Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

A technology for glass-ceramic and blast furnace slag, which is applied in the production field of glass-ceramic, can solve the problems of difficulty, the progress is not obvious, and TiO2 affects the crystallization effect of glass-ceramic, so as to reduce the production cost and reduce the energy consumption of the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

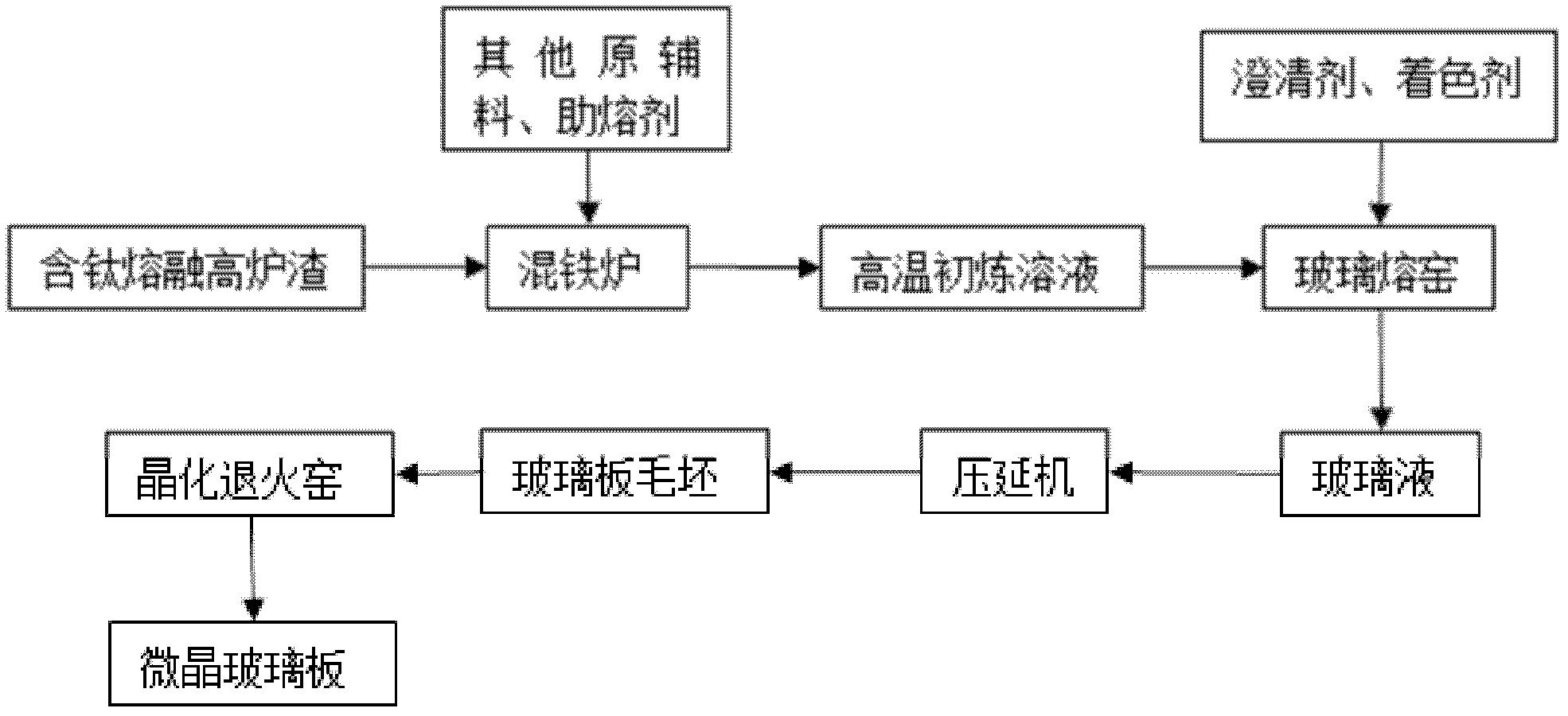

[0032] The method for preparing glass-ceramics from titanium-containing molten blast furnace slag provided in this embodiment comprises the following steps:

[0033] (1) Send the 1400°C titanium-containing molten blast furnace slag flowing out of the blast furnace into the iron mixing furnace for heating and heat preservation, and mix it with silica sand, clay, albite and flux to form a high-temperature primary smelting solution;

[0034] (2) Input the high-temperature primary refining solution into a glass melting furnace, heat it to 1550° C., add clarifiers and colorants to refine it for 1 hour, and make it into a glass solution;

[0035] (3), the glass solution is entered into a calender to be pressed into a red-hot glass plate blank;

[0036] (4) The pressed glass plate blank is sent into the crystallization annealing kiln, heat-preserved and crystallized at 1000°C for 2 hours, and annealed and heat-preserved at 550°C for 1 hour to make glass-ceramics;

[0037] (5) Edge g...

Embodiment 2

[0042] The method for preparing glass-ceramics from titanium-containing molten blast furnace slag provided in this embodiment comprises the following steps:

[0043] (1) Send the 1560°C titanium-containing molten blast furnace slag flowing out of the blast furnace into the iron mixing furnace for heating and heat preservation, and mix it with silica sand, clay, albite and flux as a high-temperature primary smelting solution;

[0044] (2) Input the high-temperature primary refining solution into a glass melting furnace, heat it to 1600° C., add clarifiers and colorants for refining for 2 hours, and make it into a glass solution;

[0045] (3), the glass solution is entered into a calender to be pressed into a red-hot glass plate blank;

[0046] (4) The pressed glass plate blank is sent into the crystallization annealing kiln, heat-preserved and crystallized at 1100°C for 3 hours, and annealed and heat-preserved at 650°C for 2 hours to make glass ceramics;

[0047] (5) Edge grin...

Embodiment 3

[0052] The method for preparing glass-ceramics from titanium-containing molten blast furnace slag provided in this embodiment comprises the following steps:

[0053](1) Send the 1470°C titanium-containing molten blast furnace slag flowing out of the blast furnace into the iron mixing furnace for heating and heat preservation, and mix it with silica sand, clay, albite and flux as a high-temperature primary smelting solution;

[0054] (2) Input the high-temperature primary refining solution into a glass melting furnace, heat it to 1580° C., add clarifiers and colorants to refine for 1.5 hours, and make it into a glass solution;

[0055] (3), the glass solution is entered into a calender to be pressed into a red-hot glass plate blank;

[0056] (4) The pressed glass plate blank is sent into the crystallization annealing kiln, heat-preserved and crystallized at 1050°C for 2.5 hours, and annealed at 600°C for 1.5 hours to make glass-ceramics;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com