Near-zero expansion lattice structure

A lattice structure, near-zero expansion technology, applied in the aerospace field, can solve the problems of difficult processing and mass production, difficult to control, poor characteristics, etc., to achieve easy engineering practical application, adjustable thermal expansion coefficient, simple structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]This embodiment discloses a near-zero expansion lattice structure:

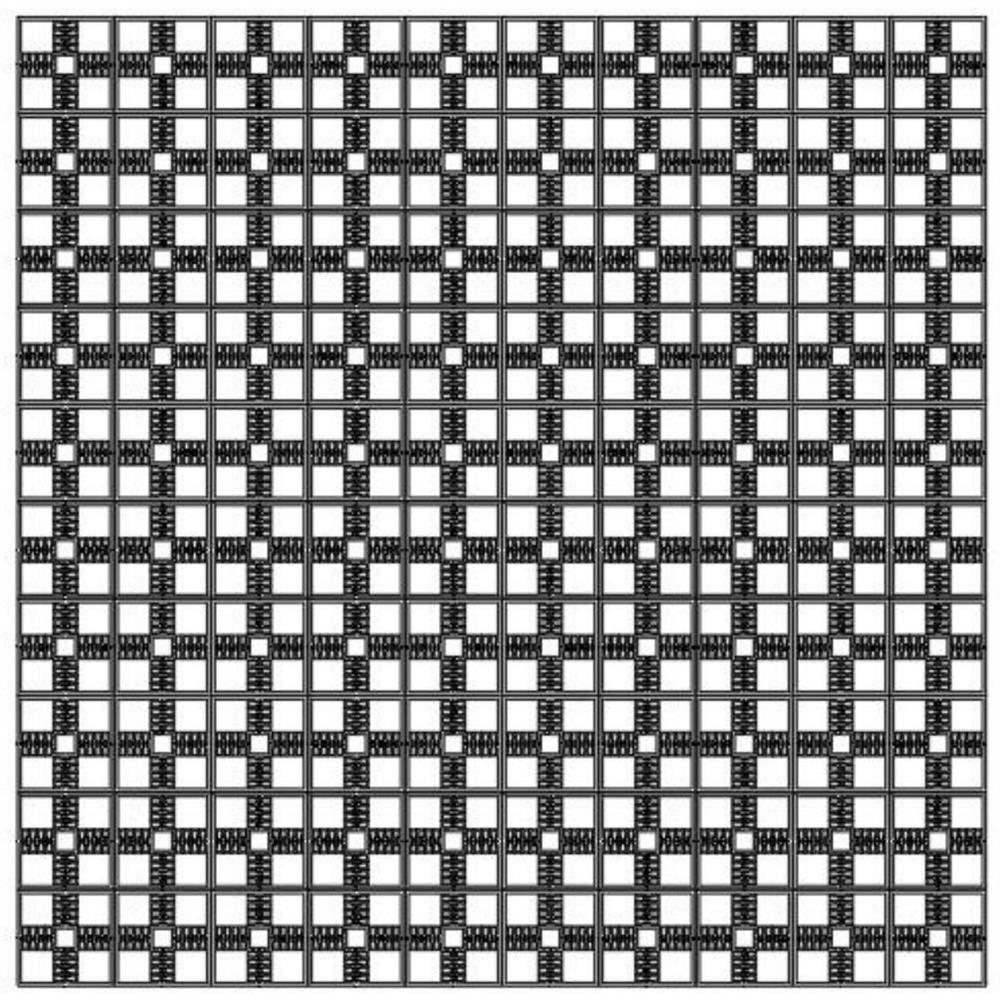

[0053] 1) A near-zero-expansion lattice structure, through the regular shape of the unit cell through such as Figure 5 The contact points 5 shown are arranged and connected, and the overall arrangement effect is as follows figure 1 shown;

