Colorizing method of building decoration microcrystalline glass produced by sintering method

A technology for glass-ceramic and architectural decoration, applied in the field of preparation of glass-ceramic decorative plates, can solve the problems of uneven coloring of glass, energy consumption, increase in production cost, etc., and achieve the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

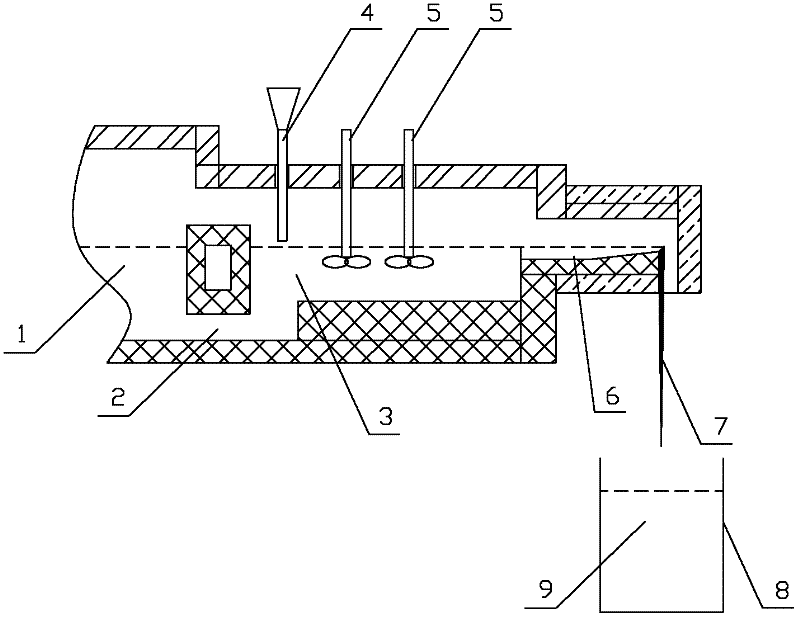

Image

Examples

Embodiment 1

[0029] A kind of coloring method of sintered architectural decorative glass-ceramic, it comprises the following steps:

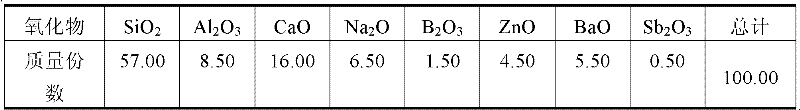

[0030] 1) Ingredients: the basic composition range of the glass-ceramics used in this embodiment is shown in Table 1:

[0031] Table 1 (number of parts by mass)

[0032]

[0033] Calculate the ingredients based on the content of the components in Table 1, and obtain the ingredient list. Use mineral raw materials and chemical raw materials to introduce various oxides, weigh and mix them to obtain glass batches. The glass raw material ingredient list is shown in Table 2.

[0034] Table 2 Glass raw material ingredient list

[0035] raw material

Purity (%)

Dosage(kg)

SiO 2

98.5

57.87

al 2 o 3

99.5

8.54

CaCO 3

98.5

29.16

Na 2 CO 3

98.5

11.45

h 3 BO 3

98.5

2.75

ZnO

98.5

4.57

BaCO 3

98.5

7.08

...

Embodiment 2

[0042] A kind of coloring method of sintered architectural decorative glass-ceramic, it comprises the following steps:

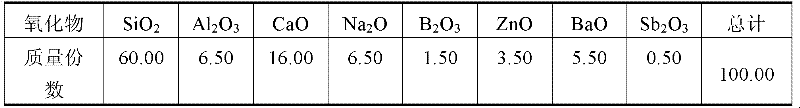

[0043] 1) Ingredients: the basic composition range of the glass-ceramic glass used in this embodiment is shown in Table 3:

[0044] Table 3 (number of parts by mass)

[0045]

[0046] Calculate the ingredients based on the content of the components in Table 3, and obtain the ingredient list. Use mineral raw materials and chemical raw materials to introduce various oxides, weigh and mix them to obtain glass batches. The list of glass raw material ingredients is shown in Table 4.

[0047] Table 4 Glass Raw Material Ingredients List

[0048] raw material

Purity (%)

Dosage(kg)

SiO 2

98.5

60.91

Al 2 o 3

99.5

6.53

CaCO 3

98.5

29.16

Na 2 CO 3

98.5

11.45

h 3 BO 3

98.5

2.75

ZnO

98.5

3.55

BaCO 3

98.5

...

Embodiment 3

[0055] A kind of coloring method of sintered architectural decorative glass-ceramic, it comprises the following steps:

[0056] 1) Ingredients: The basic composition range of the glass-ceramics used in this embodiment is shown in Table 5:

[0057] Table 5 (number of parts by mass)

[0058]

[0059] Calculate the ingredients based on the content of the components in Table 5 to obtain the ingredient list, introduce various oxides with mineral raw materials and chemical raw materials, weigh and mix them to obtain glass batch materials. The glass raw material ingredient list is shown in Table 6.

[0060] Table 6 glass raw material ingredient list

[0061] raw material

Purity (%)

Dosage(kg)

SiO 2

98.5

61.93

al 2 o 3

99.5

5.53

CaCO 3

98.5

32.81

Na 2 CO 3

98.5

9.69

h 3 BO 3

98.5

1.32

ZnO

98.5

3.55

BaCO 3

98.5

6.44...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com