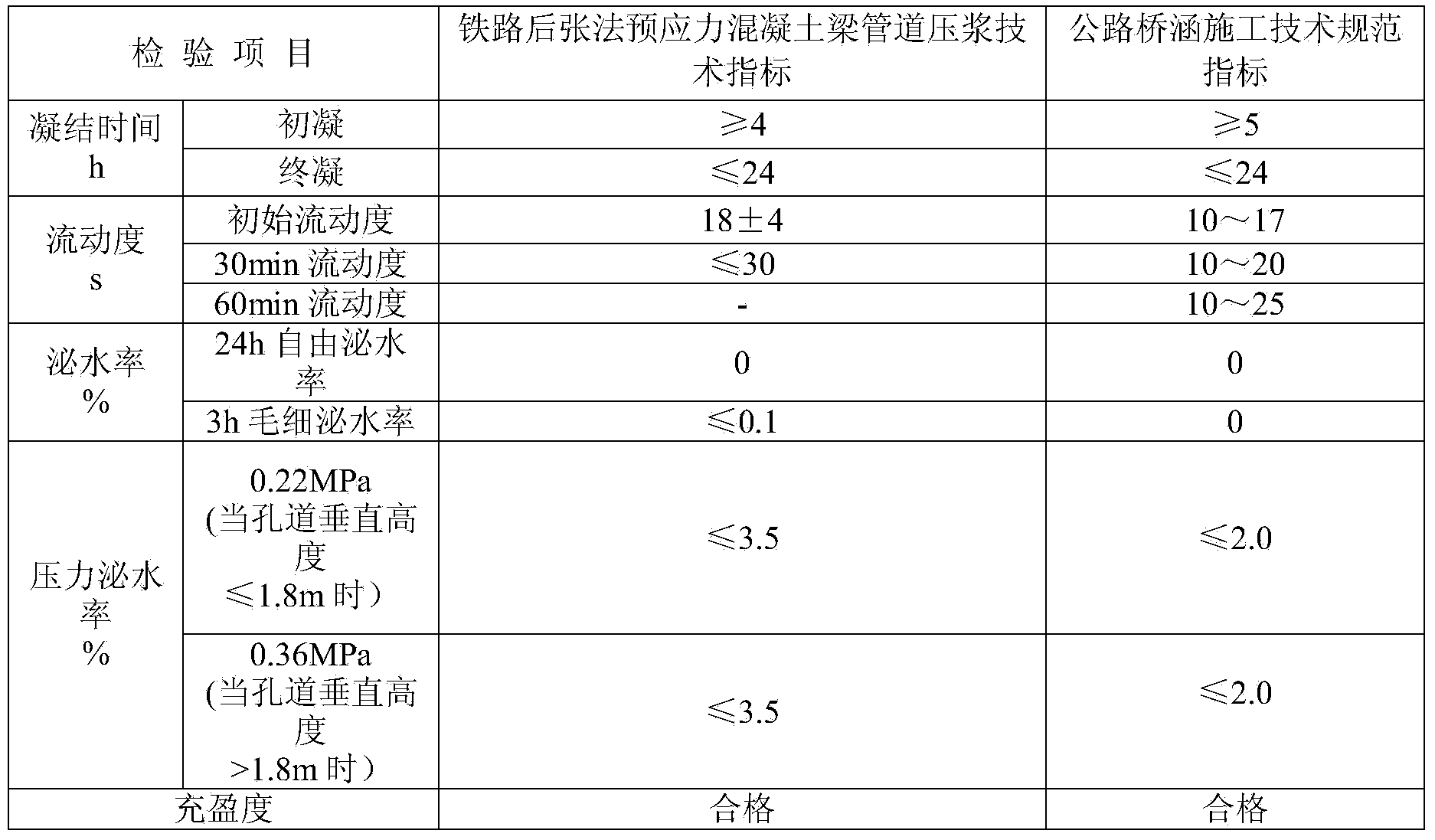

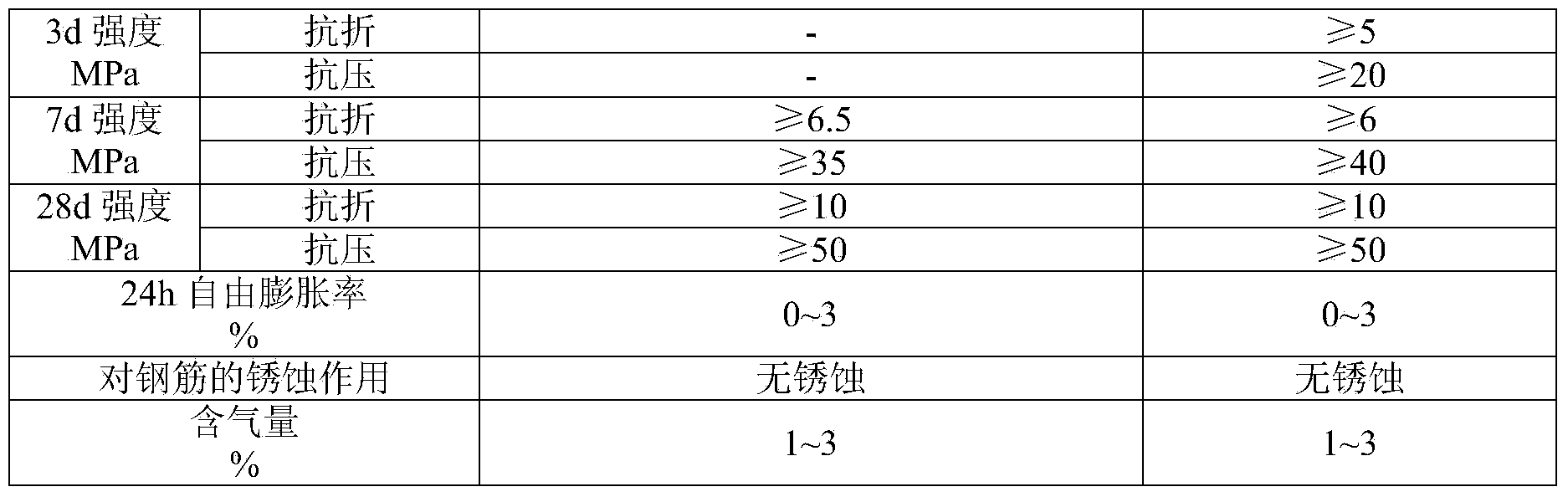

Upper-flow-regime micro-expanding post-tensioning prestressed porelike grouting agent and preparation method thereof

A post-tensioning prestressing and channel grouting technology, which is applied in the field of building materials, can solve problems such as difficulty in meeting new standards and poor adaptability of cement, and reduce the probability of segregation and stratification, cost economy, and increase The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

