surface of the countersunk hole of the cone. The size of the head is larger than the size of the small end of the tapered countersunk hole, so it can also play a role in preventing the body from falling off the main steel bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com