Method for preparing polyimide film

A technology of polyimide film and polyamic acid, which is applied in the field of preparing polyimide film, can solve the problems of inability to obtain polyimide film conveniently, different thermal expansion coefficients, deformation and curling, etc., and achieve outstanding mechanical properties and High-temperature use performance, excellent performance, and the effect of improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

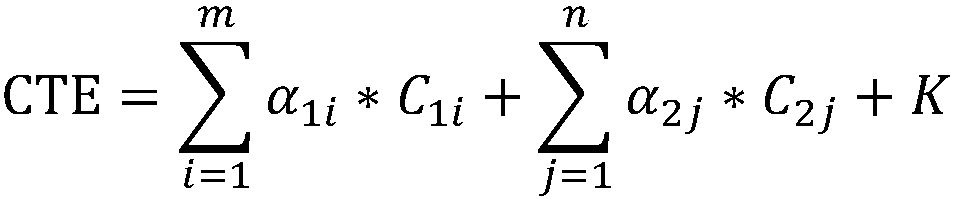

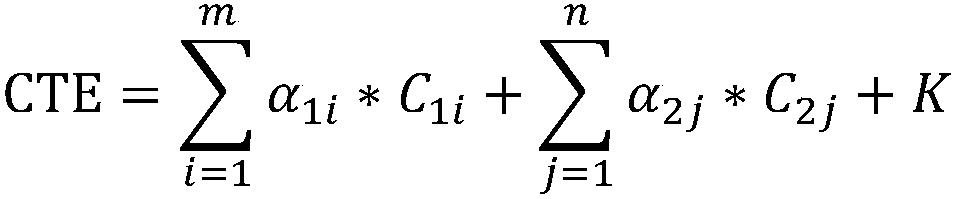

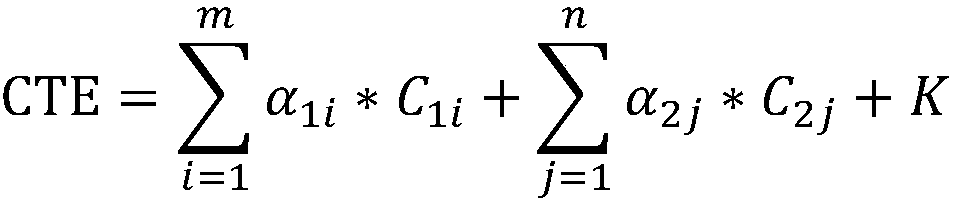

[0080] (1) According to the CTE of the matched Ni metal substrate (shown in Table 4), take 0.1mol of 4,4'-diaminobenzanilide and 0.06mol of pyromellitic dianhydride and 0.04mol of 3 , 3',4,4'-diphenyl ether dianhydride, reacted in a DMAc solvent at 0°C, the solid content of the obtained polyamic acid solution was 12wt%, and the intrinsic viscosity was 1.8dl / g;

[0081] (2) Cast the solution prepared in step (1) into a film under the condition of 25° C., the carrier is a glass plate, and dry it in a drying oven at 60° C. for 6 hours;

[0082] (3) Put the film and carrier obtained in step (2) into the electric heating blower, heat up at 3°C / min, and keep warm at 135°C, 300°C, and 350°C for 2 hours each, and cool naturally after the program ends;

[0083] (4) Put the film and carrier through step (3) into boiling water for 10 minutes to remove the film;

[0084] (5) Put the film after step (4) into a drying oven, keep at 200° C. for 10 min to remove moisture to prepare the polyi...

Embodiment 2

[0086] (1) According to the CTE of the matched Cu metal substrate (shown in Table 4), take 0.06mol of 4,4'-diaminobenzanilide, 0.04mol of p-phenylenediamine and 0.06mol of pyromellitic Formic acid dianhydride and 0.04mol of 3,3',4,4'-diphenyl ether dianhydride react in DMAc solvent at 0°C, the solid content of the obtained polyamic acid solution is 15wt%, and the intrinsic viscosity is 2.1 dl / g;

[0087] (2) Cast the solution prepared in step (1) into a film under the condition of 25° C., the carrier is a glass plate, and dry it in a drying oven at 60° C. for 6 hours;

[0088] (3) Put the film and carrier obtained in step (3) into the electric heating blower, heat up at 3°C / min, and keep warm at 135°C, 300°C, and 350°C for 2 hours each, and cool naturally after the program ends;

[0089] (4) Put the film and carrier through step (3) into boiling water for 10 minutes to remove the film;

[0090] (5) Put the film after step (4) into a drying oven, keep it at 200° C. for 10 min...

Embodiment 3

[0092] (1) According to the CTE of the matched Al metal substrate (shown in Table 4), take 0.03mol of 4,4'-diaminobenzanilide and 0.07mol of 4,4'-diaminodiphenyl ether and 0.1mol of pyromellitic dianhydride was reacted in a DMAc solvent at 0°C, and the obtained polyamic acid solution had a solid content of 15wt% and an intrinsic viscosity of 2.0dl / g;

[0093] (2) Cast the solution prepared in step (1) into a film under the condition of 25° C., the carrier is a glass plate, and dry it in a drying oven at 60° C. for 6 hours;

[0094] (3) Put the film and carrier obtained in step (2) into the electric heating blower, heat up at 3°C / min, and keep warm at 135°C, 300°C, and 350°C for 2 hours each, and cool naturally after the program ends;

[0095] (4) Put the film and carrier through step (3) into boiling water for 10 minutes to remove the film;

[0096] (5) Put the film after step (4) into a drying oven, keep it at 200° C. for 10 min to remove moisture to prepare the polyimide fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com