Full prestressed concrete integrated root solid square pile with steel pile tip and manufacturing method thereof

A processing method and prestressing technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex production process of concrete piles, high labor intensity, increased production cost of concrete piles, etc., and achieve remarkable effect of use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

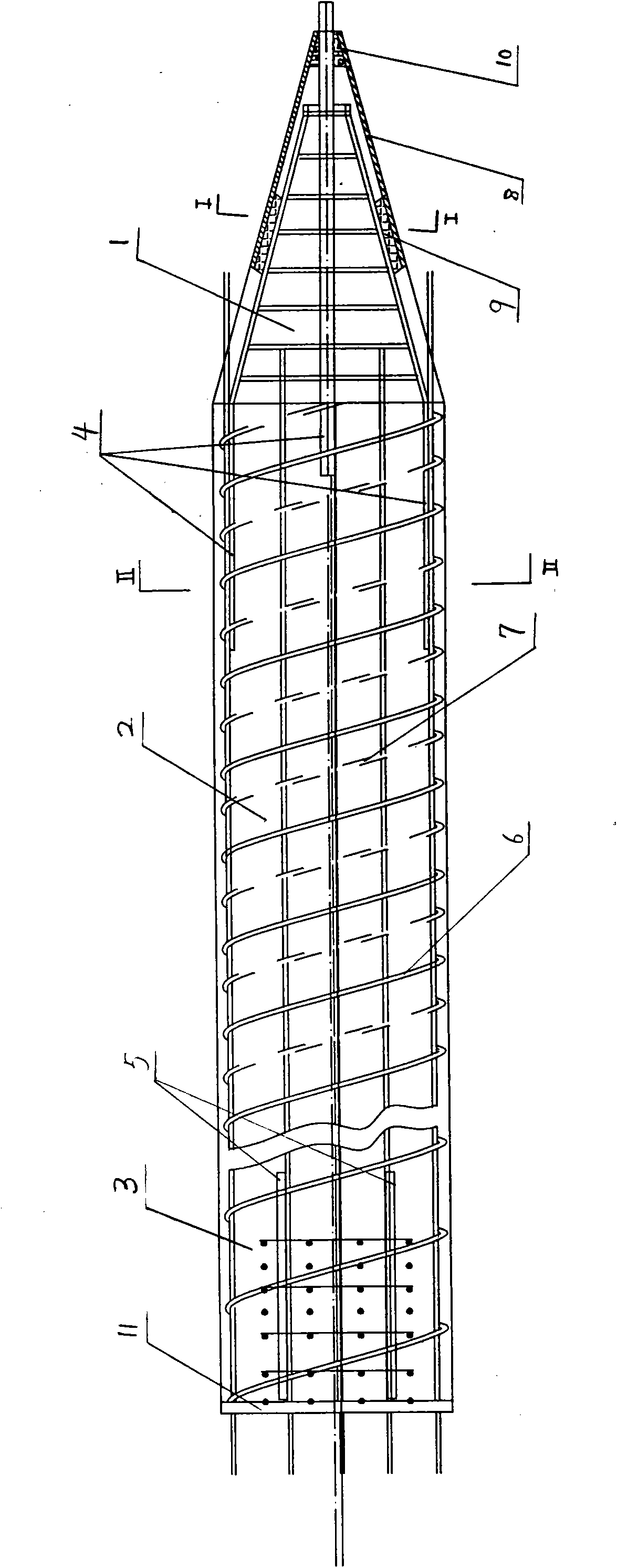

[0043] According to the needs of a certain project, a steel pile tip fully prestressed concrete whole solid square pile is designed and produced, with a cross section of 700×700 (mm), a length of 25 meters, and a total of 16 prestressed main reinforcements with a diameter of 12.6. mm, the stirrup diameter is 8mm.

