Novel highly-efficiency, energy-saving and environmentally-friendly method and system for manufacturing centrifugal concrete pile

A technology of concrete piles and manufacturing methods, which is applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of high cost, weak load-bearing capacity, and inconformity with national industrial development policies, etc., and achieve low cost and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

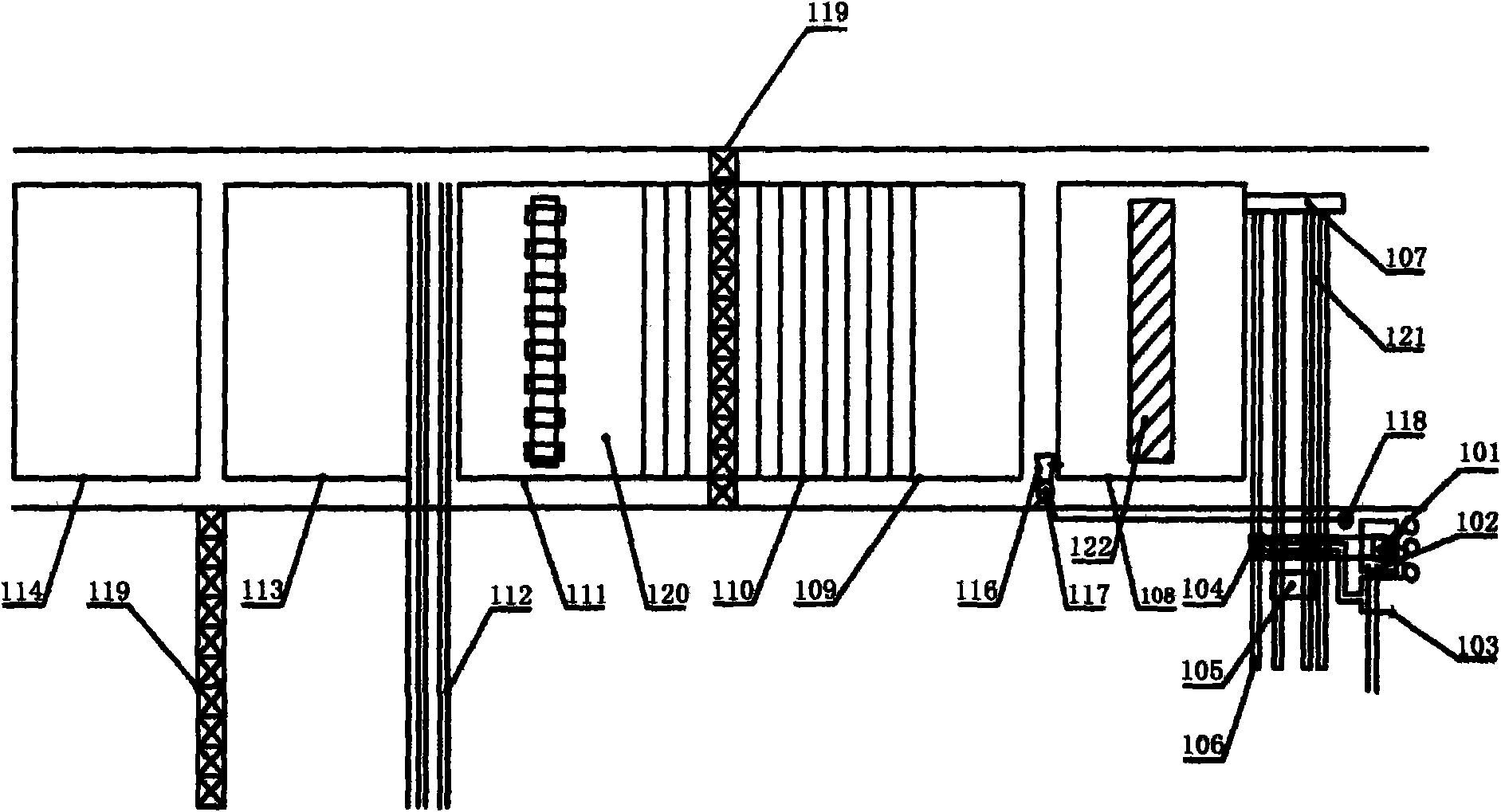

[0061] Please refer to the accompanying drawings to illustrate its implementation process:

[0062] Such as figure 1 As shown, the overall structural diagram of the manufacturing system of the novel high-efficiency, energy-saving, and environment-friendly centrifugal concrete piles of the present invention, the system includes a control room 105 and a steel cage processing area 114 connected in sequence, a piling driveway 112, a form removal area 111, and an upper mold Cleaning area 109, centrifugal area 108, tensioning area 107, mold clamping area 121, described tensioning area 107 is connected with feeding channel 106, feeding channel 106 is connected with feeding hopper 104, feeding hopper 104, ferry car 101 and mixer 102 It is sequentially connected with the waste water pool 103, and a residual slurry recovery device is arranged between the centrifugal area 108 and the mixer 102, and also includes a lifting machine equipment 119 in the workshop, and the manufacture of cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com