Glass-melting extrusion 3D (three-dimensional) printing device

A 3D printing and glass melting technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reduced equipment service life, increased cost, opaque dimensional accuracy of printed samples, etc., to avoid shortened life and improve Cooling effect, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

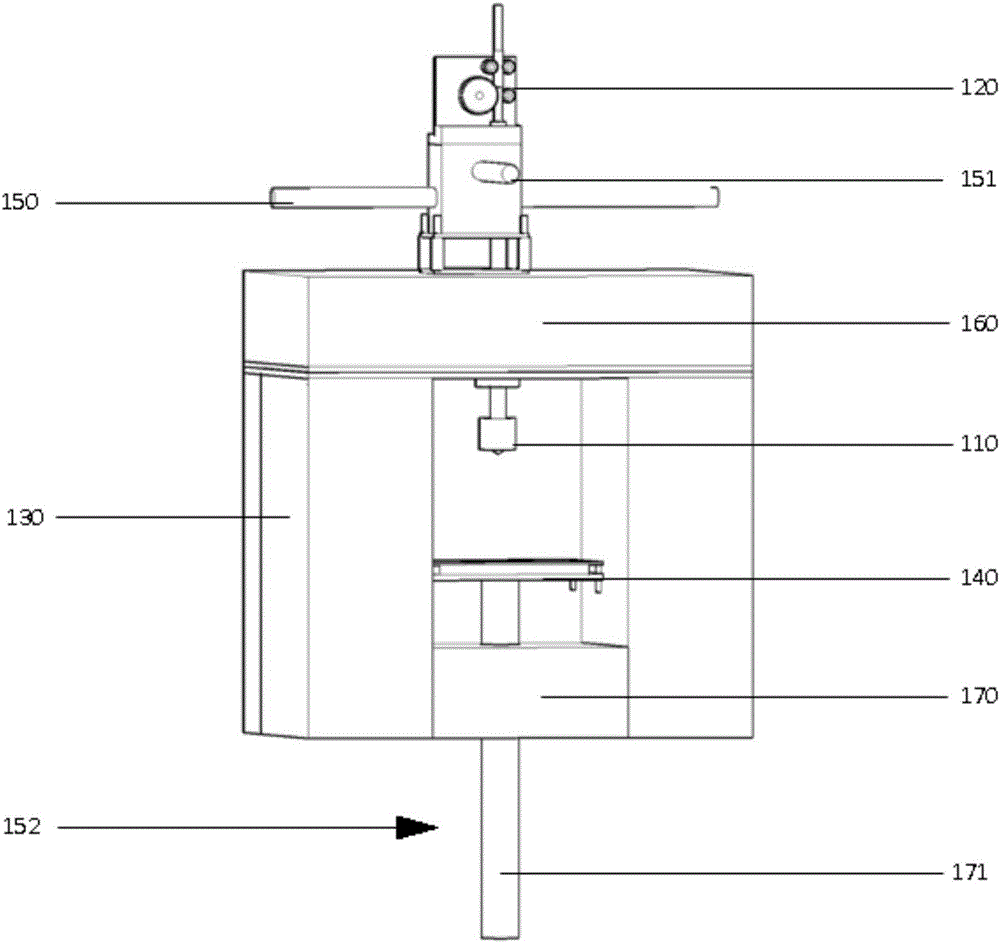

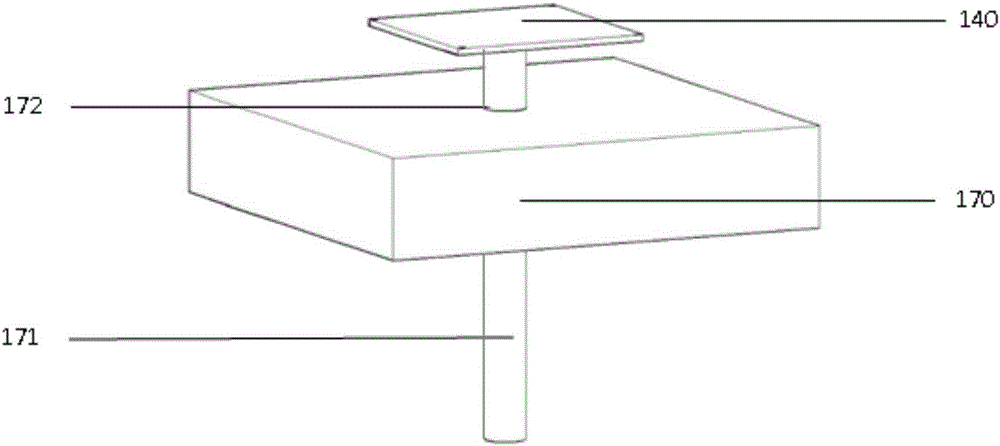

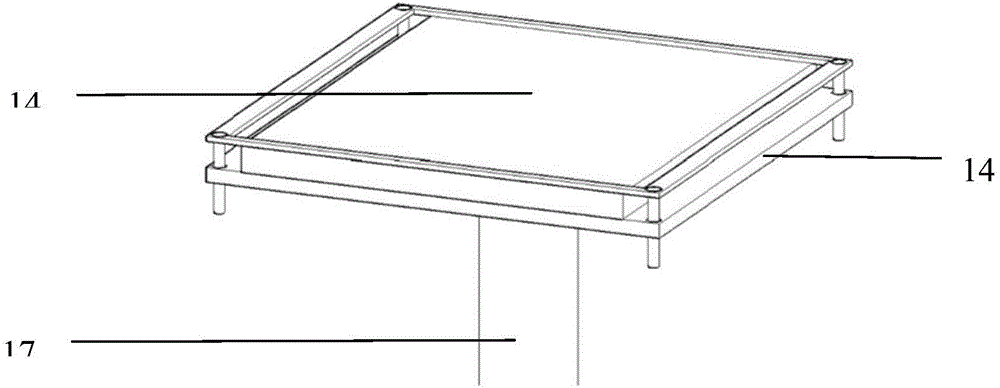

[0045] Such as Figure 1~3 As shown, the glass melting extrusion 3D printing device of this embodiment includes: a programmable heating and cooling molding chamber 130; a feeding mechanism 120, which sends the glass material to the printing nozzle assembly 110 and provides molten glass extrusion force; the printing nozzle assembly 110 , the glass printing material is melted and extruded in the printing nozzle assembly 110; the printing platform 140 located in the molding chamber 130; the XY axis positioning system 150 (translation), 151 and the Z axis positioning system 152 (lifting ), and is thermally isolated from the molding chamber 130 by the movable heat insulating board 160; The combination.

[0046] The print nozzle assembly 110 includes a high temperature resistant cooling module 111 arranged outside the molding chamber 130 and a nozzle 112 with a heating system arranged inside the molding chamber 130. The high temperature resistant cooling module 111 passes through t...

Embodiment 2

[0062] Such as Figure 6 As shown, in this embodiment, except for the feeding mechanism, the rest of the structure is the same as that of Embodiment 1. The feeding mechanism 120 adopts a screw-type feeding device, and the glass powder 190 enters through the barrel 191 and the feed channel 192 through the extrusion of the compressed air 195. Screw 194. The rotation speed of the screw 194 is controlled by the motor 193 , so as to adjust the rate at which the glass powder 190 enters the print nozzle assembly 110 , thereby improving the accuracy of the printed product.

[0063] When printing, the glass material passes through the feeding mechanism 120 and enters the nozzle 112 along the feeding direction 200, where it melts into a molten state and is extruded from the nozzle 112 under the drive of the positioning system and deposited on the printing platform 140 layer by layer. The forming chamber 130 Maintain a temperature of at least 650°C inside to ensure the interlayer bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com