Micro-channel heat sink

a microchannel heat sink and heat sink technology, applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problem that the bubbles in the boiling fluid cannot easily flow backwards, and achieve high heat transfer capability, high power efficiency, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following will demonstrate the present invention using the accompanying drawings to clearly present the characteristics of the technology.

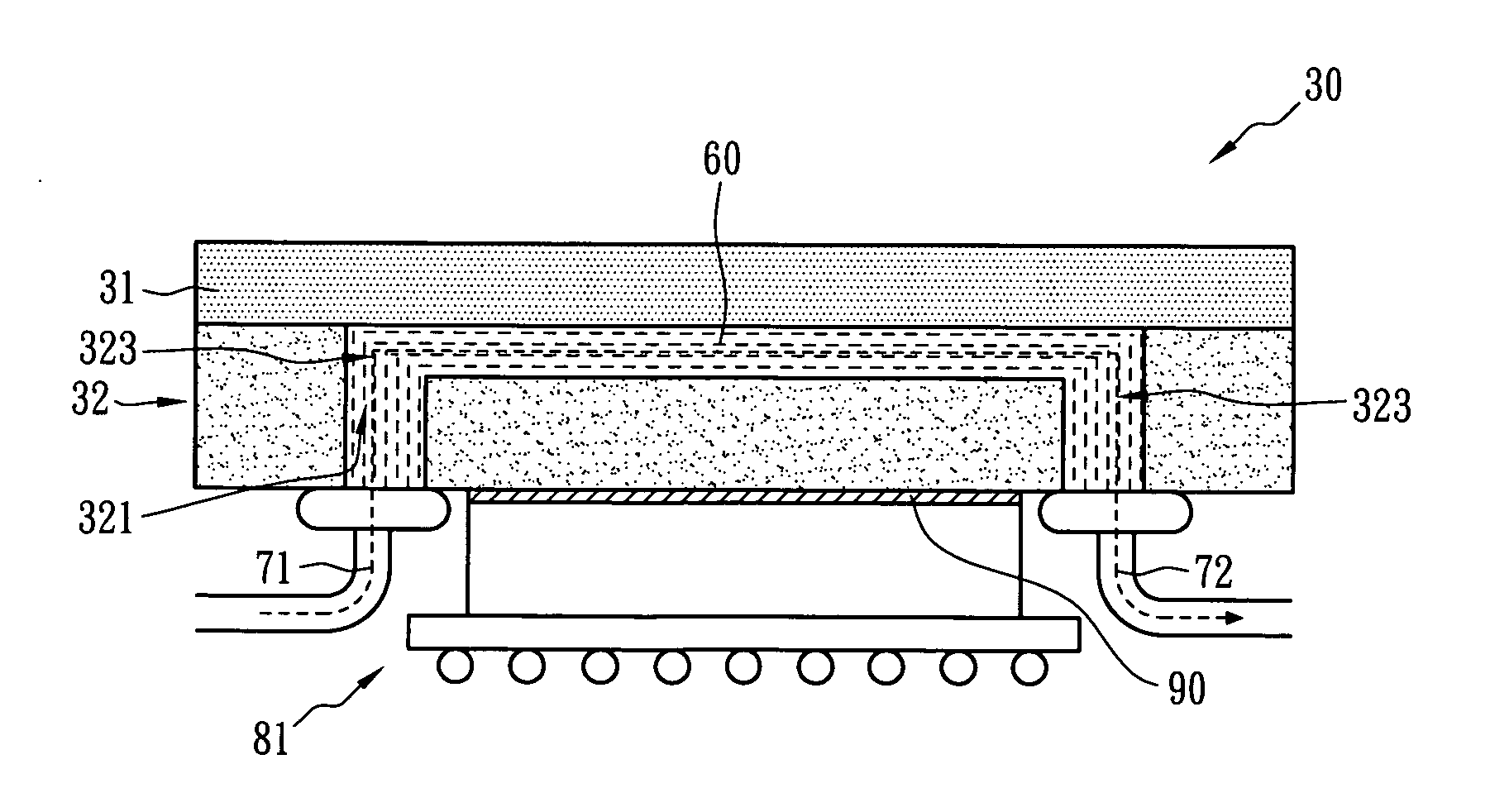

