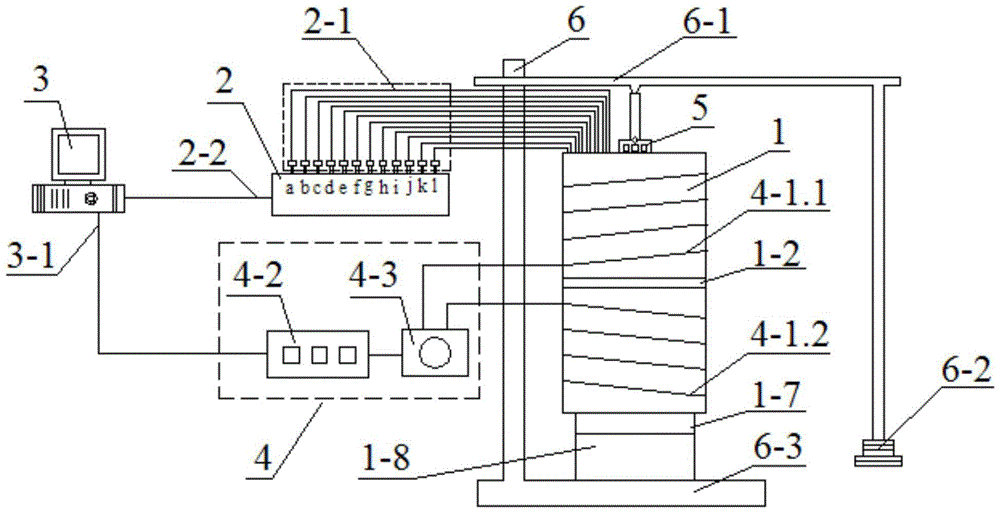

A thermal conductivity measurement device based on steady state method

A thermal conductivity and measuring device technology, which is applied in the field of measuring devices for measuring thermal conductivity of materials by a steady-state method, can solve problems such as temperature measurement uncertainty errors, reduce measurement accuracy, and affect measurement accuracy, so as to improve measurement accuracy, The effect of reducing measurement error and avoiding lateral loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

