Micro-channel radiator for dissipating heat of power electronic device

A technology for power electronic devices and heat sinks, applied in the field of micro-channel heat sinks, can solve problems such as unfavorable chip stable operation, uneven temperature distribution, and difficult realization of multiple inlets and outlets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

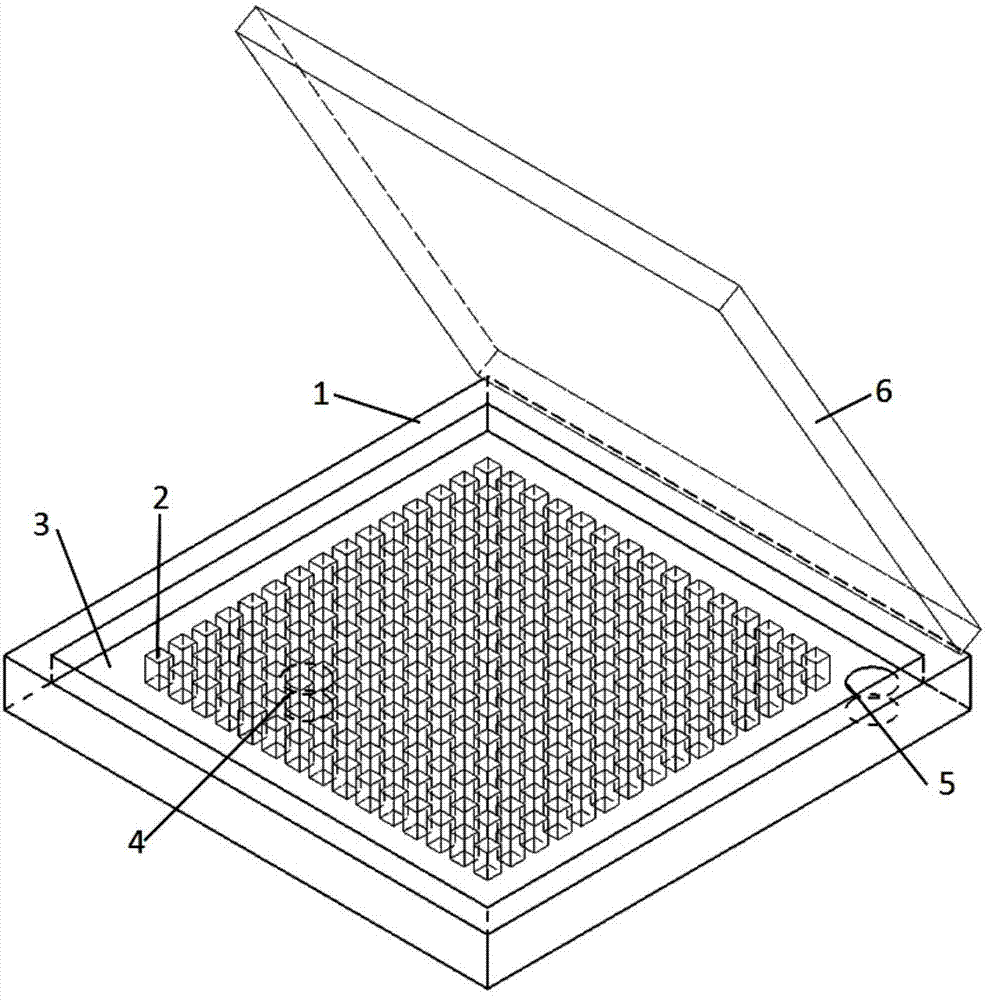

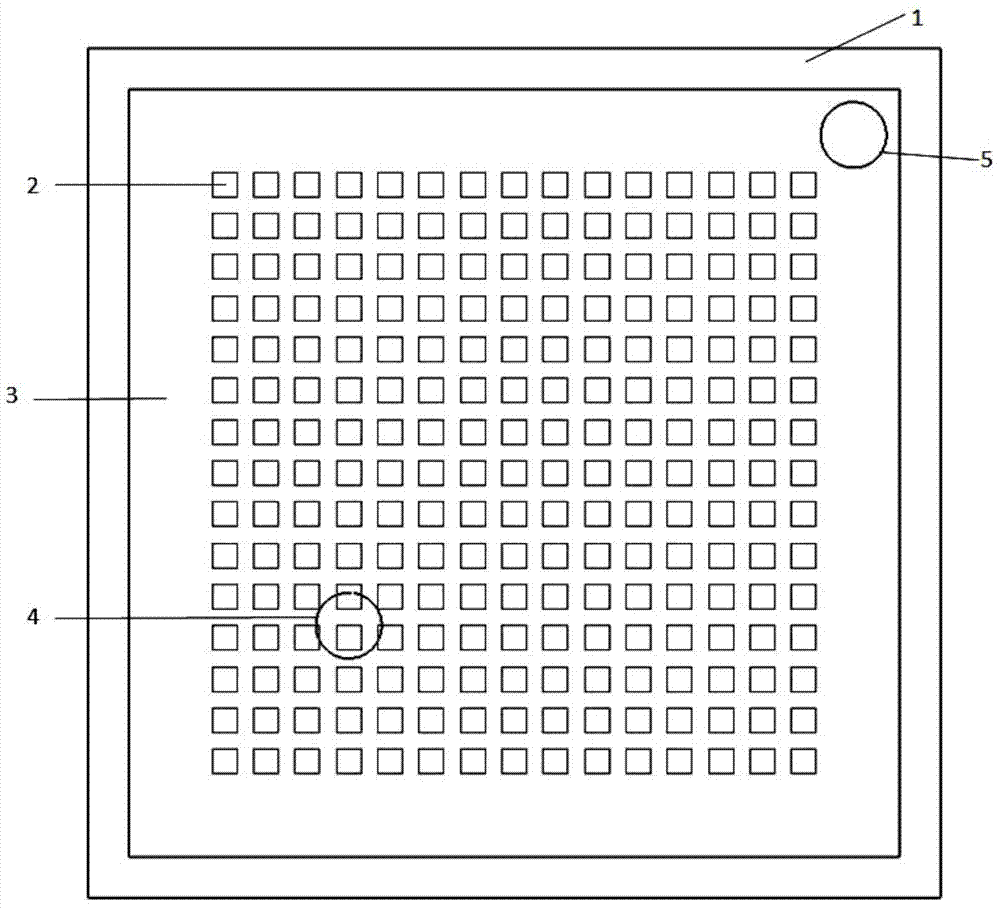

[0029] Such as figure 1 , figure 2 , image 3 As shown, the present embodiment provides a microchannel heat sink for heat dissipation of power electronic devices, including: heat sink outer wall 1, internal flow channel structure 2, heat dissipation working medium 3, working medium inlet 4, working medium outlet 5 and upper layer Cover plate 6, wherein: a flow guide channel is provided between the outer wall 1 of the radiator and the internal flow channel structure 2 to facilitate the outflow of the heat-dissipating working medium 3; the working medium outlet 5 is arranged at the One corner; the working fluid inlet 4 is arranged on the heat dissipation surface of the radiator and deviates from the center of the heat dissipation surface, and away from the side of the working medium outlet 5; the heat dissipation chip is connected to the upper cover plate 6, and its heat passes through the upper layer The cover plate 6 and the internal flow channel structure 2 connected there...

Embodiment 2

[0041] Such as Figure 4 , Figure 5 , Image 6As shown, this embodiment provides a microchannel radiator for heat dissipation of power electronic devices, including: radiator outer wall 1, internal flow channel structure 2, heat dissipation working medium 3, working medium inlet 4, working medium outlet 5 and upper layer The cover plate 6 and the connection of components are the same as those in Embodiment 1, and the position of the working fluid inlet 4 is slightly different.

