White light radiation glass for rare earth ion europium activating lamp and preparation method thereof

The technology of rare earth ions and alkaline earth metal ions is applied in the field of preparation of white light-emitting glass, and achieves the effects of eliminating powder coating process, high luminous brightness and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

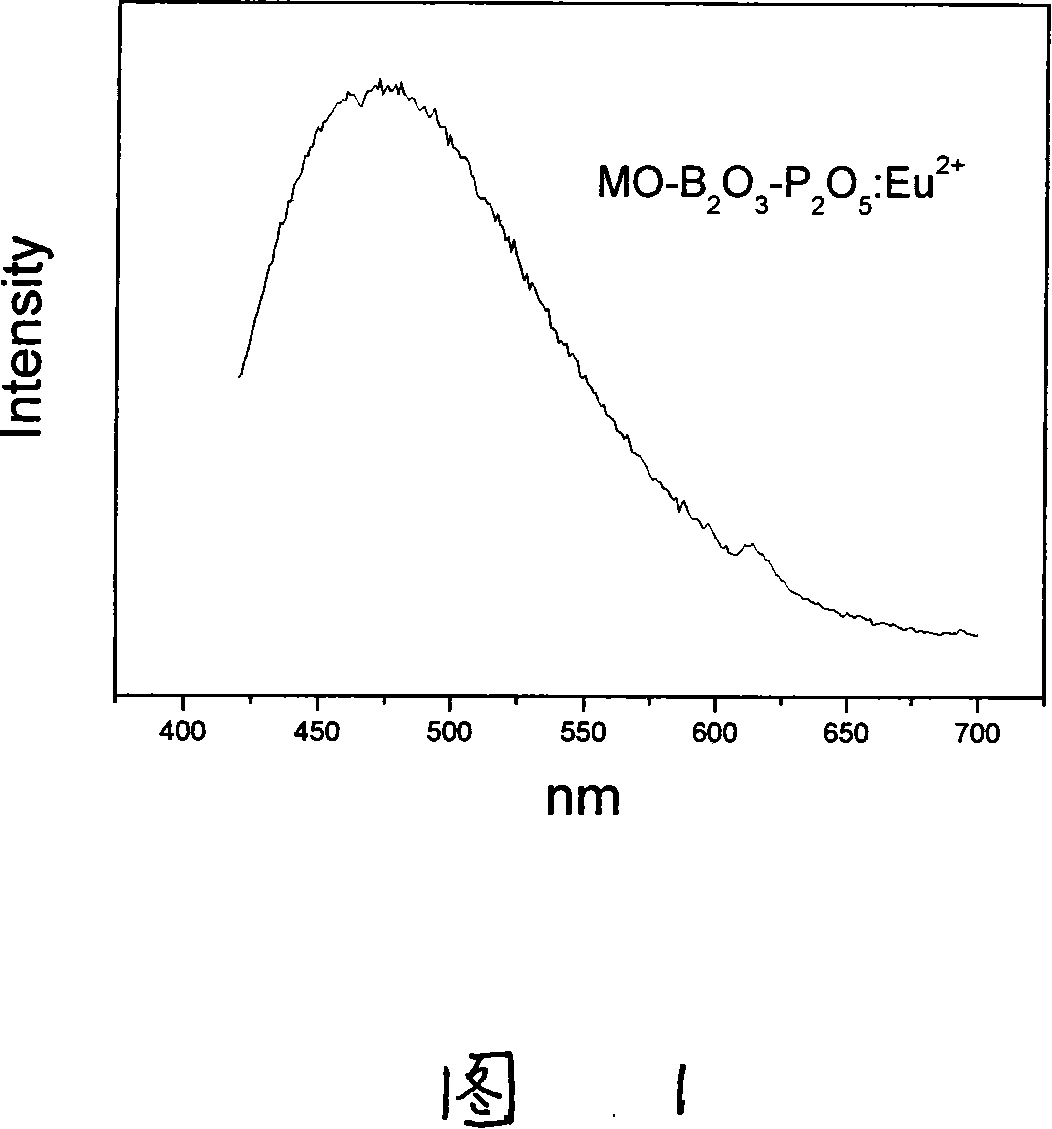

Image

Examples

Embodiment 1

[0013] Each component of this glass composition is weighed by the following mole percentages:

[0014] CaO: 0.350; B 2 o 3 : 0.400;

[0015] NH 4 h 2 P 2 o 5 : 0.250; Eu 2 o 3 : 0.001.

[0016] CaCO will be accurately weighed according to the composition ratio 3 , B 2 o 3 , NH 4 h 2 P 2 o 5 、Eu 2 o 3 , Grinding and mixing, pass hydrogen into the furnace as a reducing atmosphere, and keep the temperature at 1500°C for 5.0h. After the glass is out of the furnace, it is shaped and annealed to obtain the final product.

Embodiment 2

[0018] Each component of this glass composition is weighed by the following mole percentages:

[0019] SrO: 0.450; B 2 o 3 : 0.250;

[0020] NH 4 h 2 P 2 o 5 : 0.300; Eu 2 o 3 : 0.010.

[0021] BaCO will be accurately weighed according to the composition ratio 3 , B 2 o 3 , NH 4 h 2 P 2 o 5 、Eu 2 o 3 , after grinding and mixing, put CO gas into the furnace as a reducing atmosphere, and keep the temperature at 1300°C for 3.0h. After the glass is out of the furnace, it is shaped and annealed to obtain the final product.

Embodiment 3

[0023] Each component of this glass composition is weighed by the following mole percentages:

[0024] BaO: 0.550; B 2 o 3 : 0.280;

[0025] NH 4 h 2 P 2 o 5 : 0.270; Eu 2 o 3 : 0.010.

[0026] BaCO will be accurately weighed according to the composition ratio 3 , B 2 o 3 , NH 4 h 2 P 2 o 5 、Eu 2 o 3 , After grinding and mixing, keep the temperature at 1100°C for 1.0h under air condition. After the glass is out of the furnace, it is shaped and annealed to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com