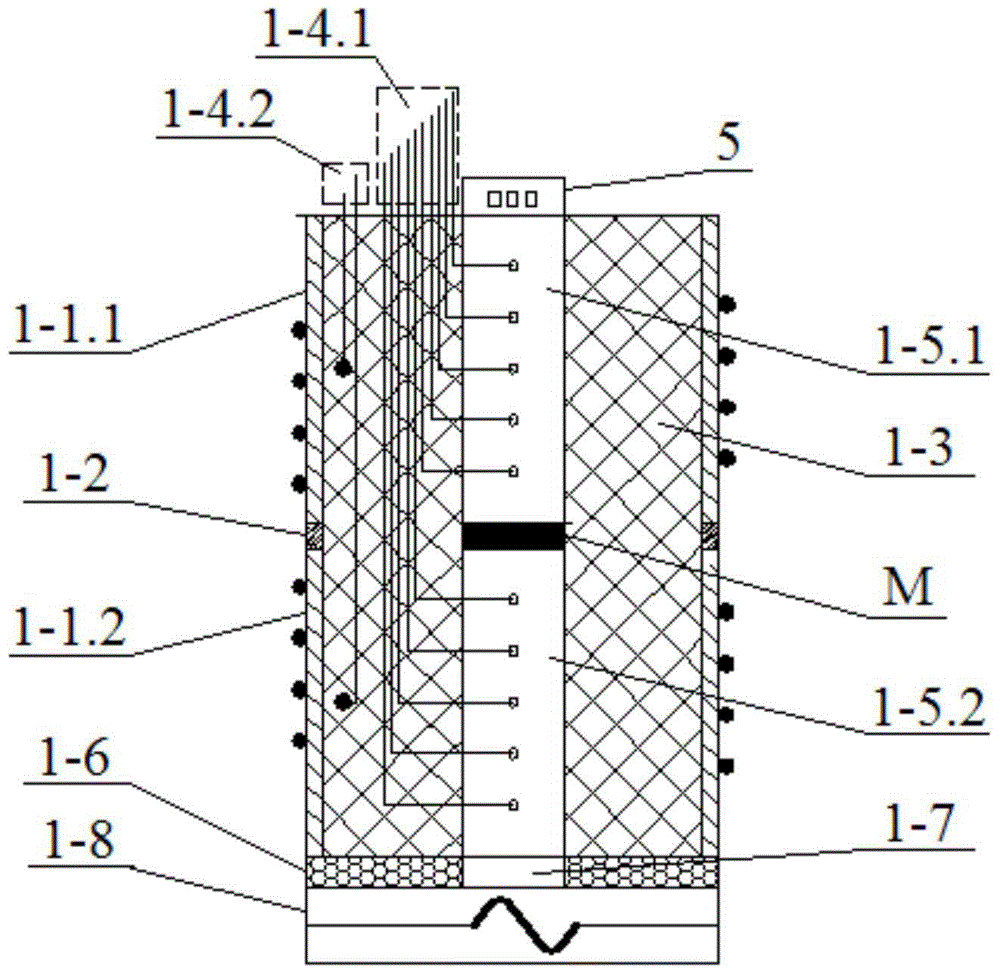

Embodiment Construction

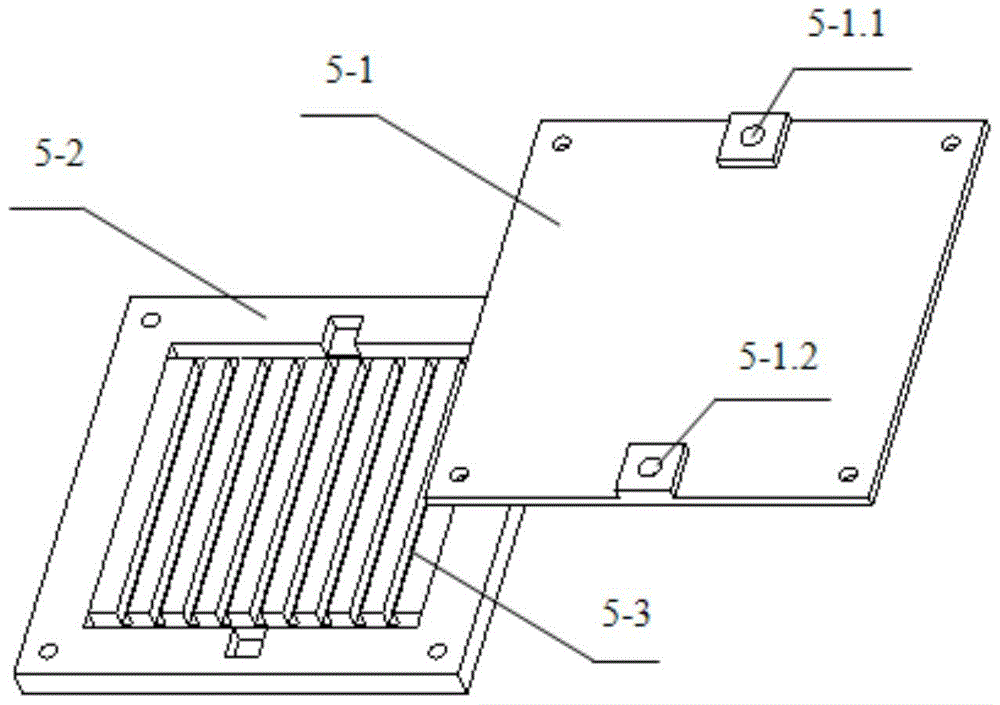

[0016] In this embodiment, the main heater 1-8 adopts an electric furnace, and the vapor chamber 1-7 is made of pure copper, surrounded by hard foam 1-6 as a heat insulation layer; the upper and lower standard test pieces 1-5.1 and 1-5.2 are implemented in this embodiment. The method adopts pure aluminum with a thermal conductivity of 237W / (K m), which are all cylinders with a diameter of Φ25mm and an axial height of 60mm. On each of them, 5 holes with a diameter of Φ1.1mm are drilled at a small interval of 10mm and a depth of 12.5mm. A small hole with a diameter of about 1.1mm and a depth of 12.5mm, with a pitch of 10mm, is used as a fixing hole for the thermocouple 1-4.1, and the thermocouple 1-4.2 is provided in the middle of the upper and lower shells at a distance of 5mm from the inner wall of the shell. 1-4.1 and 1-4.2 all use armored K-type thermocouple WRNK-191, with a diameter of 1mm, capable of measuring the temperature range of 0-1100°C, and each thermocouple is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com