[0042] In this embodiment, the internal flow channel structure 2 is a honeycomb cylindrical spoiler column, and a micro flow channel is formed between the spoiler columns; the radius of the spoiler column is 0.3mm, and the height is 0.5mm; the spoiler column The spacing between stream columns is 0.2mm.

[0043] In this embodiment, the hydraulic diameter of the working fluid outlet 5 is 0.7 mm.

[0044] In this embodiment, the hydraulic diameter of the working fluid inlet 4 is 0.7 mm.

[0045] In ...

Embodiment 3

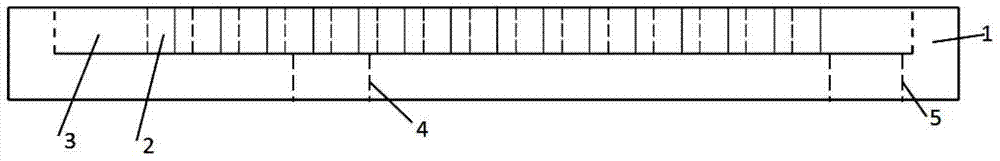

[0053] Such as Figure 7 , Figure 8 , Figure 9 As shown, this embodiment provides a microchannel radiator for heat dissipation of power electronic devices, including: radiator outer wall 1, internal flow channel structure 2, heat dissipation working medium 3, working medium inlet 4, working medium outlet 5 and upper layer The cover plate 6 and the connection of components are the same as those in Embodiment 1.

[0054] In this embodiment, the internal channel structure 2 is a honeycomb cuboid spoiler column, and micro-channels are formed between the spoiler columns; the narrow side of the spoiler column is 0.1mm wide and 0.5mm high; The spacing between spoiler columns is 0.3mm or 0.5mm.

[0055] In this embodiment, the hydraulic diameter of the working fluid outlet 5 is 0.8 mm.

[0056] In this embodiment, the hydraulic diameter of the working fluid inlet 4 is 0.8 mm.

[0057] In this embodiment, the width of the drainage channel is 1mm.

[0058] In this embodiment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com