Precast assembly process of prestressed concrete cylindrical hollow pier

A prefabricated and prestressed technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of low construction efficiency, unfavorable quality control, long construction period, etc., and achieve the effect of improving construction efficiency, shortening construction period and reducing self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the drawings and embodiments.

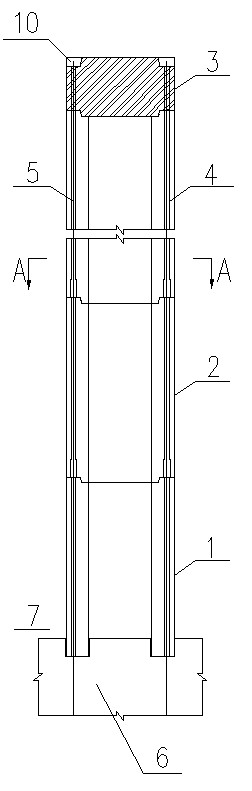

[0032] see Figure 1 to Figure 5 , a prefabricated assembly process of prestressed concrete cylindrical hollow pier, comprising the following steps in sequence:

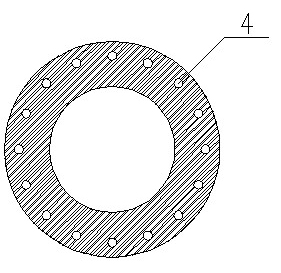

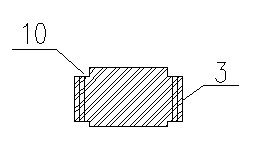

[0033] 1. Prepare prefabricated components: Hollow piers with a circular cross-section: including transition section 1 and standard section 2, wherein one end of the transition section 1 is provided with an installation step 8, and both ends of the standard section 2 are provided with installation steps 8; A solid pier top section 3, the lower end of the pier top section 3 is provided with an installation step that can be nested and matched with the installation step on the standard section 2, and an annular prestressed tension anchoring construction groove 10 is provided on the outer ring of the upper end;

[0034] The annular wall of said hollow pier column is longitudinally provided with a reserved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com