Integrated cooling device of silicon-based micro-channel radiator

A cooling device and micro-channel technology, which is applied in electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of silicon-based micro-channel heat dissipation technology patents, etc., and achieve good expansion coefficient matching and heat dissipation efficiency. Increased, versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

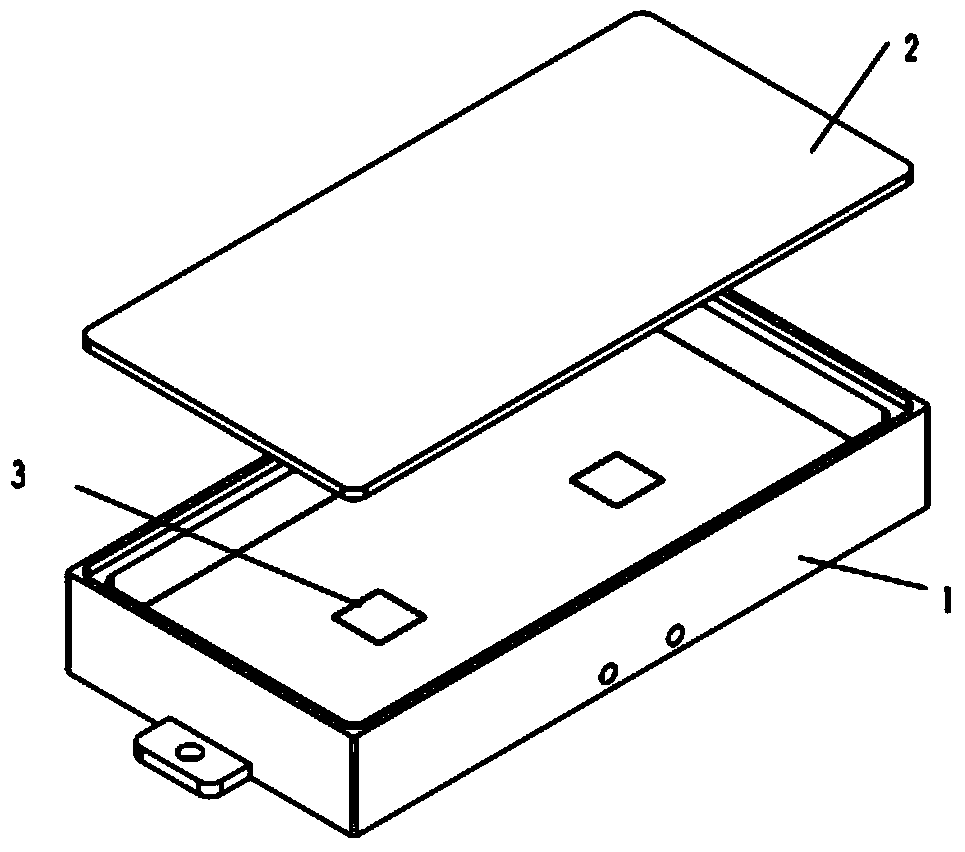

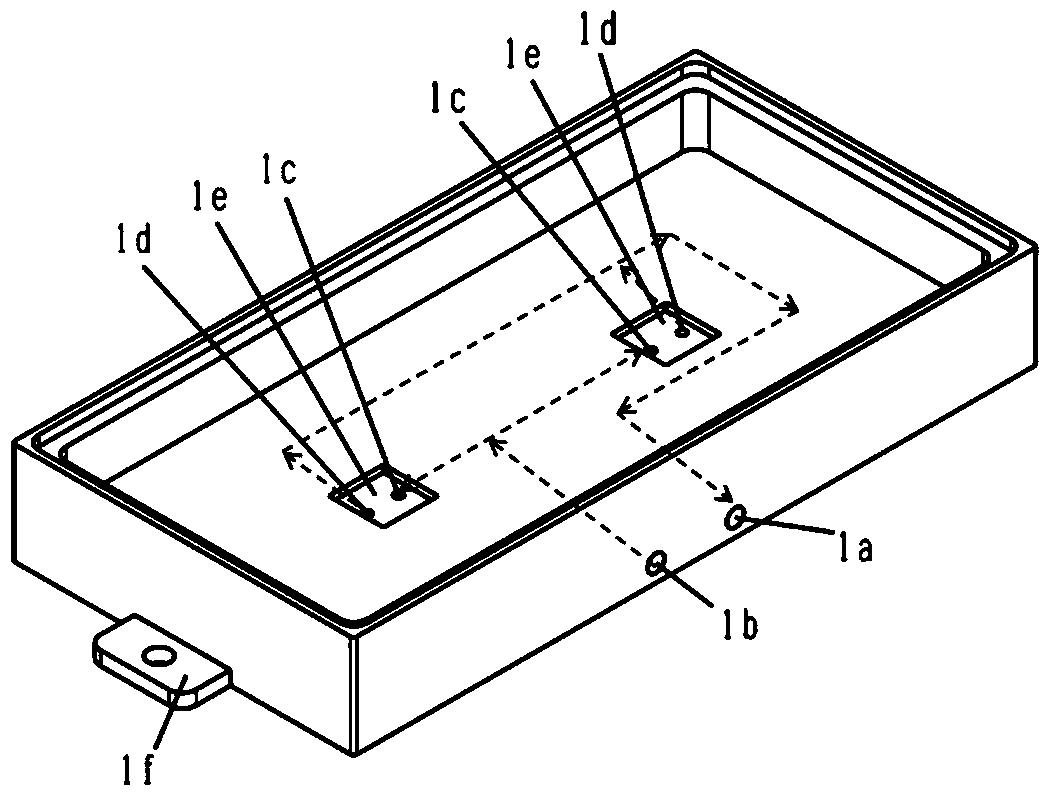

[0024] Such as figure 1 As shown, the peripheral dimensions of the silicon-based microchannel radiator integrated cooling device in this embodiment are 50mm (length) × 50mm (width) × 20mm (height), consisting of a box body, a silicon-based microchannel radiator, and a cover plate three Partial composition. The box body is a cavity with an open upper end, a flow channel is arranged inside the bottom plate of the box body, the inlet and outlet of the unit cooling liquid and the external opening of the internal electronic chip are arranged on the outer side of the box body, and mounting ears are arranged on the outer side of the box body for integrated cooling. External connection of the device.

