Prestressed concrete pipe pile with pretensioning type strands

A technology of concrete pipe piles and concrete piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems affecting the construction quality and service life of buildings, reducing the mechanical performance index of steel rods, and the strength cannot meet quality requirements, etc. problems, to achieve the effect of large prestress, high bending strength and high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

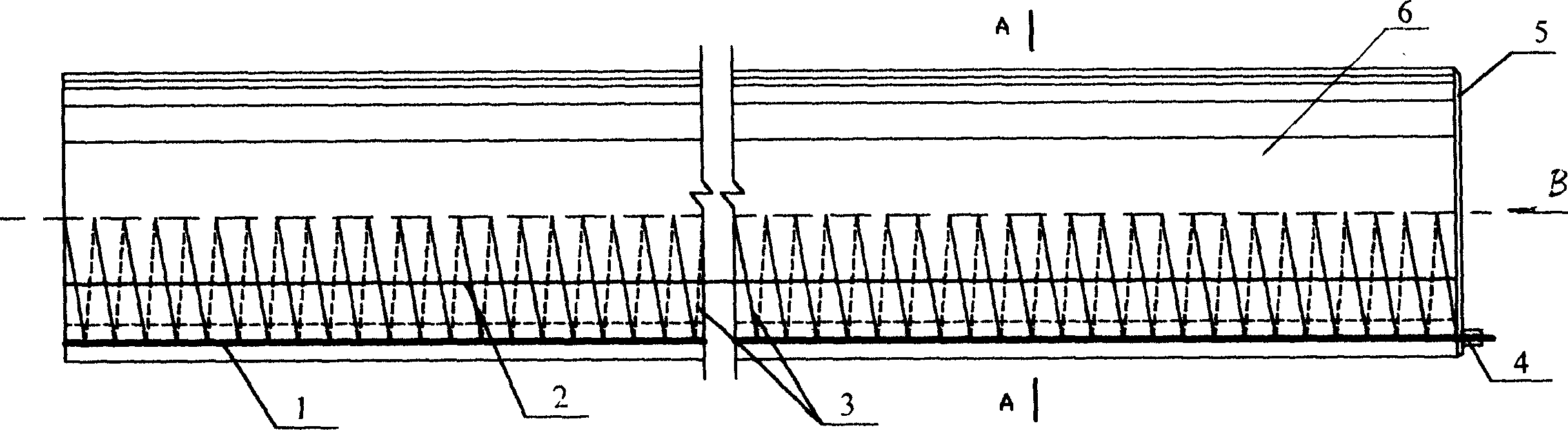

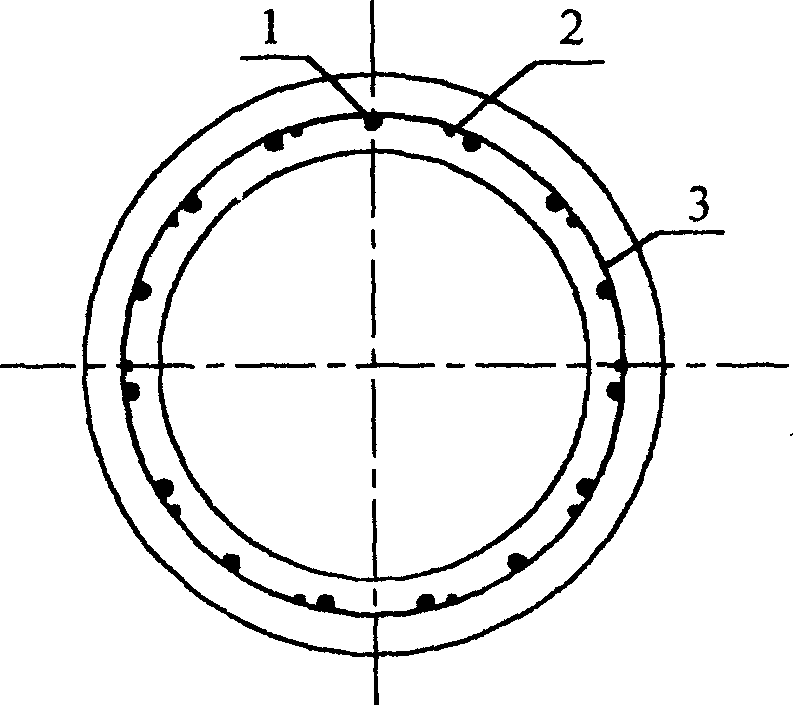

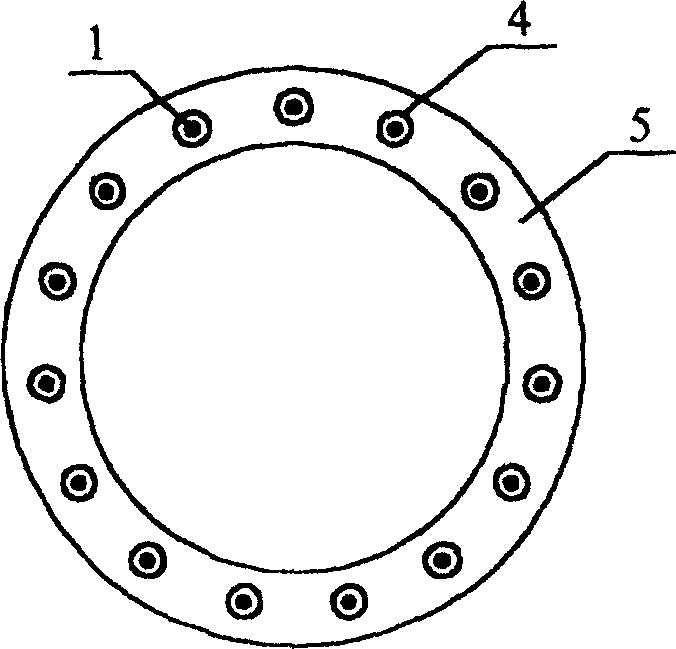

[0009] As shown in the figure, the steel hinge line prestressed concrete pipe pile is composed of an annular tubular concrete pile body 6 and an end plate 5 . The end plate 5 covers the end of the pile body 6 . The pile body of the concrete pipe pile is built with a steel skeleton. The prestressed main reinforcement 1 of the steel skeleton is a steel hinge line. The spiral surrounds and fixes and connects each prestressed main reinforcement 1 and erecting reinforcement 2 to form a whole of the steel skeleton. The end plate 5 is provided with a stretching hole, and the prestressed main reinforcement passes through the stretching hole to make the prestressed anchor 4 . During manufacture, concrete can be poured on the reinforced skeleton first, then the prestressed main reinforcement can be stretched by closing the mold, and the tubular prestressed concrete pipe pile can be made through centrifugation and steam curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com