Micro-channel radiator with disturbed flow structures in horizontal and vertical directions

A vertical and horizontal technology, applied in the manufacture of electric solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve the problems of not improving the uniformity of the fluid temperature field, achieve good reproducibility, feasible preparation process, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

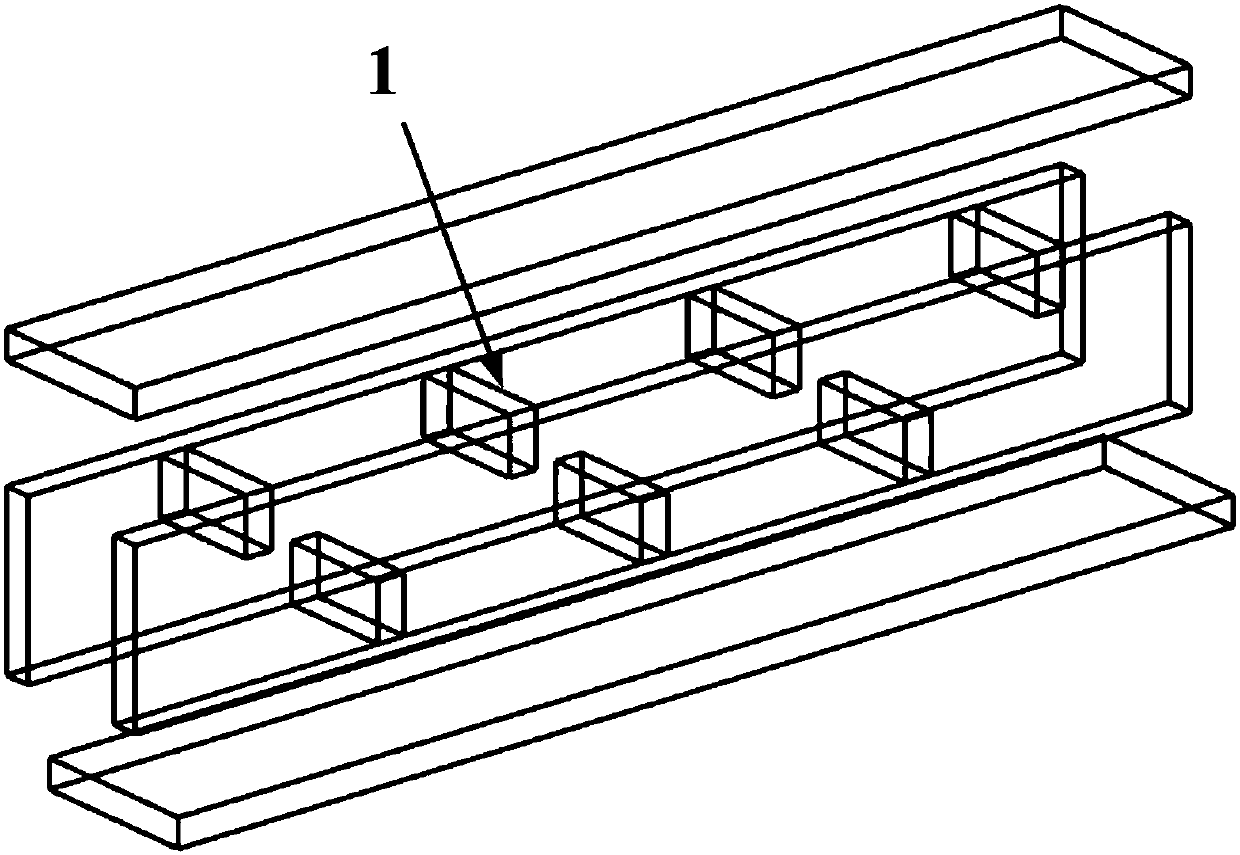

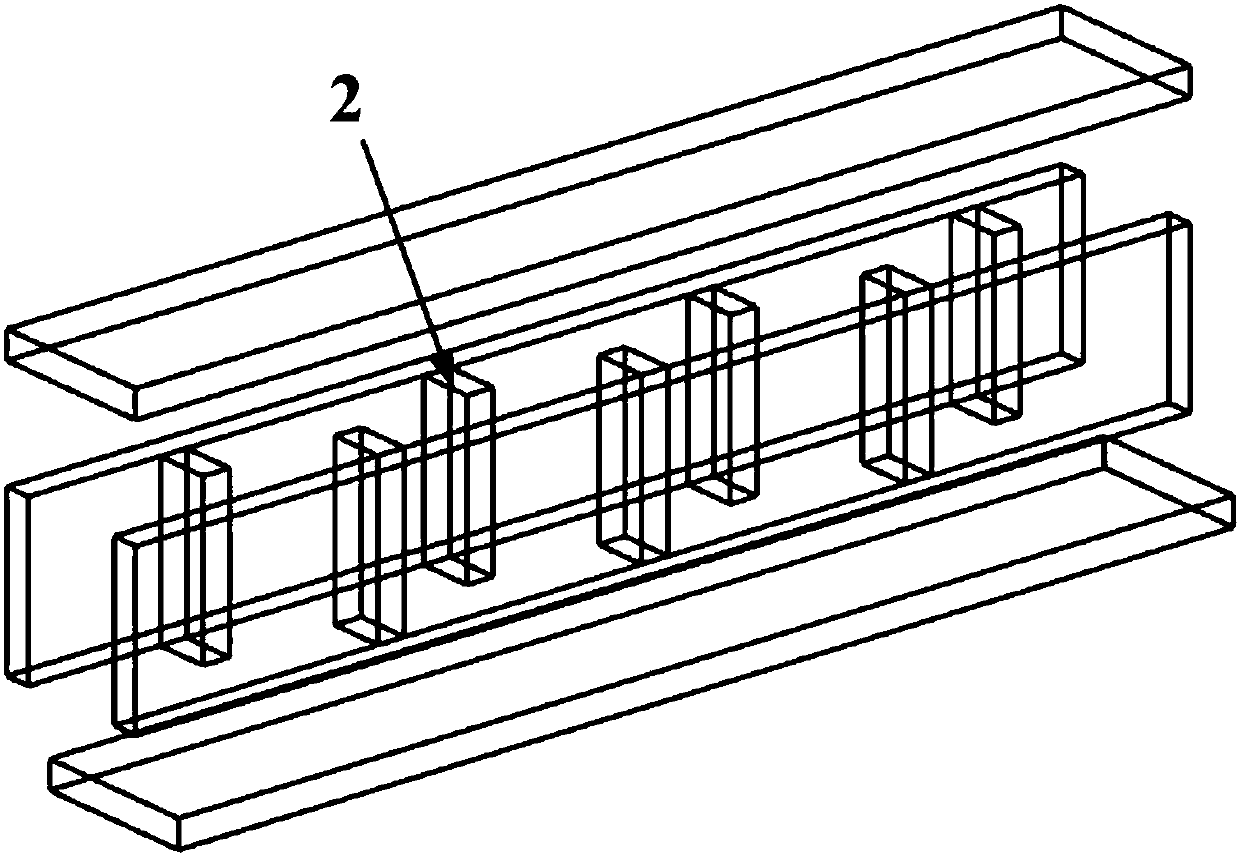

