Manufacturing process of pre-tensioned prestressed centrifugal concrete square pile

A production process and concrete technology, which is applied in the field of production process of pre-tensioned prestressed centrifugal concrete square piles, can solve the problems of high foundation cost, long concrete natural curing time, long production cycle, etc. The effect of short maintenance time and reduced engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

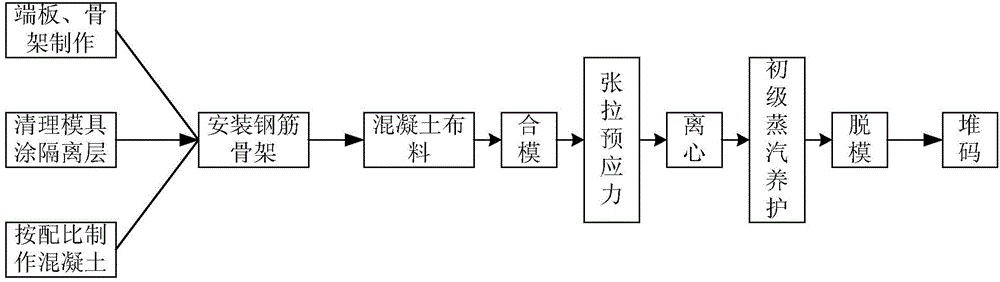

[0029] Such as figure 1 Shown, a kind of manufacturing technology of pretensioned prestressed centrifugal concrete square pile comprises the following steps:

[0030] a. Measuring and mixing of concrete raw materials: accurately measure sand, stone, cement, water, admixtures, and admixtures according to the mix ratio, and use a concrete forced mixer to make fresh concrete with a low slump of 3 to 5 cm; design The strength grade of concrete is required to be not lower than C60.

[0031] b. Manufacturing of centrifugal square pile end plate: It is basically the same as that of pipe pile end plate, but the shape of centrifugal square pile end plate is made into a square shape, and counterbores for prestressed main reinforcement are set at the four corners of the end plate. Before the square end plate is installed, square pile hoops made of thin steel plates with a thickness of 1.5-2 mm need to be welded around.

[0032] c Skeleton production: Prestressed main reinforcement and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com