Insulated standard and processing technique thereof

A processing technology and technology for utility poles, applied in the field of utility poles, can solve the problems of easy aging, short service life, poor insulation, etc., and achieve high insulation performance, cost reduction, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

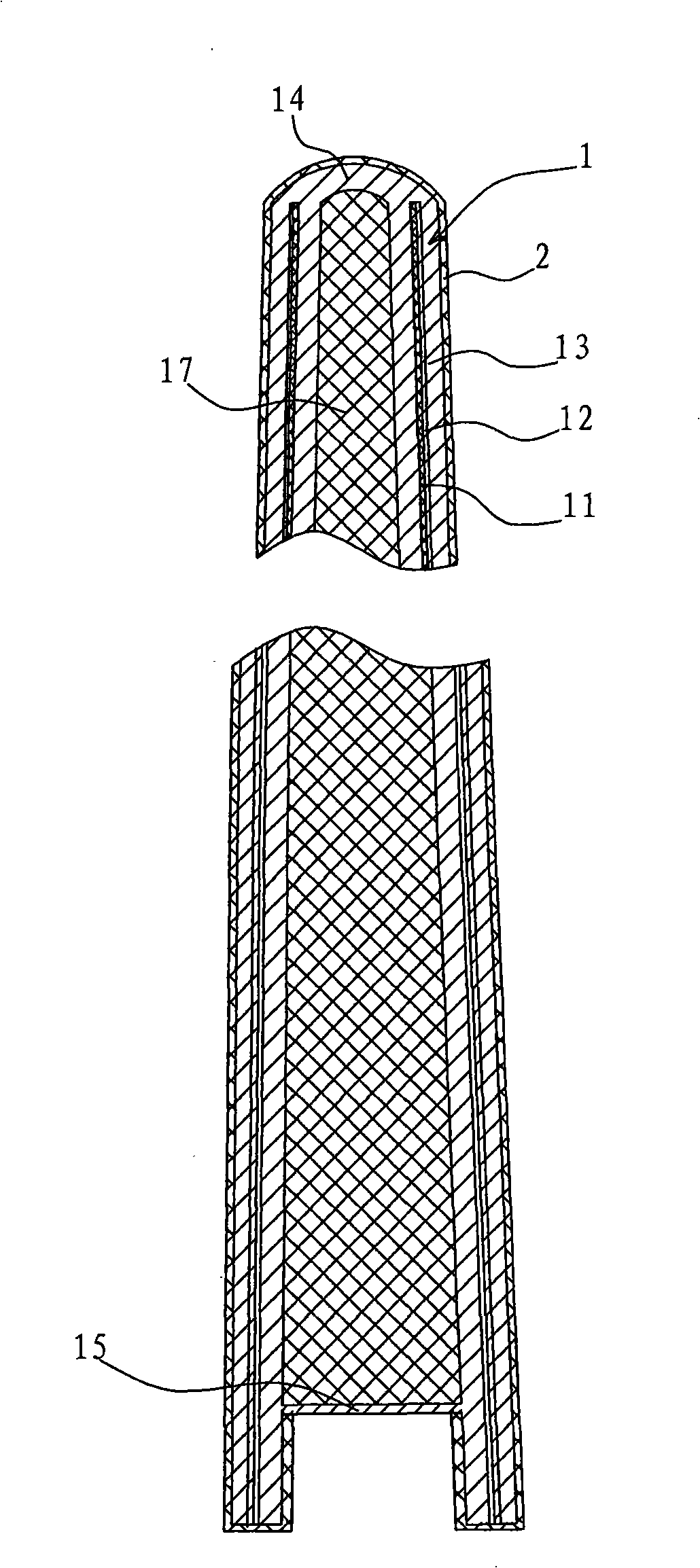

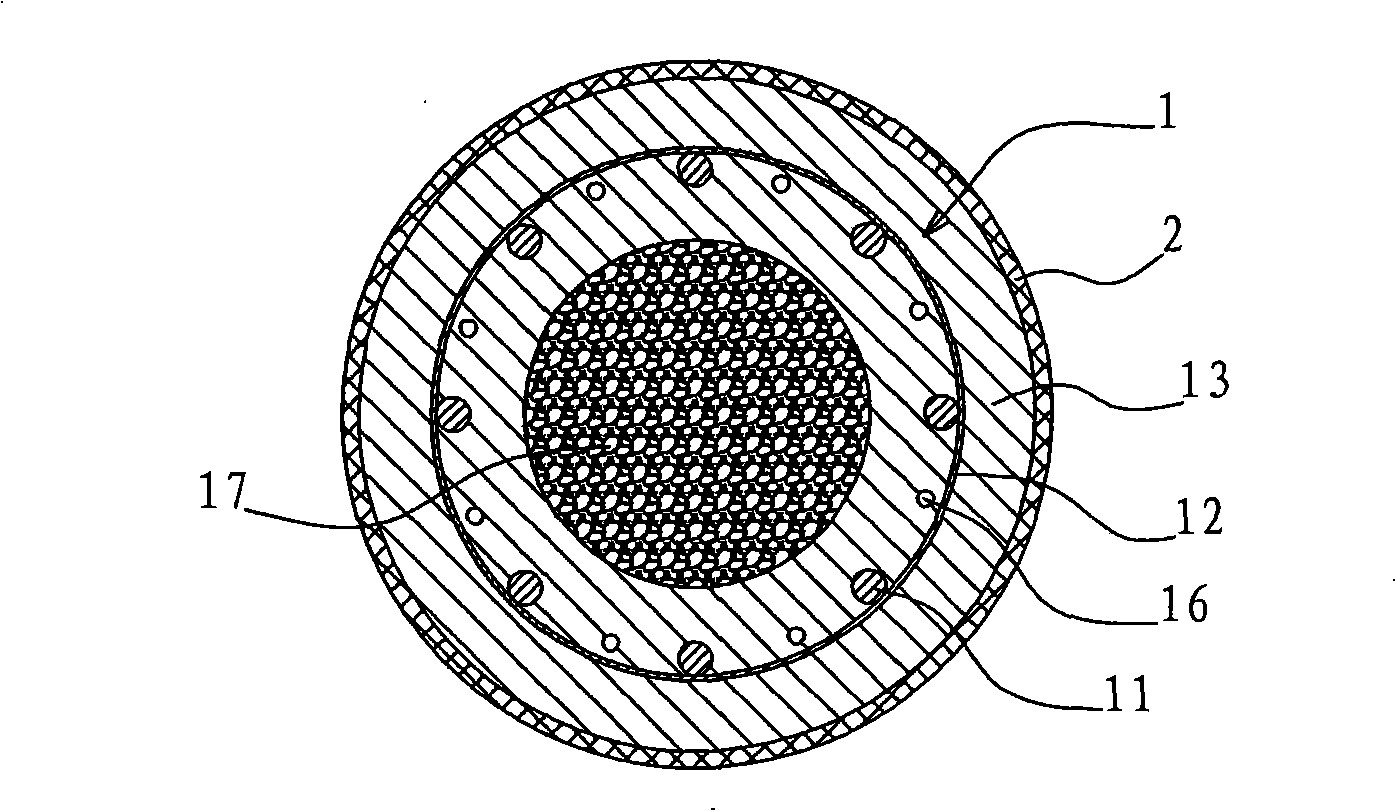

[0036] see figure 1 , figure 2 and image 3 , a preferred embodiment of an insulated utility pole provided in the present invention includes a main body layer 1 and a surface layer 2 coated on the main body layer 1, and the surface layer 2 is a combination of organic matter and inorganic matter The functional waterproof layer formed, the main body layer 1 includes a plurality of insulating glass fiber reinforced plastic main bars 11, at least one layer of insulating grid glass fiber cloth 12 wrapped around a plurality of the main bars 1 and wrapping the main bars 11 and insulating grid glass fibers The fiber reinforced cement 13 of the cloth 12, the top end 14 and the lower end 15 of the main body layer 1 are closed, and coated with a functional waterproof layer formed by combining organic matter and inorganic matter.

[0037] The waterproof layer in the present invention is a modified cement formed by combining fluoropolymer and cement, wherein the fluoropolymer is an orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com