Complex heat pipe controller, and its manufacturing method and use

A thermal controller and thermal control technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0296] Embodiment 1. Solar flower heat pipe thermal controller

[0297] Figure 25 The heat source 1 is a computer CPU, the shell of the heat pipe 2 has a cylindrical cross-section, and the fins are fork-knife-shaped fins 4 made of aluminum. The heat pipe fins are formed by extruding aluminum. After the end is sealed, it is produced into a heat pipe, which becomes the Sunflower heat pipe heat controller;

[0298] Embodiment 2. Triangular arc-fin thermal controller

[0299] Figure 26 The heat source 1 is a computer CPU, the shell of the heat pipe 2 has a triangular cross-section, and the fins are arc-shaped flat fins 5 made of aluminum. The metal sheets are welded to each other;

Embodiment 3

[0300] Embodiment 3. Cylindrical plate-fin thermal controller

[0301] Figure 27 The heat source 1 is a semiconductor cooling chip, the shell of the heat pipe 2 has a cylindrical section, and the fins are flat fins 6 made of aluminum. The heat pipe 2 is made by extruding aluminum, and the two ends of the heat pipe are closed to form a heat pipe. thermal controller;

Embodiment 4

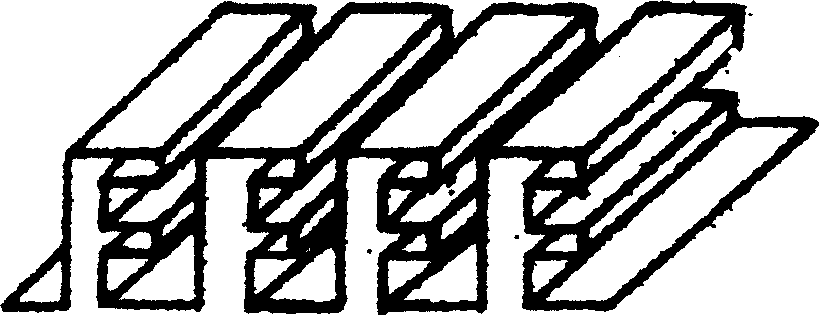

[0302] Embodiment 4, pin-fin copper tube heat controller

[0303] Figure 28 Among them, the heat source 1 is a computer CPU, the heat pipe 2 shell section is cylindrical, the fins are pin-fin fins 7, and the material is copper. The sealant 12 is sealed to make a heat pipe heat controller;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com