Movable reinforcement cage binding jig

A steel cage and mobile technology, applied in water conservancy projects, reinforced molding, artificial islands, etc., can solve the problems of long construction period, inconvenient construction, affecting binding efficiency, and the convenience of precision installation and disassembly, so as to achieve convenient movement and improve The effect of ergonomics and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

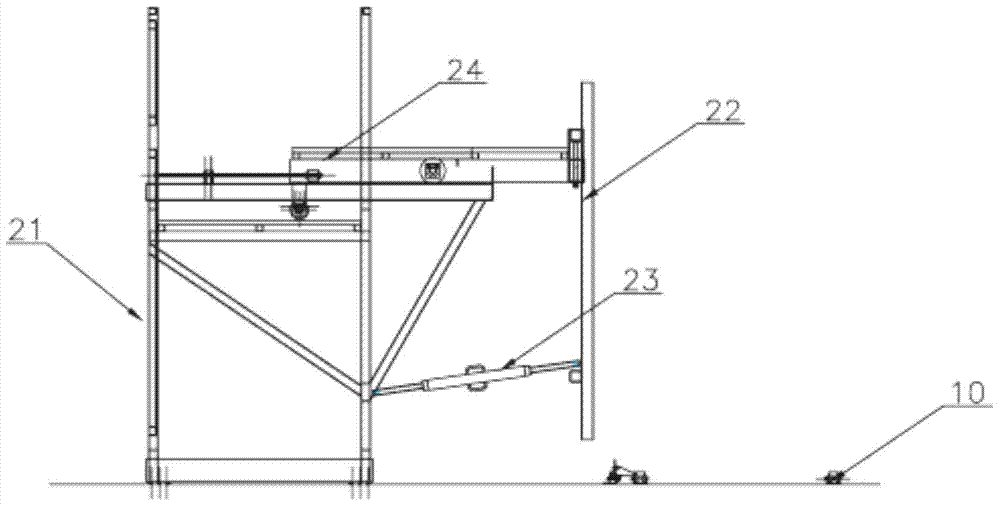

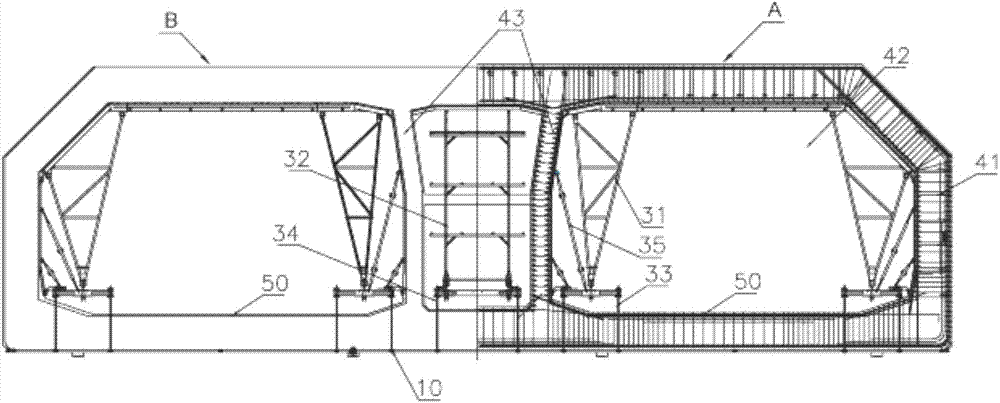

[0023] Such as figure 1 and figure 2 shown, (where, figure 2 The first support frame is not shown in, and figure 2 The center is divided into two areas, A and B, the area of A is the structure bound with the steel cage, and the structure not bound with the steel cage in the area B), a kind of movable steel cage binding tire frame of the present invention, it comprises sliding Rail 10, outer tire frame and inner tire frame, described slide rail is a plurality of parallel setting, wherein, outer tire frame is fixedly arranged on the outside of reinforcement cage, and inner tire is erected in the inside of reinforcement cage and is positioned on slide rail 10. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com