Offshore wind power unit foundation adopting prestressed concrete cylindrical structure

A cylindrical foundation and offshore wind power technology, applied in infrastructure engineering, construction, etc., can solve the problem of increased foundation investment costs for offshore wind turbines, increased foundation costs for offshore wind turbines, and the absence of fully prestressed concrete cylindrical foundations, etc. problems, to achieve the effect of reducing the difficulty of production, saving materials, and reducing the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

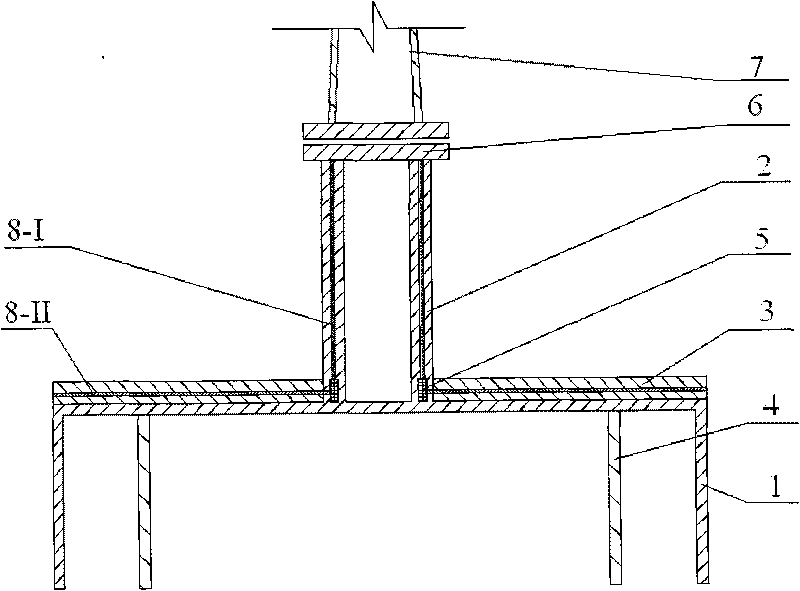

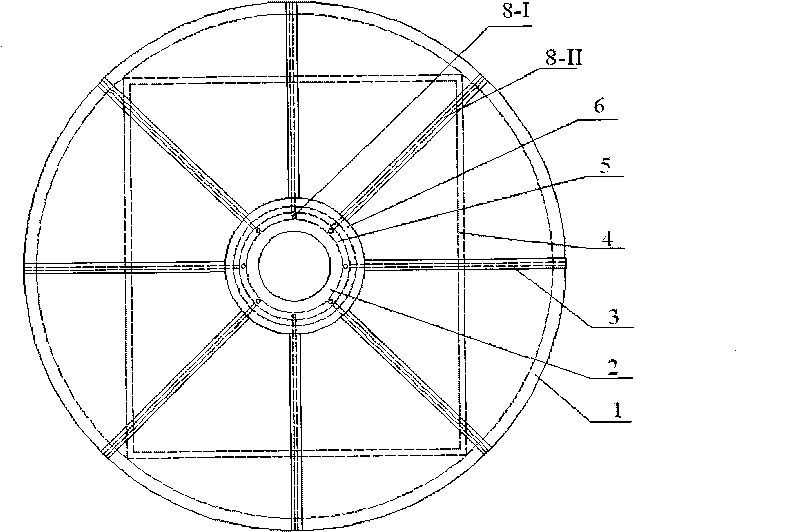

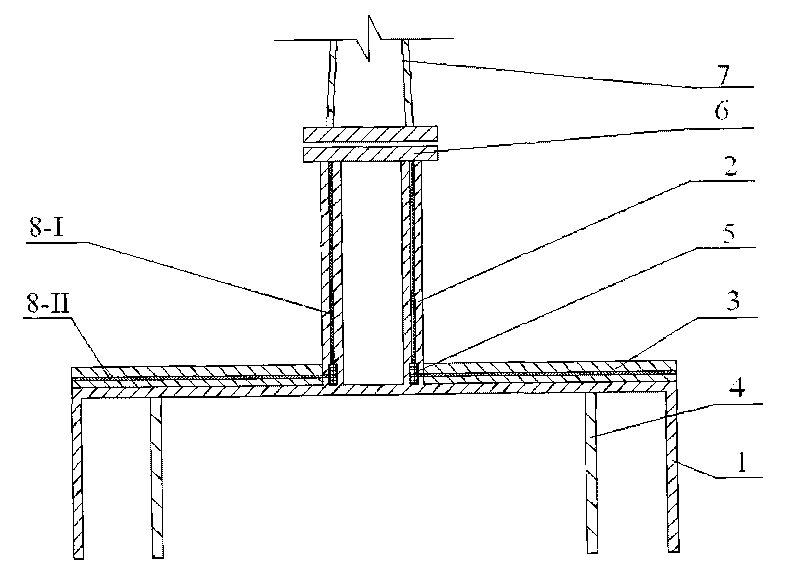

[0016] A prestressed concrete cylindrical structure foundation foundation for offshore wind turbines, consisting of a cylindrical foundation 1, a prestressed beam 3 and a connecting tower 2, the cylindrical foundation 1 is a reinforced concrete cylindrical structure with a sealed roof, The interior of the cylindrical foundation 1 is provided with partitions 4. The partitions 4 are fixed on the inner wall of the cylindrical foundation 1 with steel plates in a regular quadrilateral shape, and divide the cavity of the cylindrical foundation 1 into a middle chamber and four side chambers. ; The prestressed beam 3 is a concrete structure, and there are eight prestressed concrete beams, which are arranged on the sealed top cover of the cylindrical foundation 1 and are radially evenly distributed; the connecting tower 2 is a prestressed concrete cylindrical structure, and its lower end It is integrated with the reinforced concrete cylindrical foundation 1 and the prestressed beam 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com