Steady-state method-based heat conductivity coefficient measurement device

A technology of thermal conductivity and measuring device, which is applied in the field of measuring devices for measuring thermal conductivity of materials by steady-state method, can solve the problems of reducing measurement accuracy, temperature measurement uncertainty error, poor consistency of measurement data, etc., so as to reduce measurement error. , Improve the measurement accuracy, the results are consistent and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

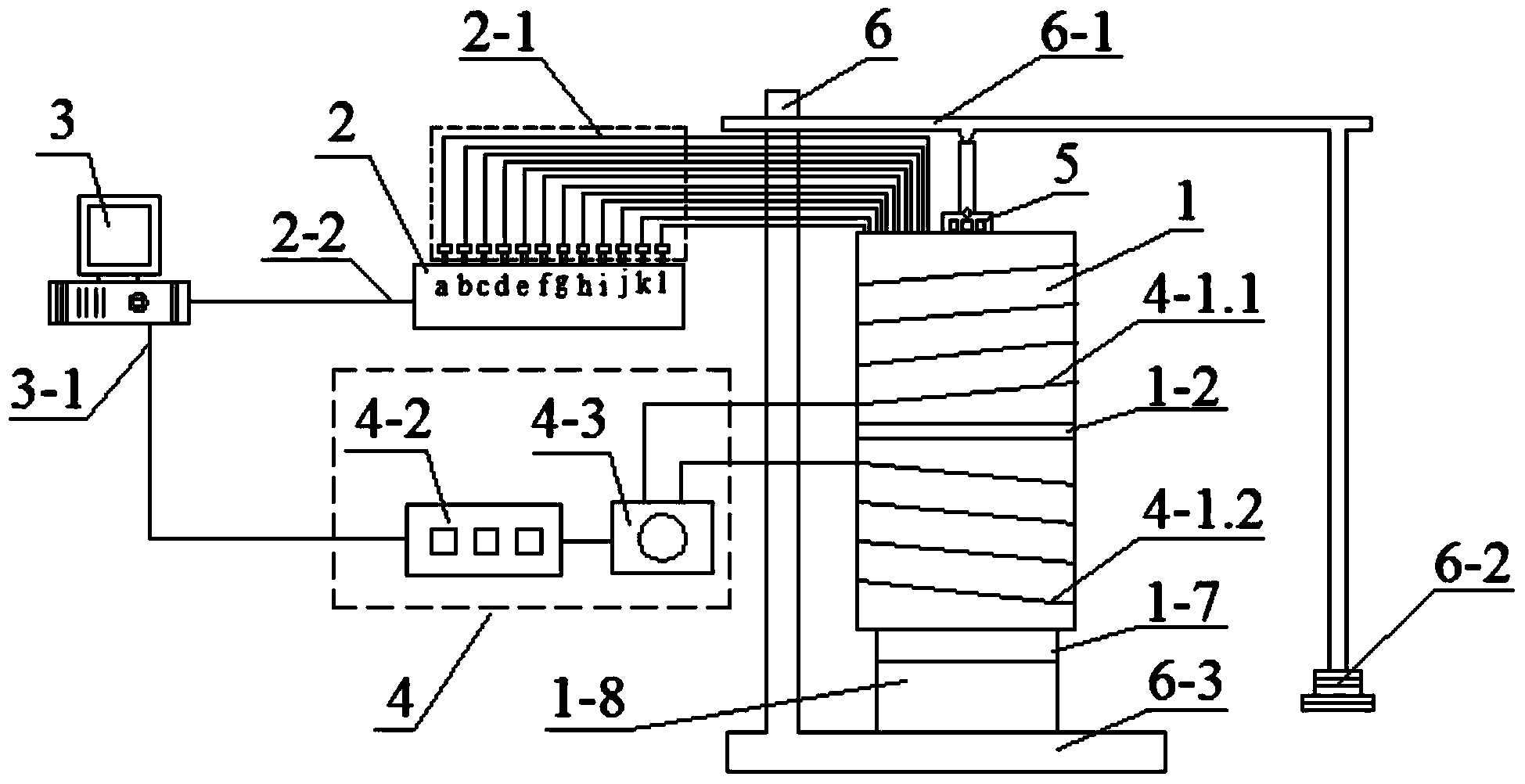

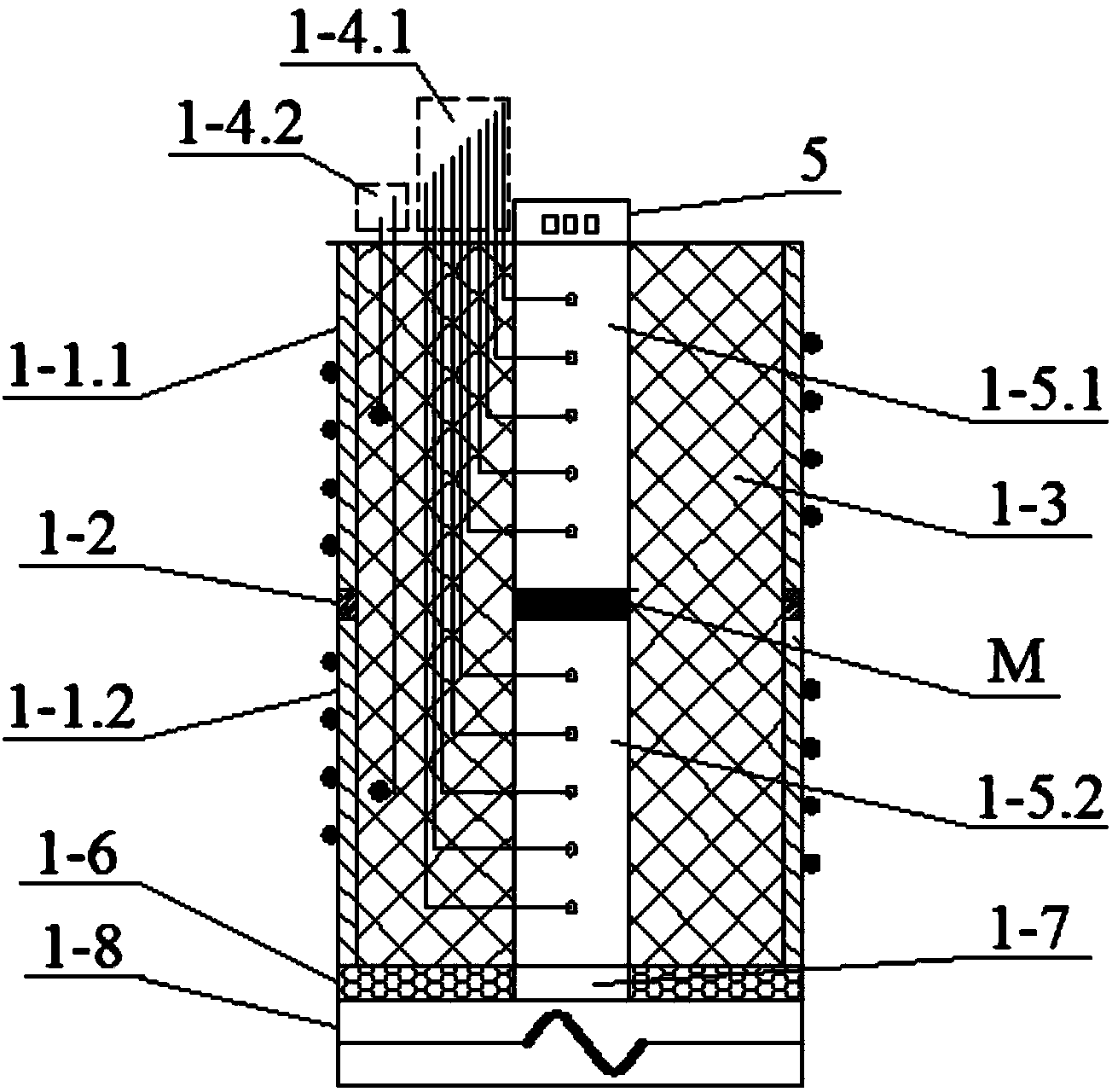

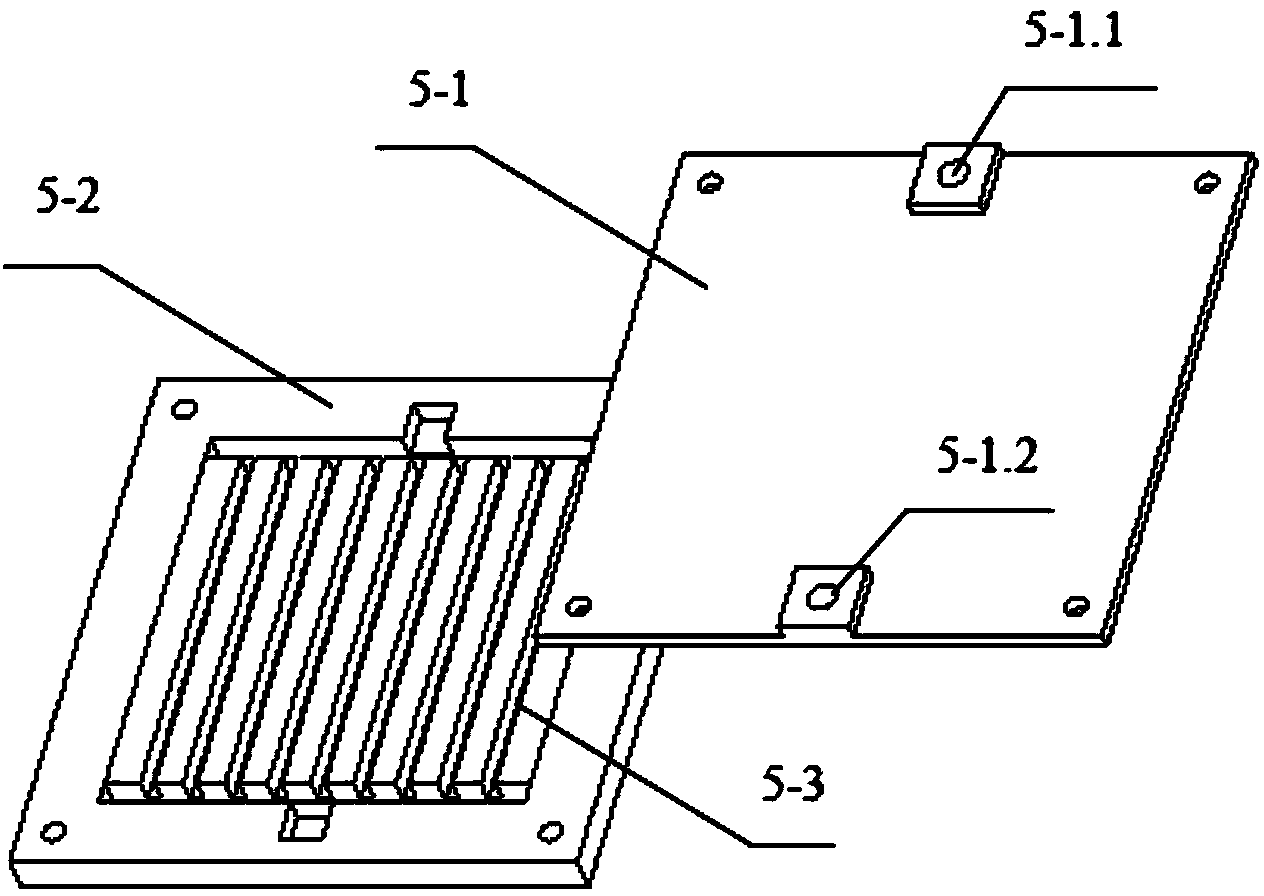

[0015] In this embodiment, the main heater 1-8 adopts an electric furnace, and the vapor chamber 1-7 is made of pure copper, surrounded by hard foam 1-6 as a heat insulation layer; the upper and lower standard test pieces 1-5.1 and 1-5.2 are implemented in this embodiment. The method adopts pure aluminum with a thermal conductivity of 237W / (K m), which are all cylinders with a diameter of Φ25mm and an axial height of 60mm. On each of them, 5 holes with a diameter of Φ1.1mm are drilled at a small interval of 10mm and a depth of 12.5mm. A small hole with a diameter of about 1.1mm and a depth of 12.5mm, with a pitch of 10mm, is used as a fixing hole for the thermocouple 1-4.1, and the thermocouple 1-4.2 is provided in the middle of the upper and lower shells at a distance of 5mm from the inner wall of the shell. 1-4.1 and 1-4.2 all use armored K-type thermocouple WRNK-191, with a diameter of 1mm, capable of measuring the temperature range of 0-1100°C, and each thermocouple is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com