Device and technique for continuously melting transparent quartz glass ingot by gas refining

A technology for transparent quartz and glass ingots, applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., can solve problems such as inability to manufacture non-circular cross-section ingots and intermittent production of a single ingot, achieve uniform appearance and improve production Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

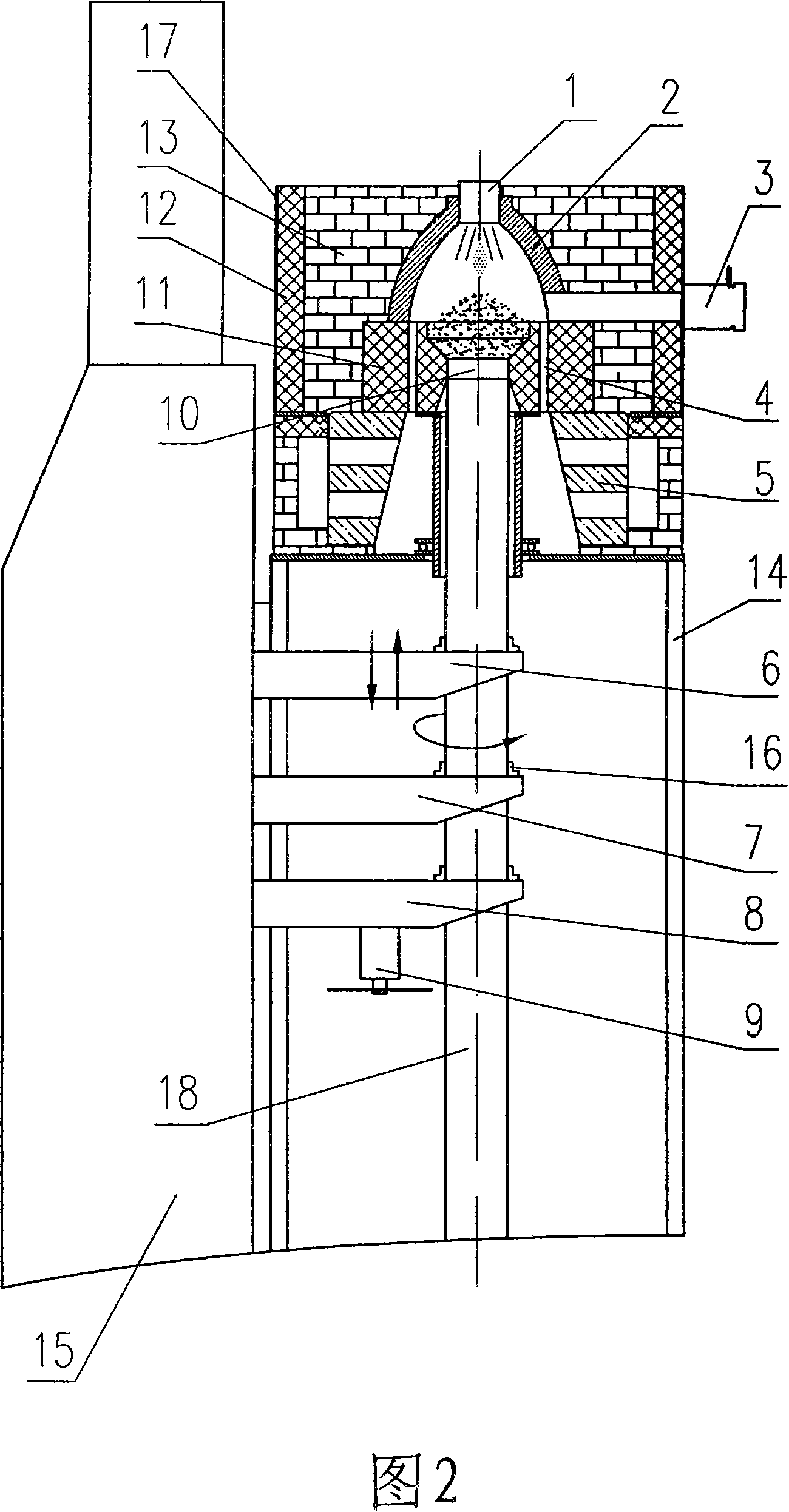

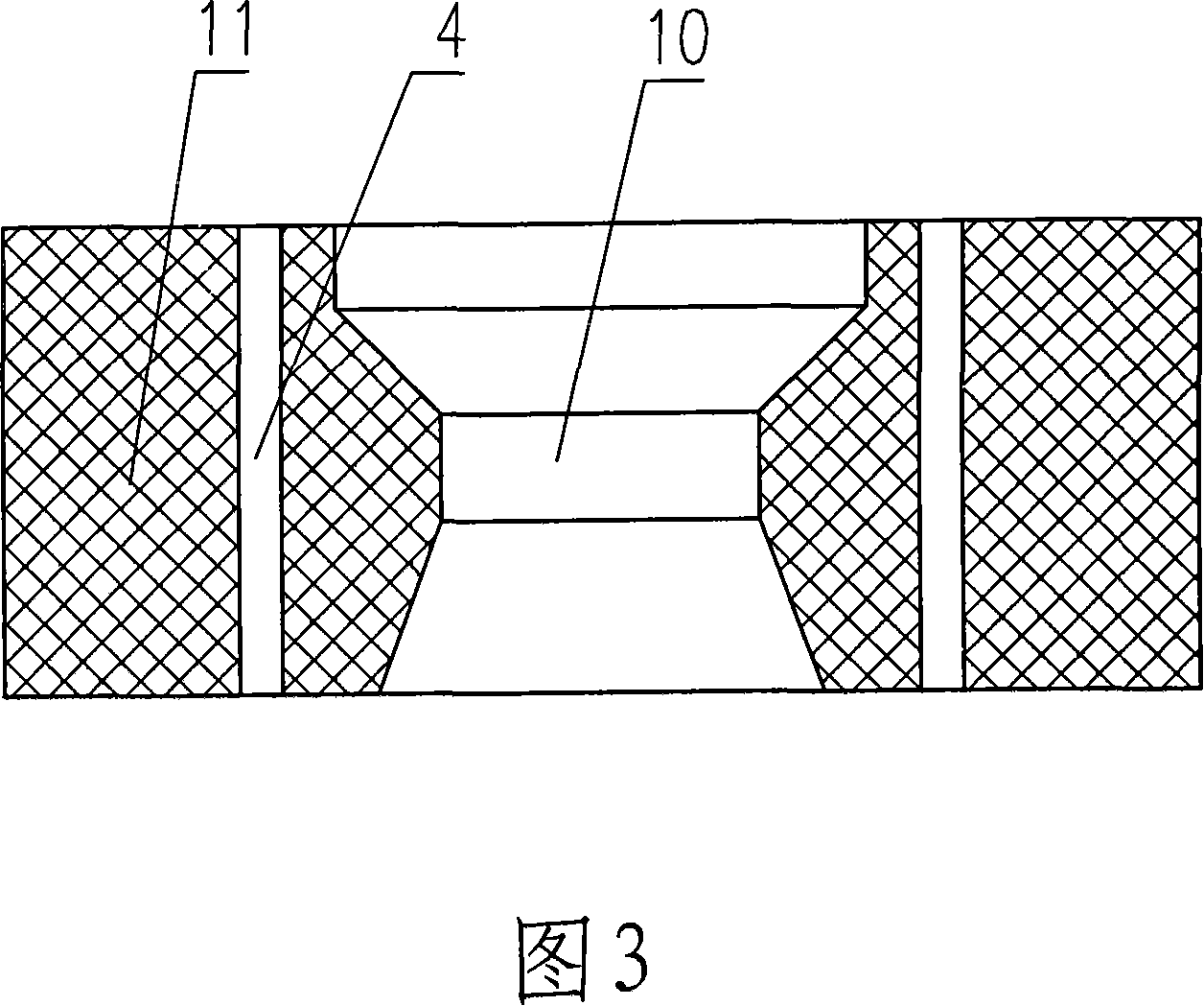

[0023] The melting equipment for continuously melting transparent quartz glass ingots in this gas refinery consists of a hydrogen-oxygen burner 1, a furnace 2, an observation hole 3, an exhaust port 4, an annular checker brick flue 5, an upper cross arm 6, and a middle cross arm 7 , cutting cross arm 8, cutting device 9, forming port 10, molten pool 11, heat insulating blanket 12, heat insulating brick 13, furnace base 14, drawing machine 15, chuck 16 and steel furnace shell 17 constitute (see accompanying drawing 2 -3). The furnace body made of thermal insulation brick 13, thermal insulation blanket 12 and steel furnace shell 17 is contained in the top of furnace base 14, and furnace 2 is housed in it, and a hydrogen-oxygen burner 1 is housed on the top of furnace 2, and the middle part of furnace 2 is equipped with There are observation holes 3. The inner surface of the furnace 2 is in the shape of a paraboloid. The lower part of the furnace 2 is fixed with a molten pool 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com