Radiating system

A heat dissipation system and heat dissipation device technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of reducing the ratio of heat exchange to pump power, maximizing heat exchange and reducing heat exchange economy, etc. Achieve high heat transfer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The system, local structure and technical details of the present invention will be further described in detail below in conjunction with the accompanying drawings.

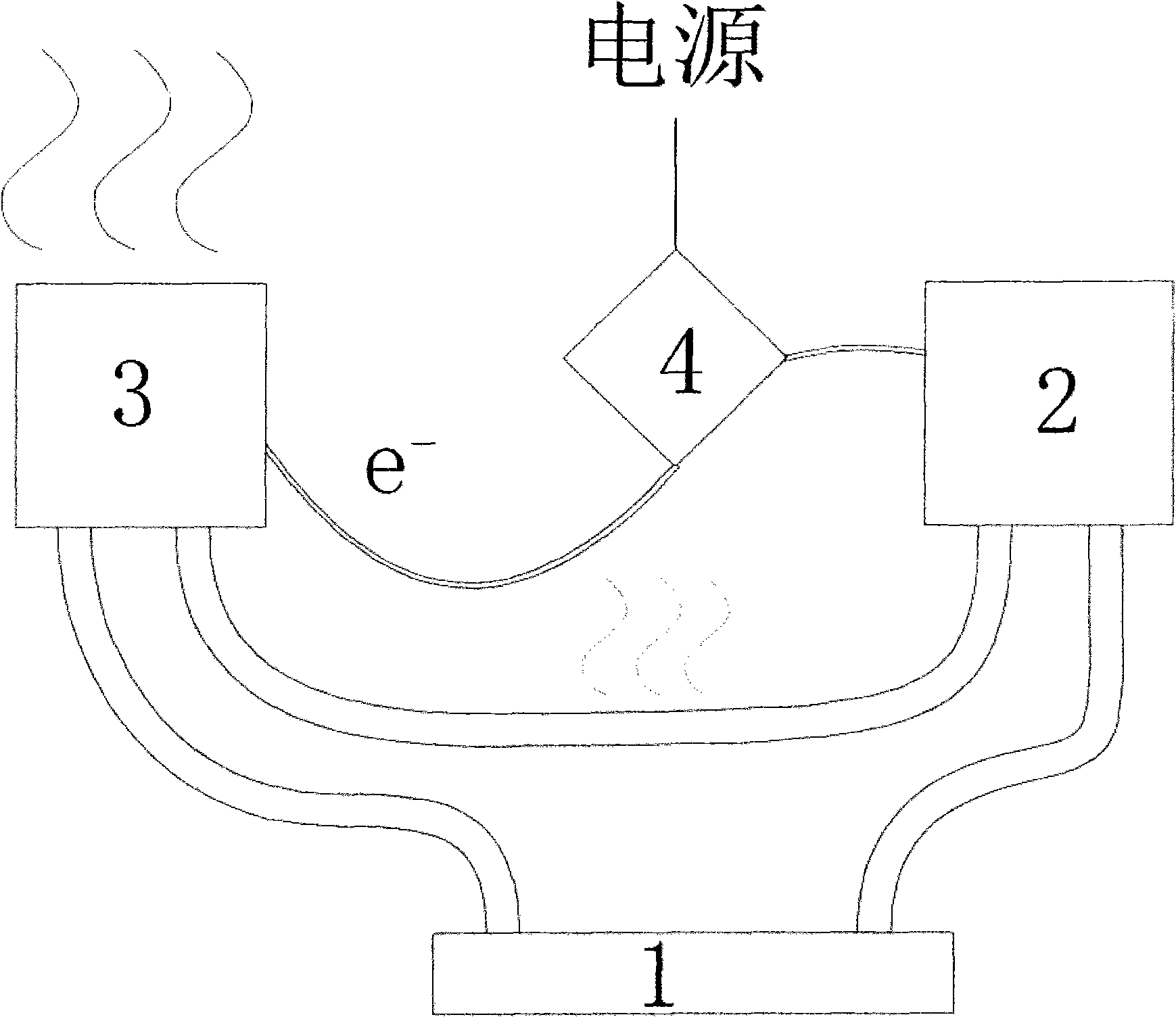

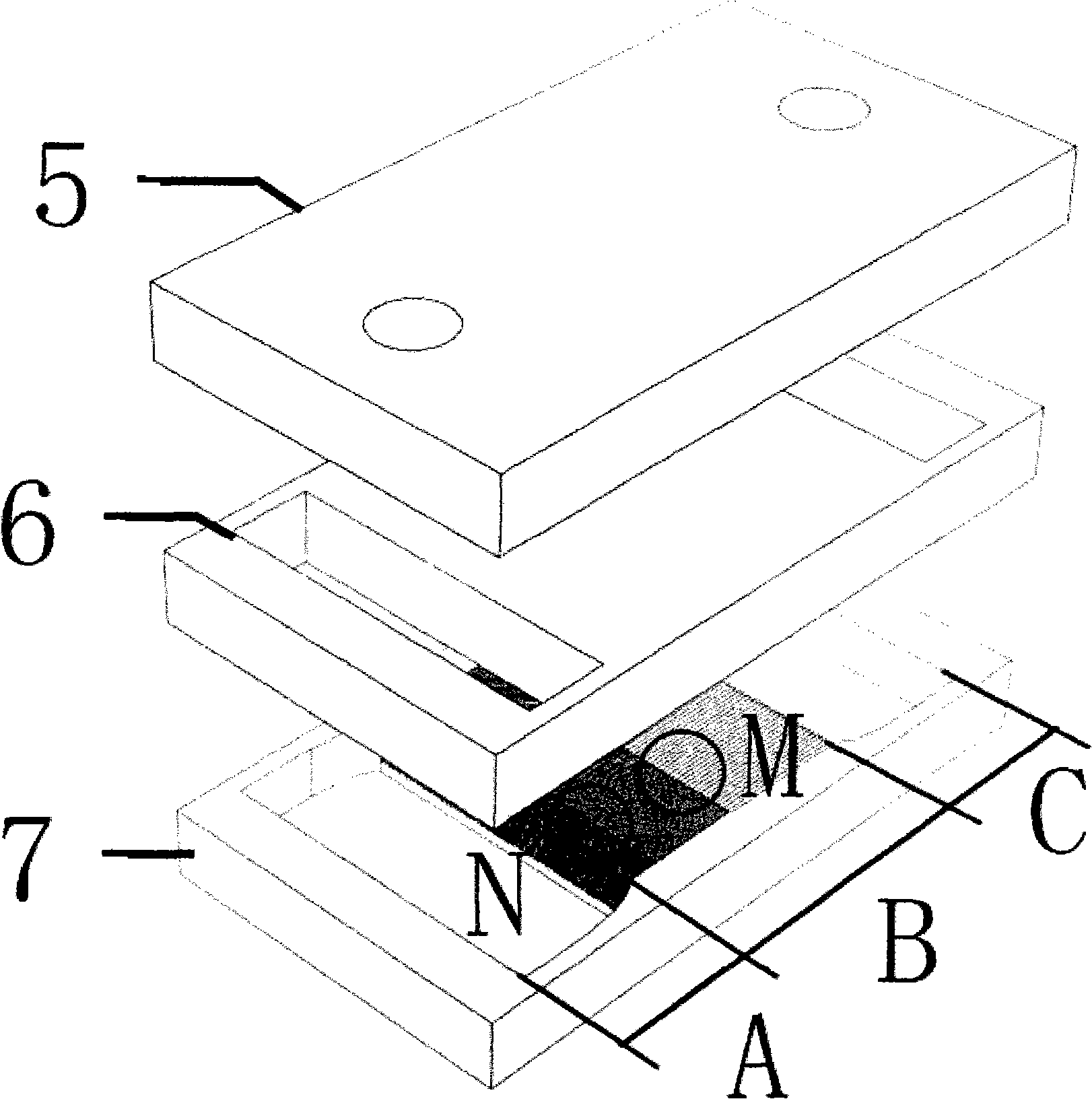

[0031] figure 1 is a schematic diagram of the cooling system of the present invention, as figure 1 As shown, the entire heat dissipation system consists of a microchannel heat sink system 1 , a micropump device 2 , a power supply system 3 and a power supply device 4 to form a self-circulating system. The working fluid cools the heat-generating components in the micro-channel heat sink system 1. The high-temperature working fluid flows out of the micro-channel heat sink system 1 and then enters the power supply system 3. The thermoelectric components made of thermoelectric materials use the temperature difference between the working fluid and the environment to generate electricity. , the auxiliary power supply device 4 provides energy to the micropump device 2, and the driving force of the working fluid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com