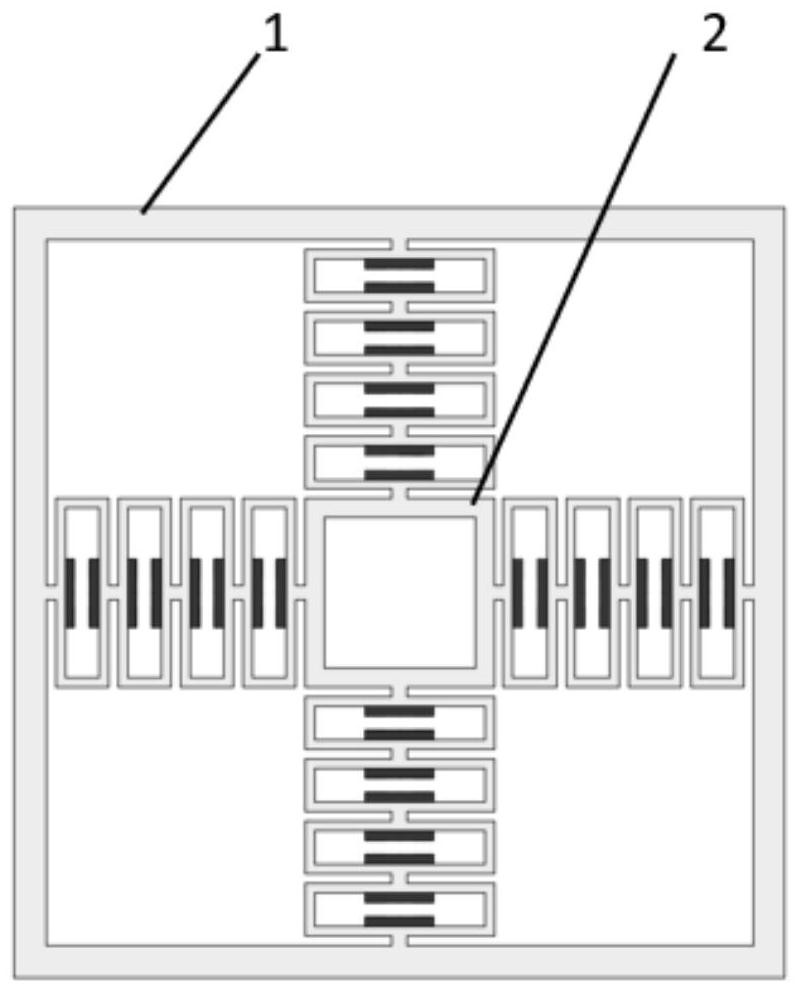

[0054] 2) The unit cell includes an inner frame 2, a microstructure and an outer frame 1; the inner frame 2 and the outer frame 1 are centrosymmetric structures; the plurality of microstructures are fixed outside the inner frame 2 in a centrosymmetric manner; the The outer frame 1 places the inner frame 2 and the microstructure in it, and the unit cell structure is as follows figure 2 shown;

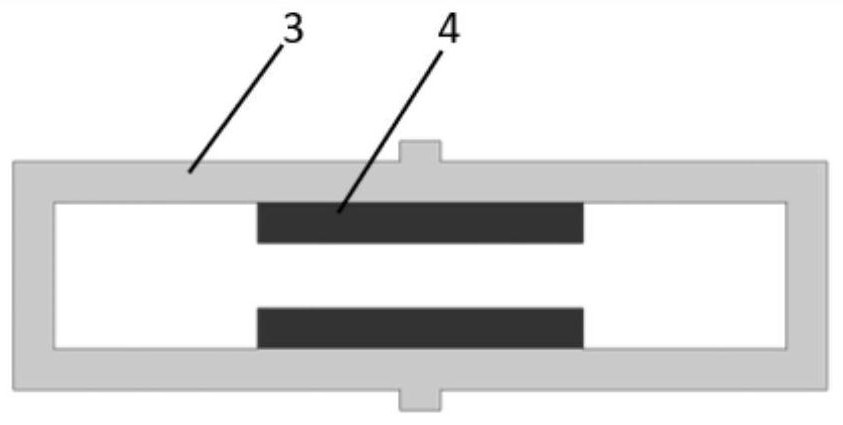

[0055] 3) if image 3 As shown, the microstructure is composed of a fixed load-bearing side 3 and a dynamic adjustment side 4; the fixed load-bearing side 3 is a symmetrical structure, and it is necessary to ensure that every two fixed load-bearing sides 3 are connected ...

Embodiment 2

[0061] Keep 1)~3) steps in Example 1 unchanged, get L Actuation =11mm, W R,outer Taking it as 5.5mm, and bringing the set parameters into equations (1) to (7), the linear expansion coefficient of the microstructure is calculated to be -29.8ppm. Then bring the linear expansion coefficient of the microstructure into the overall structure for simulation, and the measured linear expansion coefficient of the unit cell structure is 0.38ppm.

Embodiment 3

[0063] Keep 1)~3) steps in Example 1 unchanged, get L Actuation =13mm, W R,outer Taking it as 6.9mm, and bringing the set parameters into equations (1)~(7), the linear expansion coefficient of the microstructure is calculated to be -36.5ppm. Then bring the linear expansion coefficient of the microstructure into the overall structure for simulation, and the measured linear expansion coefficient of the unit cell structure is 0.46ppm.

[0064] In the above embodiments, the measured linear expansion coefficients of the unit cell structures are 0.23, 0.38 and 0.46, respectively. This shows that the regular arrangement of the cell junctions is as follows figure 1 For the lattice structure shown, the deformation is only 0.023mm / m, 0.038mm / m and 0.046mm / m when the temperature difference is 100 degrees Celsius. This shows that in an extreme environment, even when encountering a huge temperature difference due to environmental changes, the overall deformation of the structural parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com