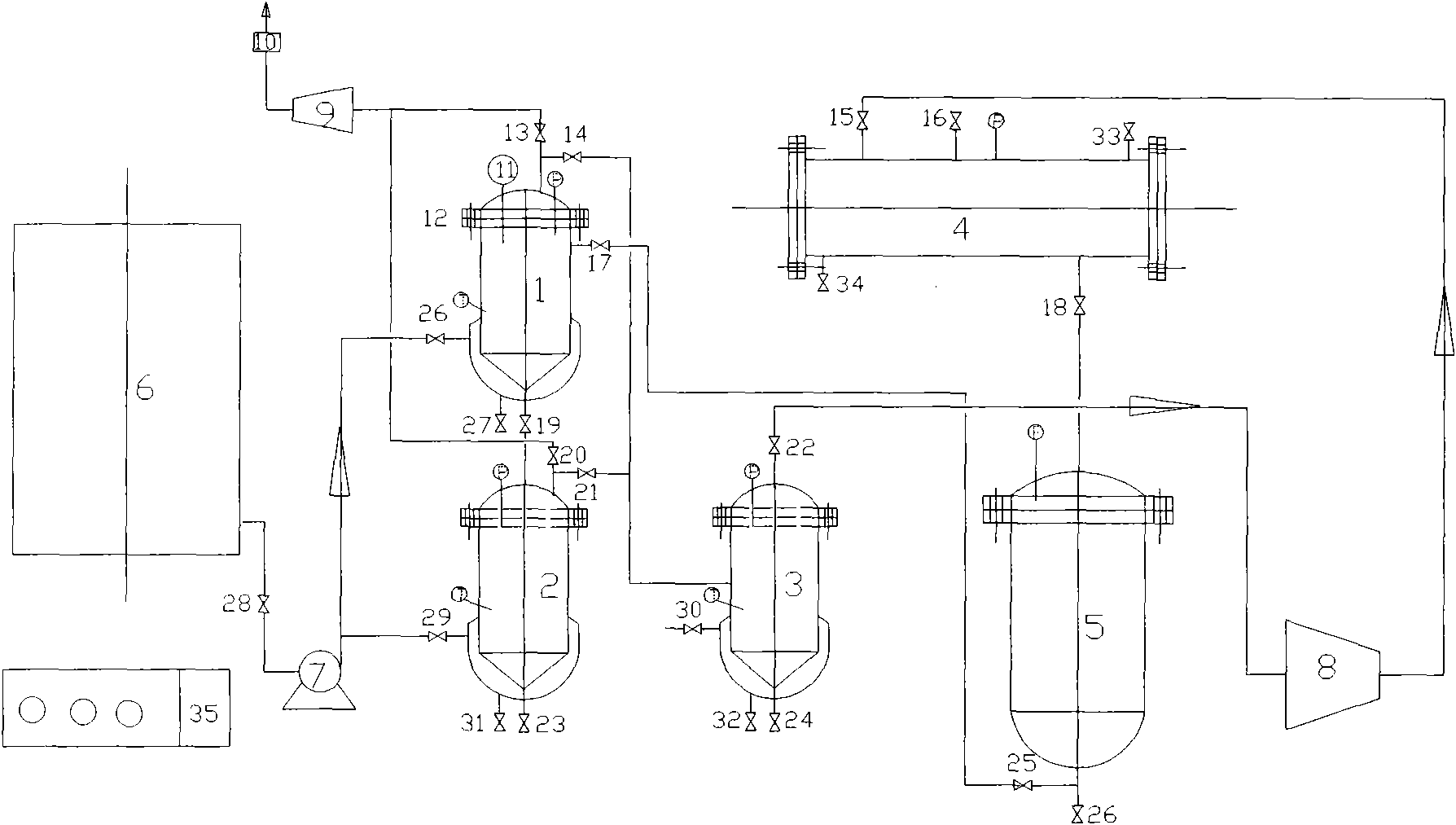

Subcritical liquid extraction device and subcritical liquid extraction method of active ingredients of natural products

A subcritical fluid and active ingredient technology, applied in the direction of solid solvent extraction, etc., can solve the problems of being limited to a specific subcritical fluid, cumbersome loading and unloading of extraction kettles, and high working pressure of equipment, so as to reduce solvent loss and low operating costs , The effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Subcritical Liquefied Petroleum Gas Extraction of Natural Greenthorn Fruit Oil

[0046] Take 2.5kg of natural green sorrel fruit, the raw material contains 0.3% impurities after pretreatment, the thickness of the embryo sheet is 0.35mm, the water content is 8.5%, and the temperature is 45°C. Then subcritical liquefied petroleum gas was used as the lysozyme to extract the thorn fruit oil, the extraction temperature was 45°C, the extraction time was 45 minutes, and the extraction times were 5 times. The mixed oil is decompressed and gasified, and when it reaches 0Mpa (gauge pressure), it is vacuumed and precipitated. When the gauge pressure is -0.09MPa, it is kept at a temperature of 45°C for 30min. The wet material embryo is decompressed and gasified, and the lysozyme is recovered by compression. Determination results of the main quality indicators of the green thorn fruit oil: 0.85ppm residual solubility in the oil; 0.1% impurity; 2.0% oil content in the meal...

Embodiment 2

[0047] Example 2 Ultrasonic-assisted subcritical propane extraction of natural green thorn fruit oil

[0048] Take 2.5kg of natural green sorrel fruit, the raw material contains 0.3% impurities after pretreatment, the thickness of the embryo sheet is 0.35mm, the water content is 8.5%, and the temperature is 45°C. Then subcritical propane was used as the lysozyme, and the thorn fruit oil was extracted with ultrasonic assistance. The extraction temperature was 45°C, the extraction time was 30 minutes, the extraction times were 3 times, the ultrasonic power was 1500W, and the ultrasonic frequency was 20KHz. The mixed oil is decompressed and gasified, and when it reaches 0Mpa (gauge pressure), it is vacuumed and precipitated. When the gauge pressure is -0.09MPa, it is kept at a temperature of 45°C for 30min. The wet material embryo is decompressed and gasified, and the lysozyme is recovered by compression. Determination results of the main indicators of green thorn fruit oil: res...

Embodiment 3

[0049] Example 3 Subcritical propane and butane extraction of wheat germ oil

[0050] Take 2.5kg of wheat germ, after cleaning, microwave drying and other pretreatments, the impurity content is 0.15%, and the water content is 7.5%. Using subcritical propane and butane, the extraction is carried out according to the countercurrent three-immersion process. The first and second times are respectively extracted with the second and third times of mixed oil leached from the previous tank, and each time is soaked for 35 minutes. The mixed oil leached in the first pass is pumped into the evaporation tank, and the other two passes are pumped into the buffer tank. The leaching temperature is room temperature, the pressure is 0.4MPa, the ratio of material to solution is 1:2.5, and the ratio of propane to butane is 3:1. When the mixed oil evaporates, the temperature of the circulating hot water is controlled below 50°C, and when it reaches 0Mpa (gauge pressure), it is vacuumed and precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com