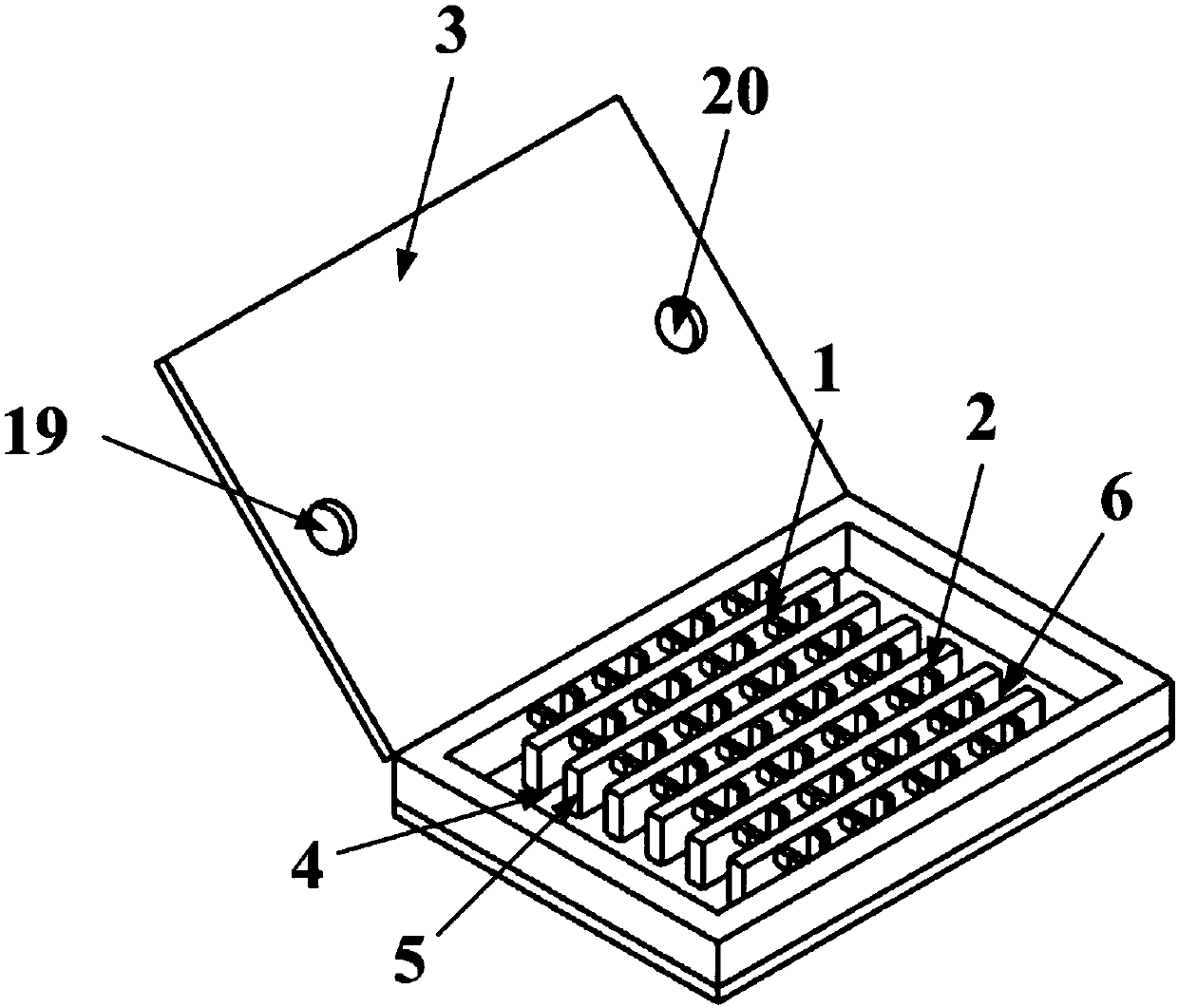

[0023] according to image 3 Shown is a horizontal direction and a micro-channel radiator with a horizontal and vertical spoiler structure, the lower surface of the upper cover plate of the micro-channel radiator is an upper wall surface, and the upper wall surface is provided with an inlet and an outlet of a heat dissipation medium. The left and right sides of the microchannel part are the left wall and the right wall, and the upper surface of the base part is the lower wall; three or four walls in the microchannel radiator are provided with turbulence structures, and the turbulence on the upper wall and the lower wall The structures are arranged in a staggered manner to enhance heat dissipation in the vertical direction; the spoiler structures on the left wall and the right wall are arranged in a staggered manner to enhance heat dissipation in the hor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com