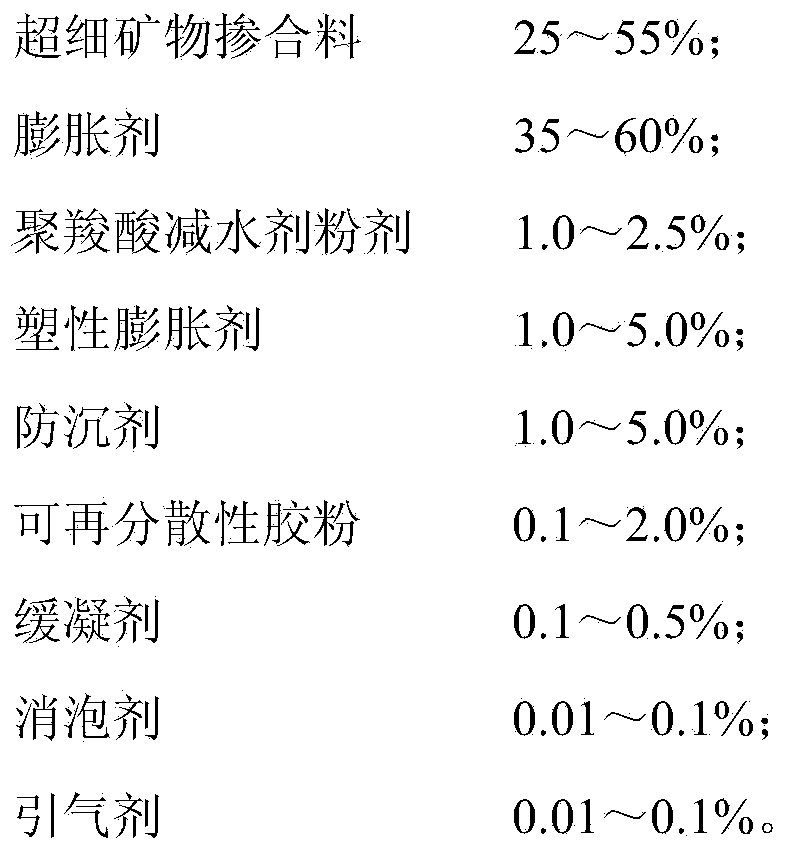

[0032] A high-water-reducing, high-fluidity micro-expansion highway bridge and culvert post-tensioning prestressed grouting agent, which is suitable for use in high-grade cement. It can be adjusted by adjusting the dosage in the range of 10-12%, without changing the change of small internal materials. To meet the needs of different projects, its components by weight percentage are:

[0033] S95 mineral powder: 13%;

[0034] Silica powder: 27%

[0035] AUA expansion agent: 52.5%;

[0036] GC polycarboxylate superplasticizer powder: 1.8%;

[0037] GQ polycarboxylate superplasticizer powder: 0.5%;

[0038] CSA plastic expansion agent: 2.0%;

[0039] Organic bentonite: 1.8%;

[0040] Vinyl acetate and ethylene copolymer powder: 1.1%;

[0041] Sodium gluconate: 0.2%;

[0042] Silicone defoamer: 0.06%;

[0043] Rosin resin air-entraining agent: 0.04%.

[0044] Among them, the specific surface area of S95 mineral powder is 497m 2 / kg. , the specific surface area of silic...

Embodiment 2

[0052] A function-adaptive high-fluid micro-expansion highway bridge and culvert post-tensioning prestressed channel grouting agent, which can ensure the relevant index parameters of the grouting agent under the condition of only adjusting the amount of pressure drop agent for the frequent replacement of cement varieties on site. Its components are by weight percentage:

[0053] Stone powder: 20%;

[0054] Silica powder: 15%

[0055] S75 mineral powder: 10%

[0056] CSA expansion agent: 47%;

[0057] GC polycarboxylate superplasticizer powder: 0.5%;

[0058] GQ polycarboxylate superplasticizer powder: 2.0%

[0059] CSA plastic expansion agent: 2.0%;

[0060] Castor oil derivatives: 2.0%;

[0061] Acrylate and styrene copolymer powder: 1.2%;

[0062] Sodium tripolyphosphate: 0.2%;

[0063] Distearyl ethylenediamine defoamer: 0.08%;

[0064] Rosin resin air-entraining agent: 0.02%.

[0065] Among them, the specific surface area of stone powder is 421m 2 / kg, the spe...

Embodiment 3

[0069] An ultra-plastic, high-fluid, micro-expansion post-tensioned prestressed channel grouting agent for road bridges and culverts. Aiming at the characteristics of slag-type cement that is easy to bleed and the hydration speed is relatively slow, it is adjusted from the type of water-reducing agent used and the internal components. , so that it meets the relevant standard indicators, and its components are by weight percentage:

[0070] Silica powder: 45%;

[0071] HEA expansion agent: 47%;

[0072] 010 polycarboxylate superplasticizer powder: 1.8%;

[0073] GQ polycarboxylate superplasticizer powder: 0.5%

[0074] ZYG-S plastic expansion agent: 2.5%;

[0075] Organic bentonite: 1.6%;

[0076] Polyacrylamide: 0.5%;

[0077] Styrene and butadiene copolymer powder: 0.8%;

[0078] Citric acid: 0.15%;

[0079] Organic fluoride defoamer: 0.05%;

[0080] Alkylbenzenesulfonate air-entraining agent: 0.1%.

[0081] Among them, the specific surface area of silica powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com