A kind of production method of concrete pile without autoclaving and pouring residual slurry

A technology of concrete piles and production methods, applied in the direction of strengthening molding, etc., can solve the problems of high pH value, difficult handling, high management requirements, etc., and achieve the effects of improving durability, reducing investment costs, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

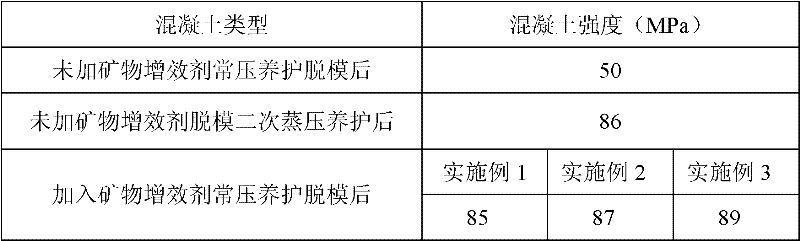

Examples

Embodiment 1

[0024] To produce PHC pipe piles, the concrete mix ratio is composed of a mixture of cement and mineral powder, sand, gravel, high-efficiency water reducer, mineral synergist and water, wherein the water-cement ratio is 0.3, and the specific surface area of the cementitious material is 420kg / m 3 The fineness modulus of the sand is 2.5, and the sand rate is 30%; the particle size of the gravel is 5mm-25mm, and the crushing value is 5%; 0.7%; wherein said mineral synergist, its dosage is 10% of cementitious material, and described mineral synergist is made of 50% finely ground gypsum and 50% microsilica;

[0025] production process:

[0026] First put sand, cementitious material, and mineral booster into the concrete mixer and stir until uniform, then in turn the required water reducer and 75% of the water in the entire formula, and then stir until uniform, and finally put in crushed stone and The remaining 25% of water is then stirred until uniform;

[0027] Evenly put the...

Embodiment 2

[0032] To produce PHC pipe piles, the concrete mix ratio is composed of a mixture of cement and mineral powder, sand, gravel, high-efficiency water reducer, mineral synergist and water, wherein the water-cement ratio is 0.2, and the specific surface area of the cementitious material is 300kg / m 3 ; The fineness modulus of the sand is 2.0, and the sand rate is 27%; the particle size of the crushed stone is 5mm-25mm, and the crushing value is 5%; 3% of the total cementitious material; wherein said mineral synergist is 10% of the cementitious material, and said mineral synergist consists of 80% ground gypsum and 20% microbeads;

[0033] production process:

[0034] First put sand, cementitious material, and mineral booster into the concrete mixer and stir until uniform, then in turn the required water reducer and 75% of the water in the entire formula, and then stir until uniform, and finally put in crushed stone and The remaining 25% of water is then stirred until uniform;

...

Embodiment 3

[0040] To produce PHC pipe piles, the concrete mix ratio is composed of a mixture of cement and mineral powder, sand, gravel, high-efficiency water reducer, mineral synergist and water, wherein the water-cement ratio is 0.4, and the specific surface area of the cementitious material 450kg / m 3 The fineness modulus of the sand is 3.5, and the sand rate is 44%; the particle size of the gravel is 5mm-25mm, and the crushing value is 5%; 1.5%; wherein said mineral synergist its dosage is 10% of the cementitious material, and said mineral synergist consists of 40% ground gypsum and 60% microbeads;

[0041] production process:

[0042] First put sand, cementitious material, and mineral booster into the concrete mixer and stir until uniform, then in turn the required water reducer and 75% of the water in the entire formula, and then stir until uniform, and finally put in crushed stone and The remaining 25% of water is then stirred until uniform;

[0043] Evenly put the pre-mixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com