[0025] Four small grooves are set on the bottom plate of the box body, and the silicon-based micro-channel radiator is installed in the small groove. The road is connected. The flow channel at the bottom of the box distributes the cooling liquid to the inlet of each silicon-based mic...

Embodiment 2

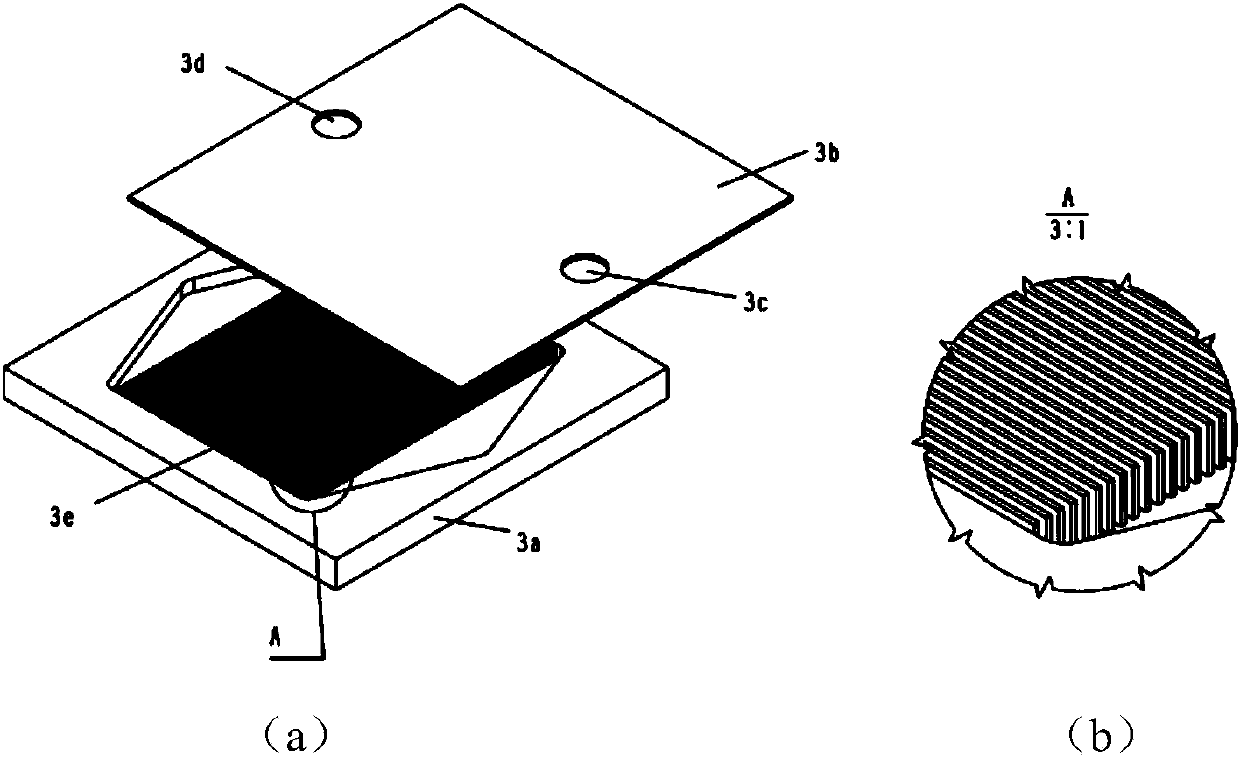

[0040] Such as figure 2 As shown, the peripheral dimension of the silicon-based microchannel radiator integrated cooling device is φ80mm×20mm, the size of the silicon-based microchannel radiator is 10mm×10mm×1.3mm, the flow channel is linear, the fin thickness is 0.08mm, and the fin The spacing is 0.06mm, and the inlet and outlet are round holes with a diameter of 1.2mm. The heat dissipation system is equipped with 4 silicon-based microchannel radiators. The cooling liquid inlet and outlet interface of the system is M3×0.35mm in size, located at the bottom of the device, and the diameter of the internal flow channel is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com