Lotus-type regular porous metal microchannel heat sink using liquid metal working medium

A technology of liquid metal and porous metal, applied in cooling/ventilation/heating transformation, semiconductor/solid-state device components, lasers, etc., can solve problems such as difficult processing, large pressure drop at import and export, complex structure, etc., and achieve a wide range of applications , The effect of small pressure drop at the inlet and outlet, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

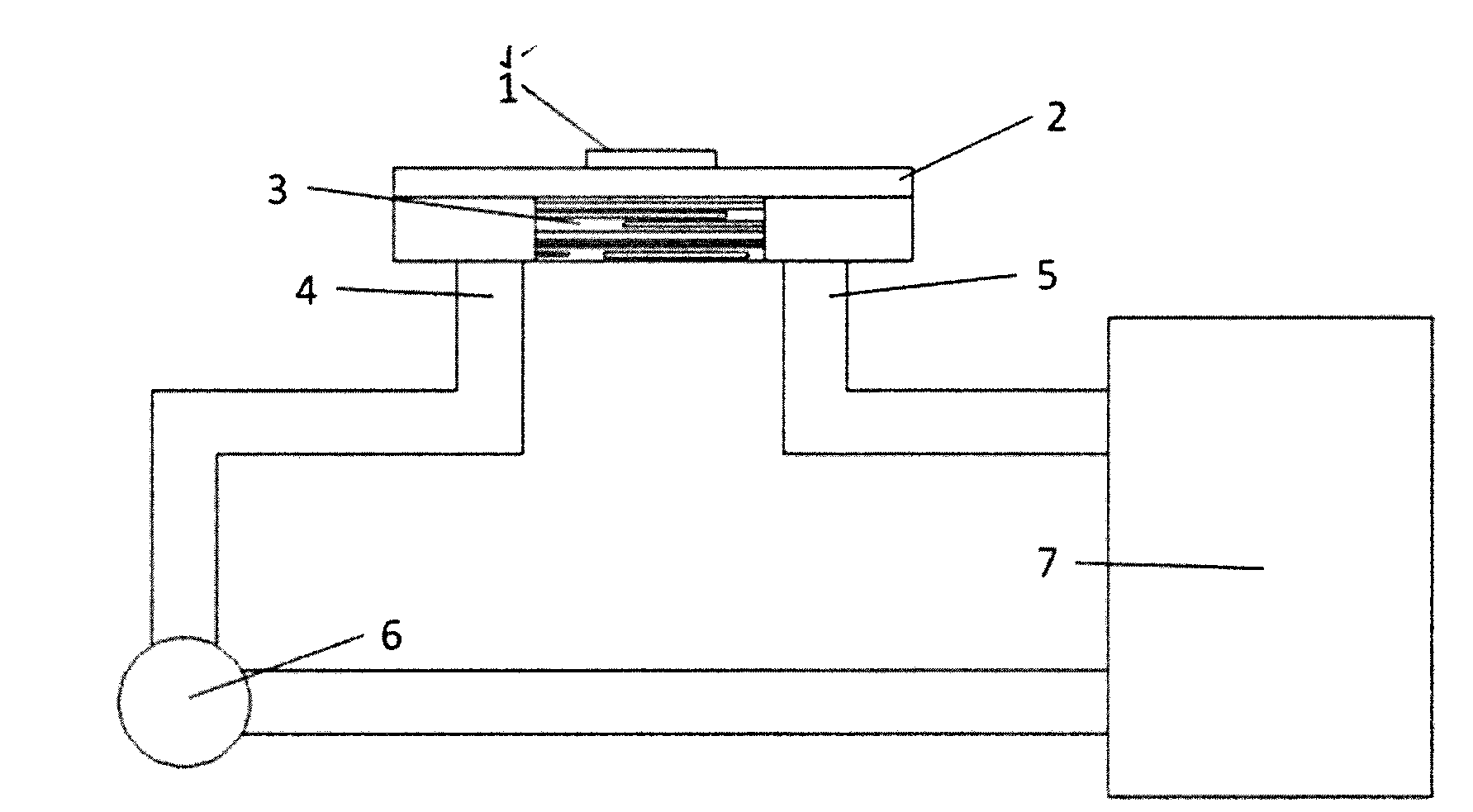

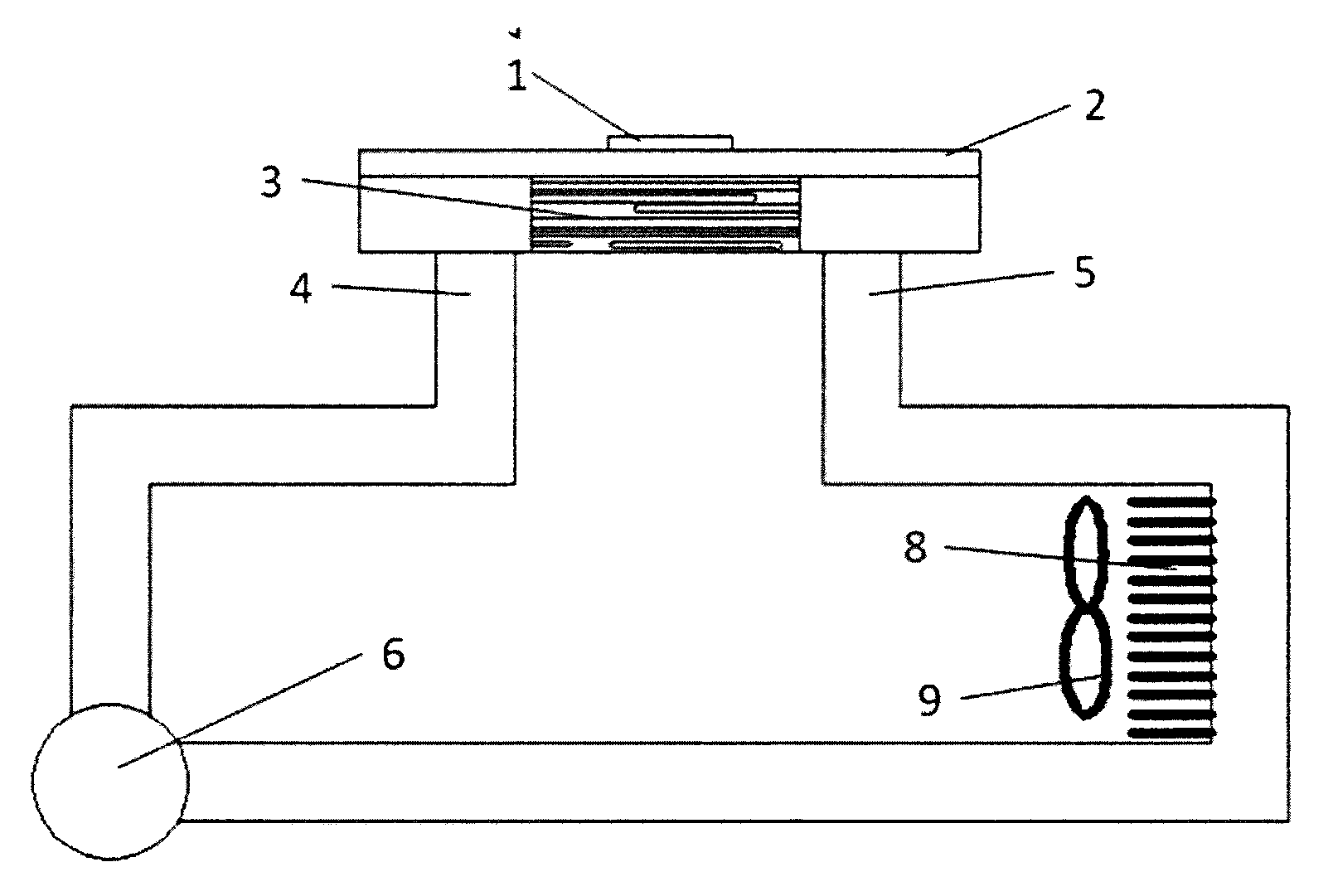

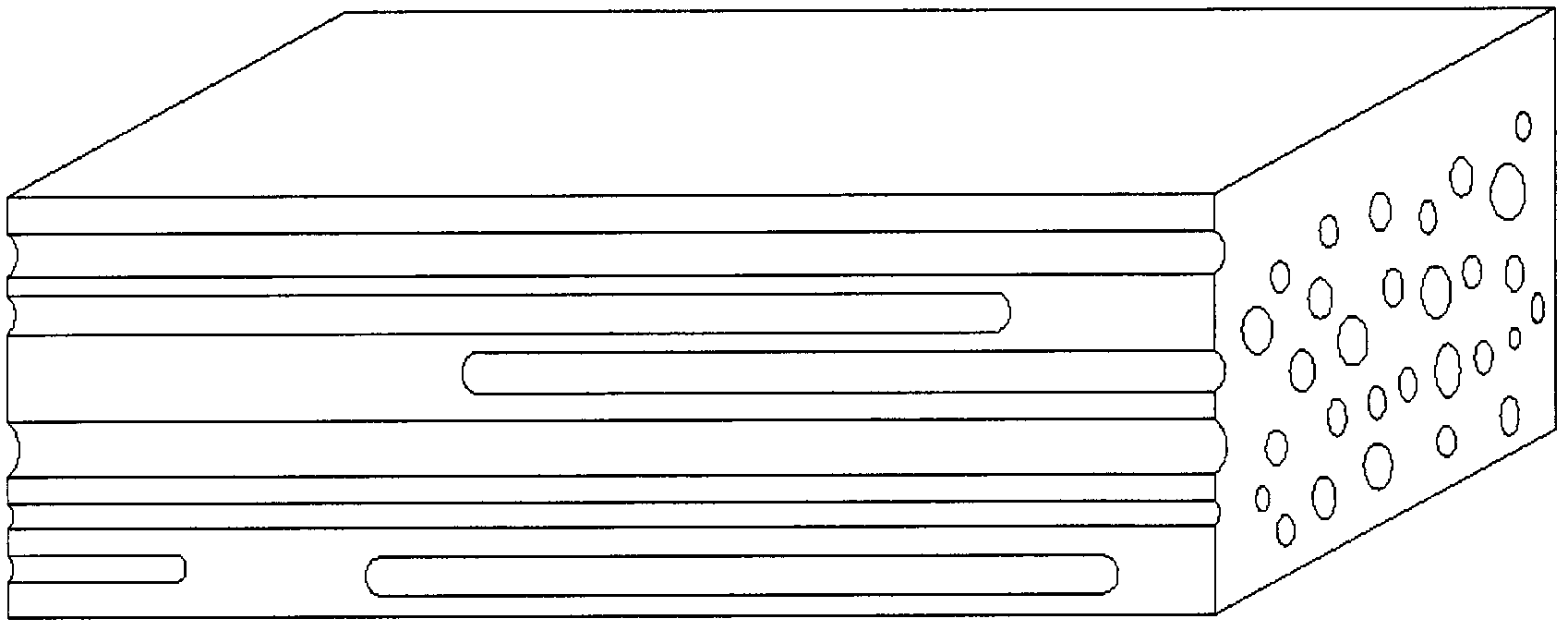

[0037] Such as figure 1 As shown, the electromagnetic pump 6, the liquid storage tank 7, and the microchannel module 3 are connected by pipelines to form a closed path, and the surface of the microchannel module 3 is connected to the copper cover plate 2 by diffusion welding, and is in contact with the chip 1 using thermal conductive silicone grease. To dissipate heat from the chip 1, the working medium liquid metal passes through the microchannel module 3 to take away the heat from the chip 1. The chip 1 can be a high heat flux electronic component chip or a semiconductor laser heating element, and flows to the liquid storage tank through the outlet 5 7. For remote heat dissipation, a cooling plate can be installed inside the liquid storage tank 7 to facilitate heat dissipation. The working medium flows through the liquid storage tank 7 and then enters the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com