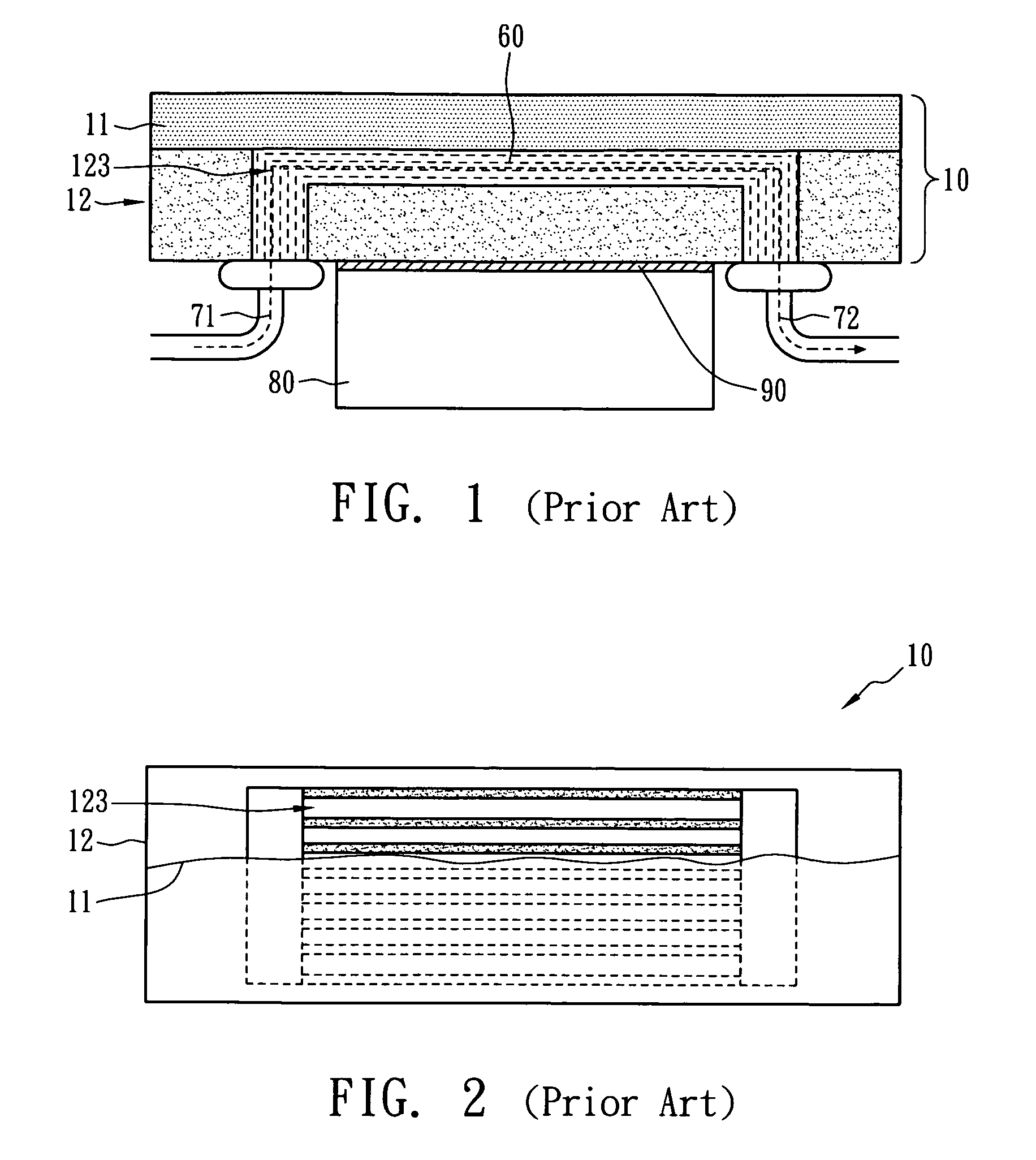

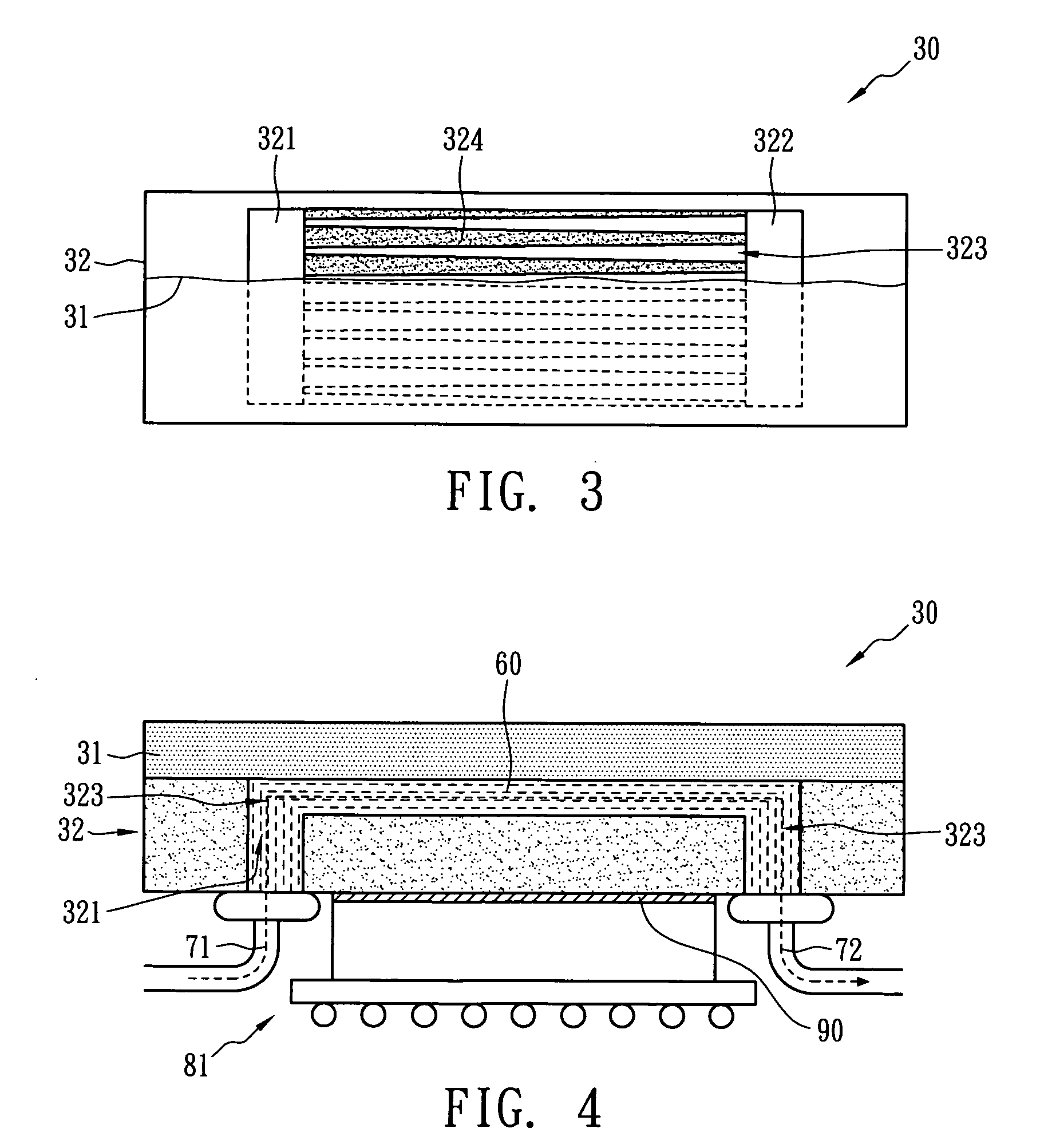

[0020]FIG. 3 is a top view showing a micro-channel heat sink in accordance with the present invention. The micro-channel heat sink 30 comprises an upper cover layer 31 and a cooling layer 32, wherein the cooling layer32 comprises at least one inlet fluid tank 321, a plurality of micro-channels 323, and at least one outlet fluid tank 322. The inlet fluid tank 321 can store and deliver the working fluids, and the outlet fluid tank 322 collects the heated working fluids flowing through the plurality of micro-channels. The plurality of micro-channels 323 is disposed between the inlet fluid tank 321 and the outlet fluid tank 322. The cross-sectional area of each of the micro-channels 323 gradually increases along the direction from the inlet fluid tank 321 towards the outlet fluid tank 322, and, conversely, the cross sectional area of the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com