Pipe pile automatic production line

An automated production line and pipe pile technology, applied in sheet pile walls, reinforced molding, ceramic molding workshops, etc., to reduce potential safety hazards, improve operating efficiency, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention:

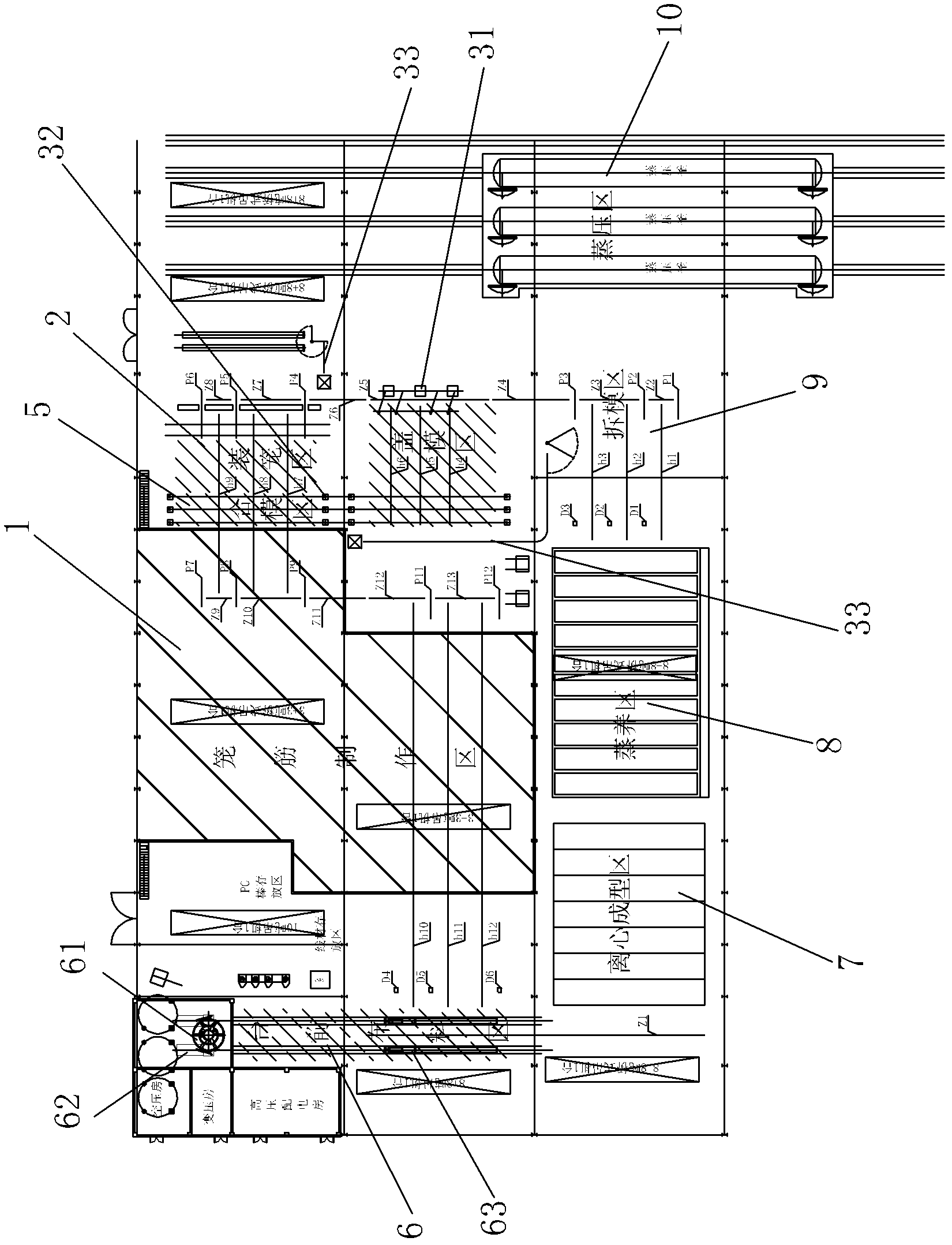

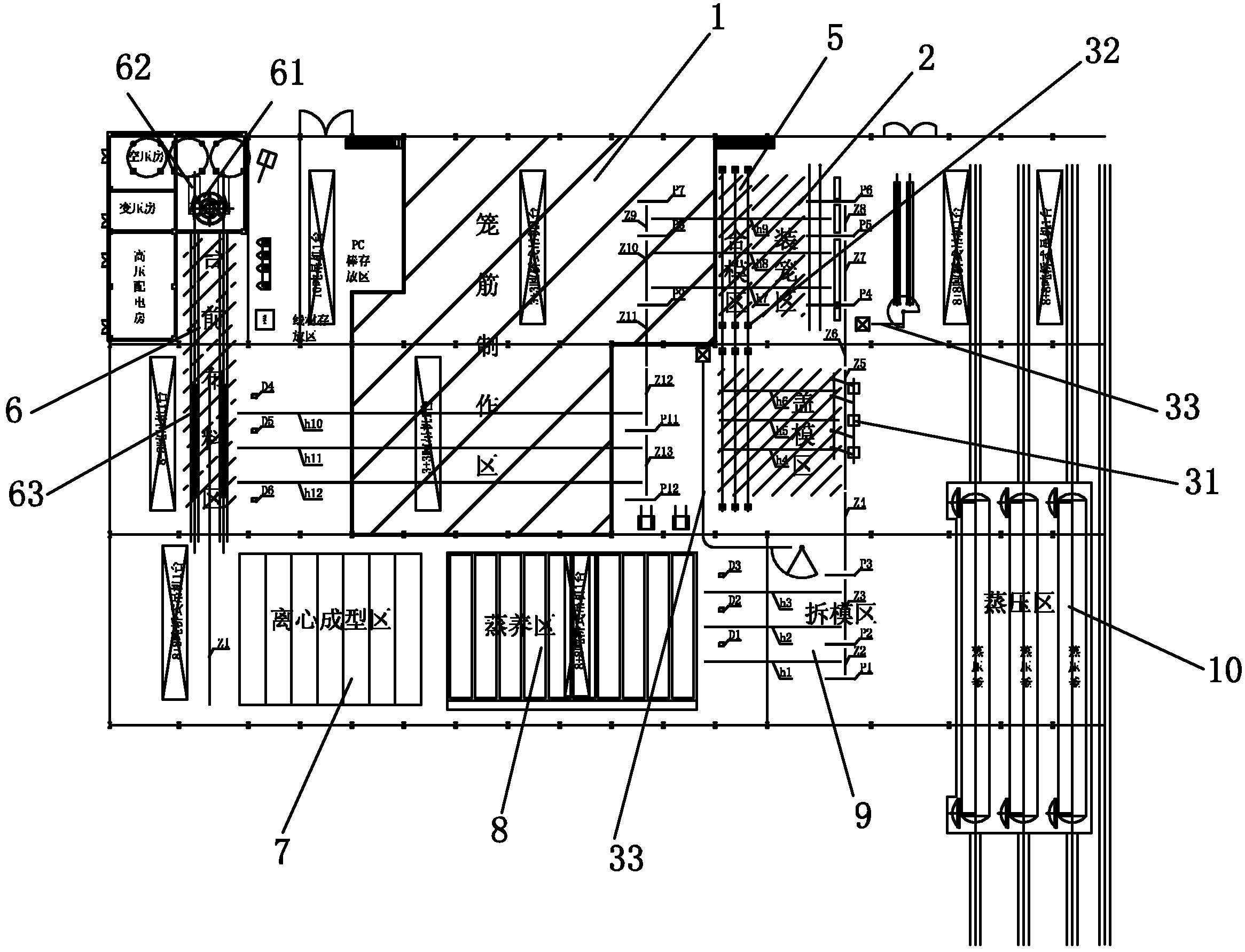

[0045] Such as figure 1 As shown, the automated production line for pipe piles includes:

[0046] Cage bar production area 1 for making cage bars and assembling the head plate, tail plate, and cage bars together;

[0047] It is arranged on one side of the cage bar production area 1, and is used to assemble the cage bar made into the cage loading area 2 on the bottom mold; the cage bar production area 1 and the cage loading area 2 are provided There is a pipe mold conveying unit 3;

[0048] It is arranged on one side of the cage area 2, and the cover mold area (4) for cleaning and transporting the cover mold after the cover mold is uncovered;

[0049] Set between the cage loading area 2 and the cage bar manufacturing area 1, the mold clamping area 5 for clamping the mold after the cover mold is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com