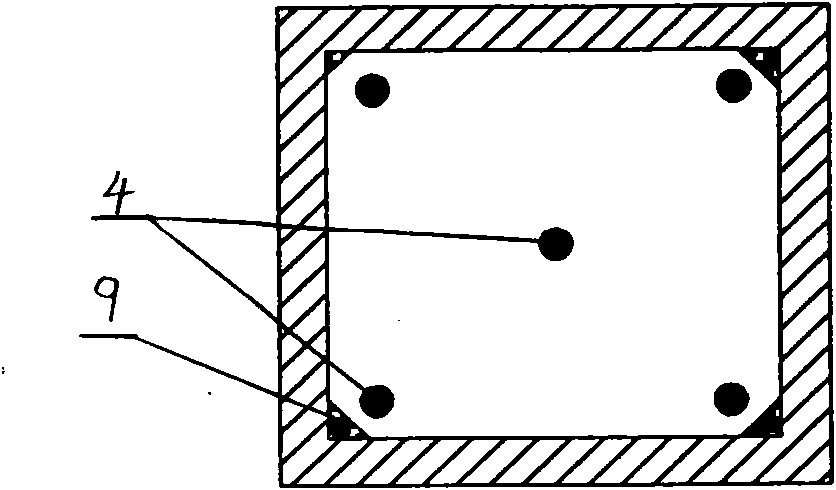

[0044] Such as figure 1 As shown, the whole solid square pile of fully prestressed concrete at the tip of the steel pile includes a pile tip 1, a pile body 2, and a pile cap 3; The pile tip 1 is inserted into the pile body 2 through the pile tip anchor bar 4, and the pile tip anchor bar 4 is bound and connected to the intersection of the stirrup bar; the pile cap 3 is inserted into the pile body 2 through the pile cap anchor bar 5, and the pile cap anchor bar 5 is connected to the stirrup bar The intersection is bound and connected; the steel pile tip is fully prestressed concrete, and the whole solid square pile is made of concrete pouring.

[0045] The prestress...

Embodiment 2

[0050] According to the needs of a certain project, a steel pile point fully prestressed concrete whole solid square pile is designed and produced, with a cross section of 300×300 (mm), a length of 15 meters, and a total of 8 prestressed main reinforcements with a diameter of 7.1 mm, the stirrup diameter is 5mm.

[0051] The main difference between this square pile and the embodiment is the difference in the number of main reinforcements used and the use of different main reinforcement structures. Therefore, this embodiment only introduces the differences from Embodiment 1 here.

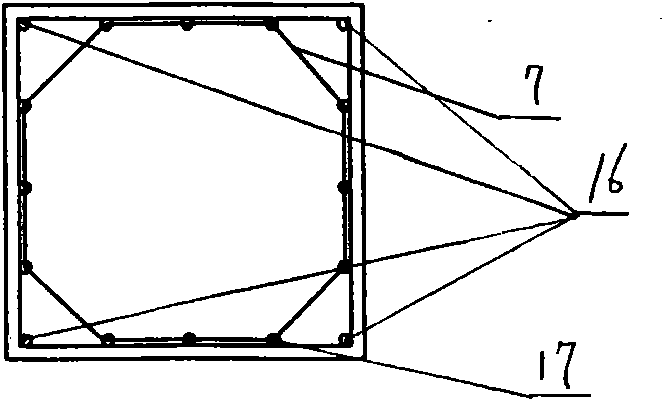

[0052] In this embodiment, the prestressed main reinforcement is used in combination with the four-corner prestressed main reinforcement and the inner four-corner prestressed main reinforcement, such as Figure 6 As shown, the four corners of the square pile are the four-corner prestressed main reinforcement, and the four main reinforcements at the center of the four sides of the square pile constit...

Embodiment 3

[0054] According to the needs of a certain project, a steel pile tip fully prestressed concrete whole solid square pile is designed and produced, with a cross-section of 350×350 (mm), a length of 18 meters, and a total of 8 prestressed main reinforcements with a diameter of 9mm. , The stirrup diameter is 5mm.

[0055] The main difference between this square pile and the embodiment is the difference in the number of main reinforcements used and the use of different main reinforcement structures. Therefore, this embodiment only introduces the differences from Embodiment 1 here.

[0056] In this embodiment, the prestressed main reinforcement is used in combination with the four-corner prestressed main reinforcement and the inner four-corner prestressed main reinforcement, such as Figure 7 As shown, the four corners of the square pile are the four-corner prestressed main reinforcement, and the four main reinforcements at the center of the four sides of the square pile constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com