Enhanced heat dissipation device with pulsating flows and wavy-wall microchannels adopted

A technology of heat dissipation device and micro-channel, applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of uneven temperature distribution, low heat dissipation capacity, high pumping power, etc., and achieve high heat exchange efficiency and contact area. Increase and ensure the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

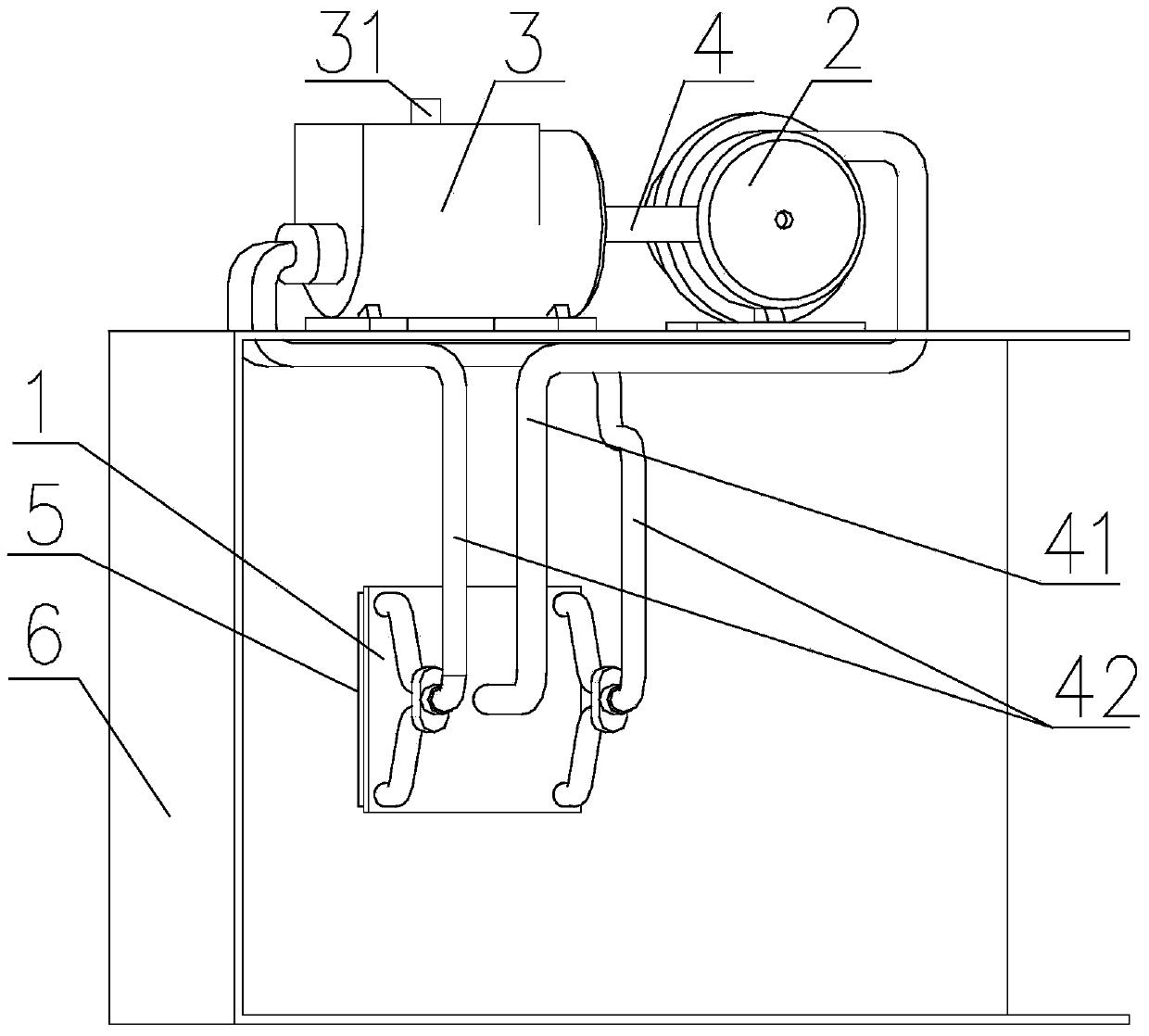

[0028] In this example, the structure of the cooling device is as follows: figure 1As shown, it is mainly composed of four major parts: a microchannel heat dissipation cold plate 1, a pulsation pump 2, a circulating water cooler 3 and a pipe 4 connecting them. The cooling device is evacuated from the sealing port 31 and filled with a certain volume of water or other liquid working medium, and then sealed. The pulsating flow generated by the pulsating pump 2 enters the micro-channel radiating cold plate 1 through the injection pipe 41 connecting the micro-channel radiating cold plate 1 and the pulsating pump 2, and the heat generated by the CPU 5 is absorbed by the micro-channel radiating cold plate 1 through conduction, and is then absorbed by the micro-channel radiating cold plate 1. The liquid working medium flowing through the microchannel heat dissipation cold plate 1 is brought into the circulating water cooler 3 through the return pipe 42 connecting the microchannel heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com