Flow-dividing annular micro-channel radiator

A radiator and micro-channel technology, applied in the field of new micro-channel radiators, can solve the problem of uneven flow distribution, achieve good application prospects, improve uneven flow distribution, and improve the overall heat transfer capacity and heat transfer limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

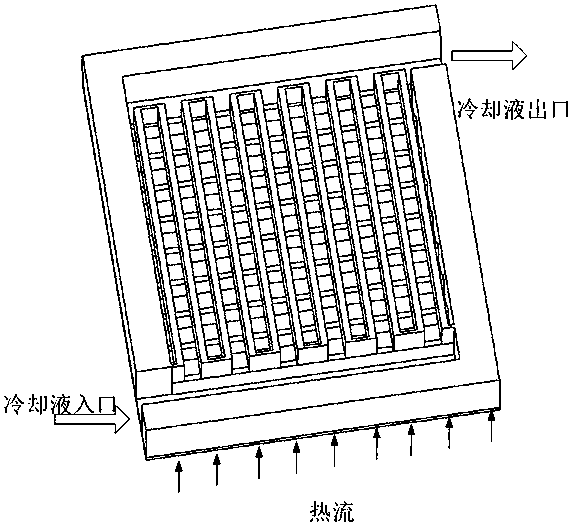

[0026] What this embodiment described is a split-type microchannel heat sink with multiple inlets and single outlets, such as figure 2 As shown, it consists of a circular micro rib 1 , a circular flow distribution structure 2 and a cover plate 3 .

[0027] see image 3 , the circular micro-rib 1 includes a primary distribution channel 1-1, an annular micro-rib 1-2 and a positioning hole 1-3. The material of the micro-rib 1 is first considered to be a metal material with good thermal conductivity, and its bottom surface is bonded to the heating element through thermal silica gel or thermal grease. The cooling working fluid enters the secondary distribution channel from the annular primary distribution channel 1-1. The height of the annular micro-ribs 1-2 and the spacing of the micro-ribs are on the order of millimeters or microns to increase the heat exchange area, and the specific size is determined according to actual needs.

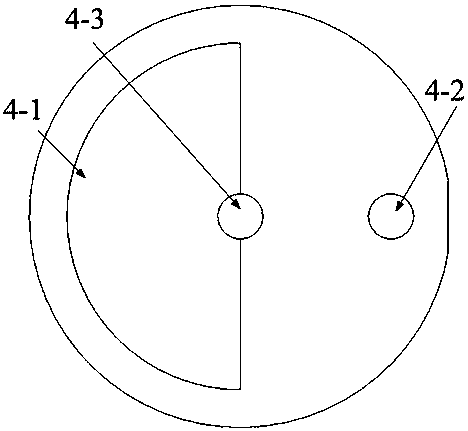

[0028] see Figure 4 , the circular distribu...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, see Figure 7 The difference is that: the water inlet and outlet are in the form of single inlet and single outlet, which reduces the number of external pipes connected to the heat sink; in addition, an inlet and outlet water structure layer is added to improve the uneven distribution of the first flow caused by the single inlet structure.

[0033] The circular micro ribs 1 in this embodiment are the same as those in the first embodiment.

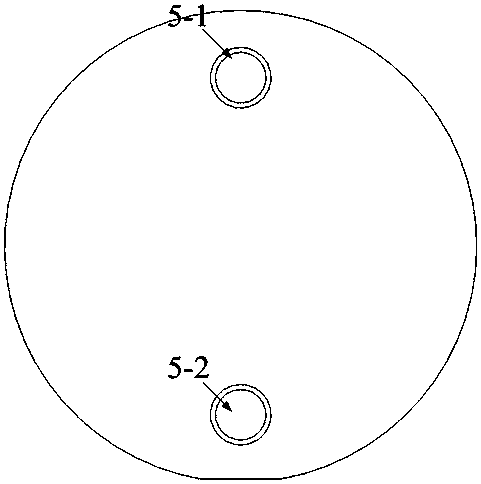

[0034] see Figure 8 , the circular distribution structure 2 includes an inlet water flow channel 2-1, an outlet water flow channel 2-2, a cover plate 2-3, a water outlet channel 2-4 and a positioning pin 2-5. The size of the shunt structure 2 is smaller than that of the circular micro-rib 1 to form an annular channel as a primary annular shunt channel. The cooling working fluid enters the water outlet structure layer 4 through the water outlet channels 2-4.

[0035] see Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com