Soft magnetic composite material of collosol infiltrating glass powder coating layer and preparation method of soft magnetic composite material

A technology of soft magnetic composite materials and glass powder, which is applied in the direction of the magnetism of inorganic materials, and can solve the problems of large differences in thermal expansion coefficients between inorganic insulating layers and magnetic powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

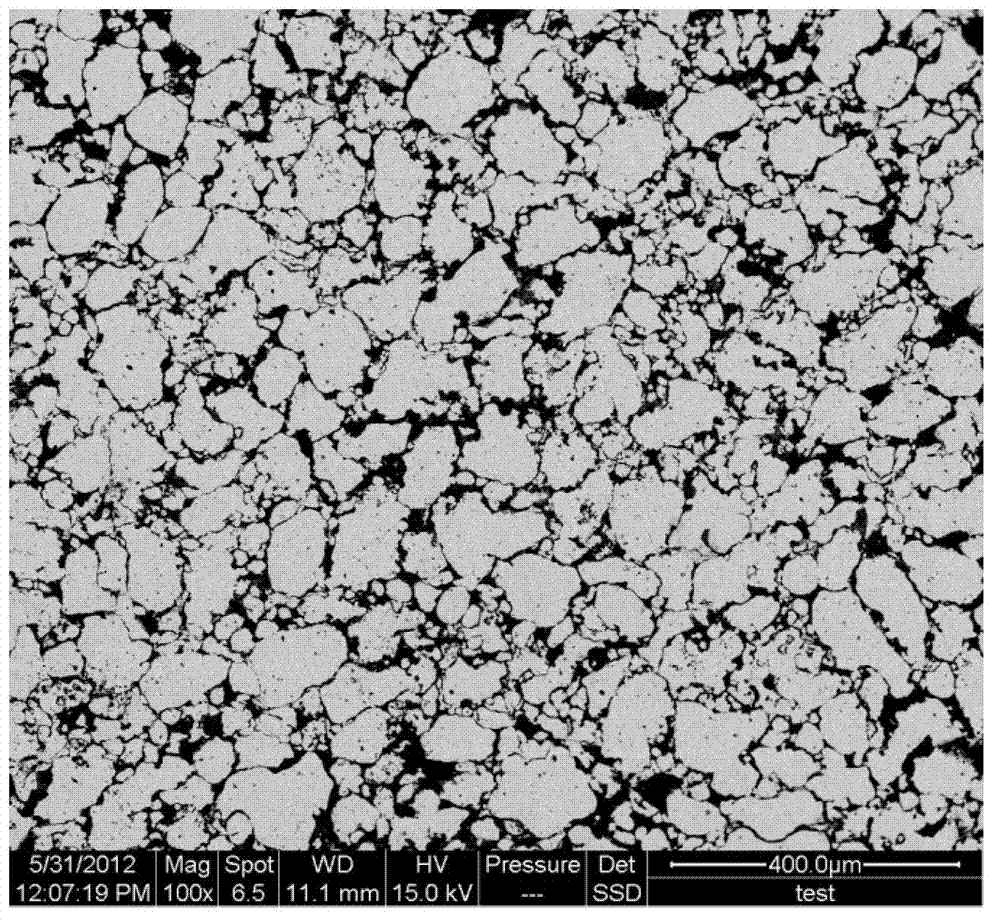

Image

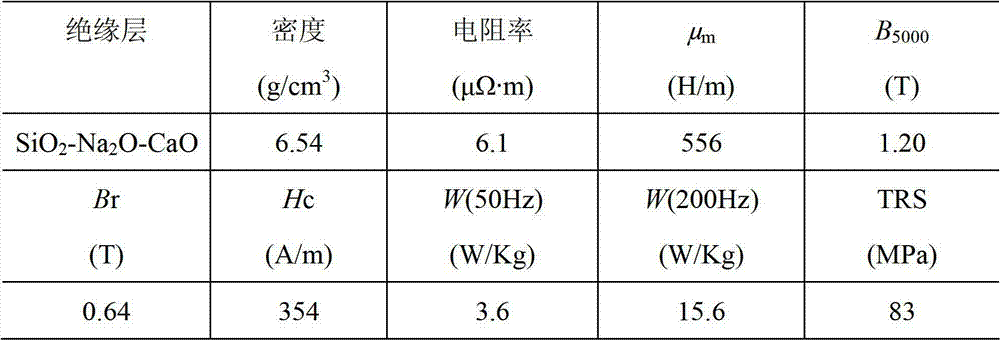

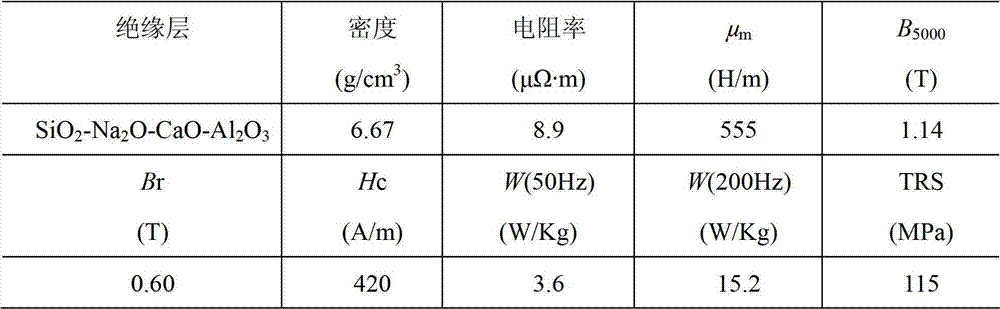

Examples

specific Embodiment approach 1

[0027] Embodiment 1: The soft magnetic composite material of the sol-infiltrated glass powder coating layer provided in this embodiment is composed of magnetic powder, a silicon dioxide layer coated with magnetic powder, a glass powder layer coated outside the silicon dioxide layer, and glass The composition of the sol impregnated layer; wherein, the magnetic powder is one or a combination of magnetic metal powder, magnetic metal alloy powder and magnetic metal compound powder.

[0028] The soft magnetic composite material of the sol-infiltrated glass frit coating layer provided in this embodiment can adjust the composition and proportion of the glass frit layer according to the coefficient of thermal expansion. The thermal expansion coefficients of the two substances in one material do not match, and internal stress is easily generated inside the material when the temperature changes, which in turn reduces the magnetic properties of the soft magnetic composite material. There...

specific Embodiment approach 2

[0031]Specific embodiment two: the difference between this embodiment and specific embodiment one is: the magnetic powder is Fe powder, Ni powder, Co powder, iron alloy powder, nickel alloy powder, cobalt alloy powder, iron-containing oxide powder, nickel-containing oxide One or a combination of powders and cobalt oxide powders are magnetic.

[0032] The iron alloy powder described in this embodiment is an alloy powder composed of iron element and one or more elements, and the mass fraction of iron is the largest, wherein the iron alloy powder can be Fe-Si-Al powder, Fe-Ni-Mo powder, Fe-Ni powder, Fe-Cu-Nb-Si-B powder, Fe-Pt powder, Fe-Ni-Cr powder, Fe-Zn powder, La-Co-Fe powder, Pb-Fe powder, W-Ni-Fe powder Powder and Zr-Ni-Sn-Fe powder or a combination of several of them.

[0033] The nickel alloy powder described in this embodiment is an alloy powder composed of nickel element and one or more elements, and the mass fraction of nickel is the largest, wherein the nickel allo...

specific Embodiment approach 3

[0035] Specific implementation mode three: the preparation method of the soft magnetic composite material of the sol-infiltrated glass frit coating layer provided in this implementation mode is specifically completed according to the following steps:

[0036] 1. Put the magnetic powder into the cleaning agent and ultrasonicate at a frequency of 24KHz~35KHz for 10min~20min, filter to obtain clean magnetic powder, add ethanol and oleic acid to the clean magnetic powder, and use 20%~30% ammonia water to dissolve the solution Adjust the pH value to 8.5-9.5, ultrasonically disperse at a frequency of 24KHz-35KHz for 1 hour-2 hours or stir at a speed of 600r / min-1200r / min for 1 hour-2 hours to obtain a solid-liquid mixture, in which oleic acid and The mass ratio of magnetic powder is (0.03~0.2):1, the volume ratio of oleic acid and ethanol is 1:(40~75), the magnetic powder is magnetic metal powder, magnetic metal alloy powder and magnetic metal compound powder one or a combination of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com