Metal-based composite material device based on gas-liquid phase change and preparation method of metal-based composite material device

A composite material and metal-based technology, which is applied in the direction of electrical components, electrical equipment structural parts, and modification using liquid cooling, etc., can solve the difficulty of integrating low-expansion heat source materials, excessive differences in thermal expansion coefficients, and insufficient miniaturization of devices, etc. problems, achieve the effects of reducing thermal mismatch rate, controllable thermal expansion, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In another technical solution of the present invention, a method for preparing a metal matrix composite device based on gas-liquid phase transition is provided, including the following steps:

[0053] (1) prepare respectively the upper shell and the lower shell that can form the metal tubular shell;

[0054] (2) Plating a thin metal layer on the inner wall of the upper shell and the lower shell;

[0055] (3) using a positioning mold to place the porous medium axially between the upper shell and the lower shell, and sintering to form a porous medium layer;

[0056] (4) modifying the porous medium layer so that its surface can adhere to a liquid working medium;

[0057] (5) The upper shell and the lower shell are sealed and packaged to form a metal tube shell, and at the same time, a liquid filling port and a heat source device are installed on one end of the metal tube shell to obtain a heat dissipation device.

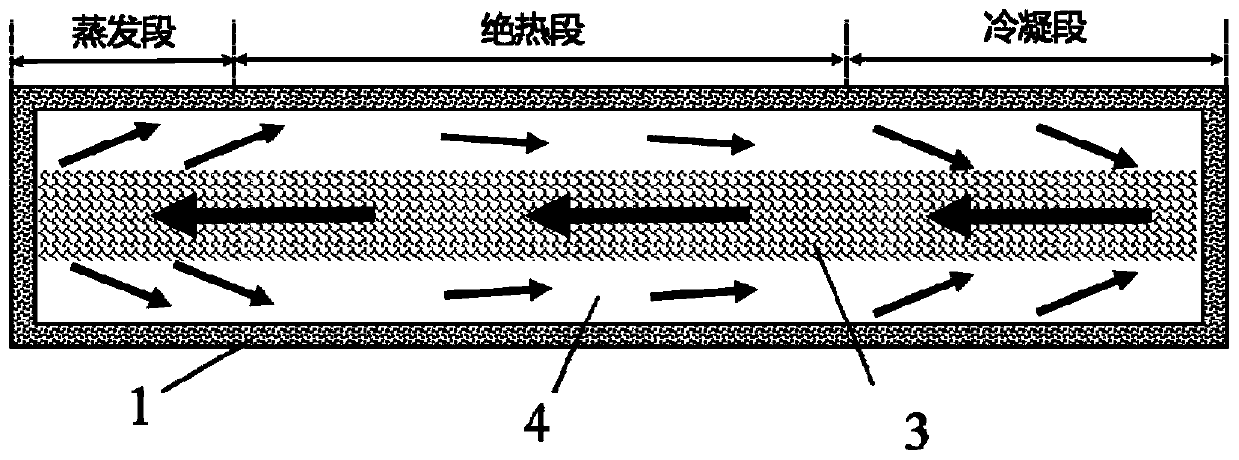

[0058] For the specific working principle of the metal m...

Embodiment 1

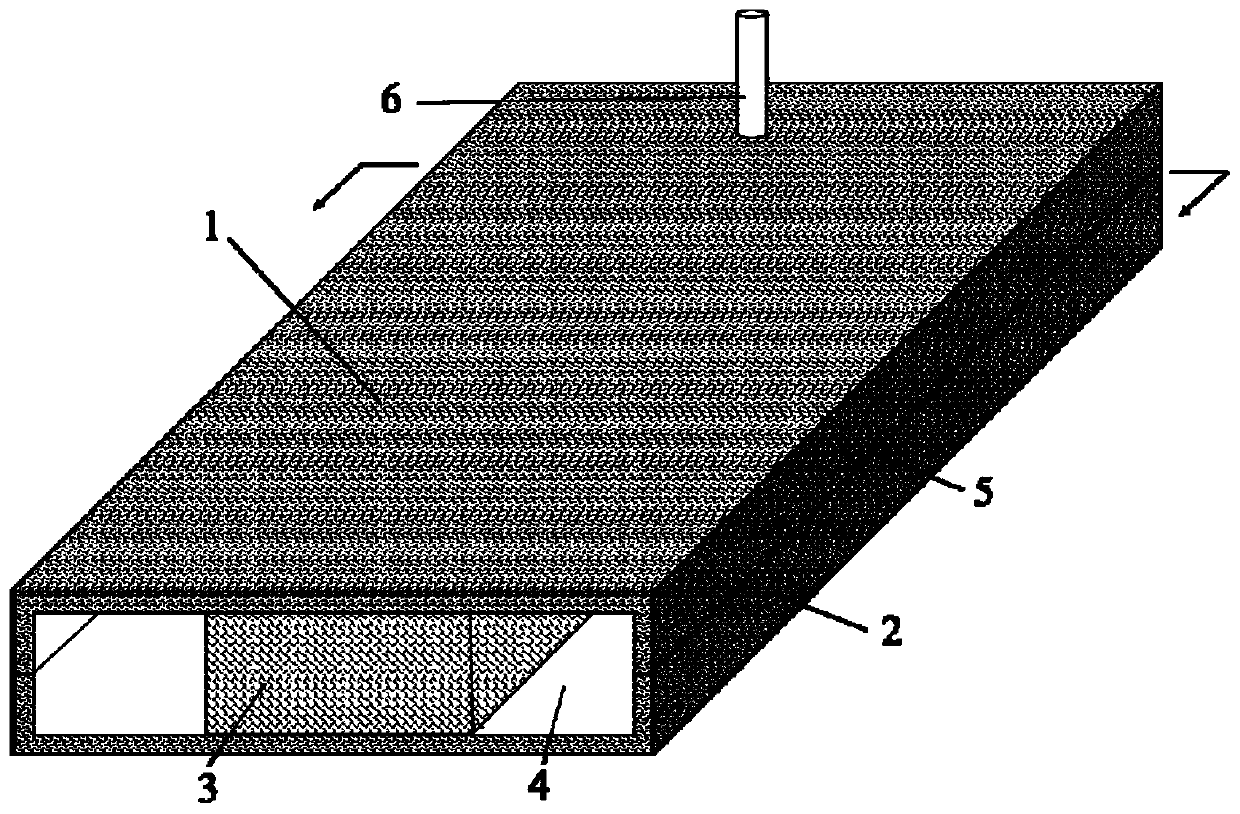

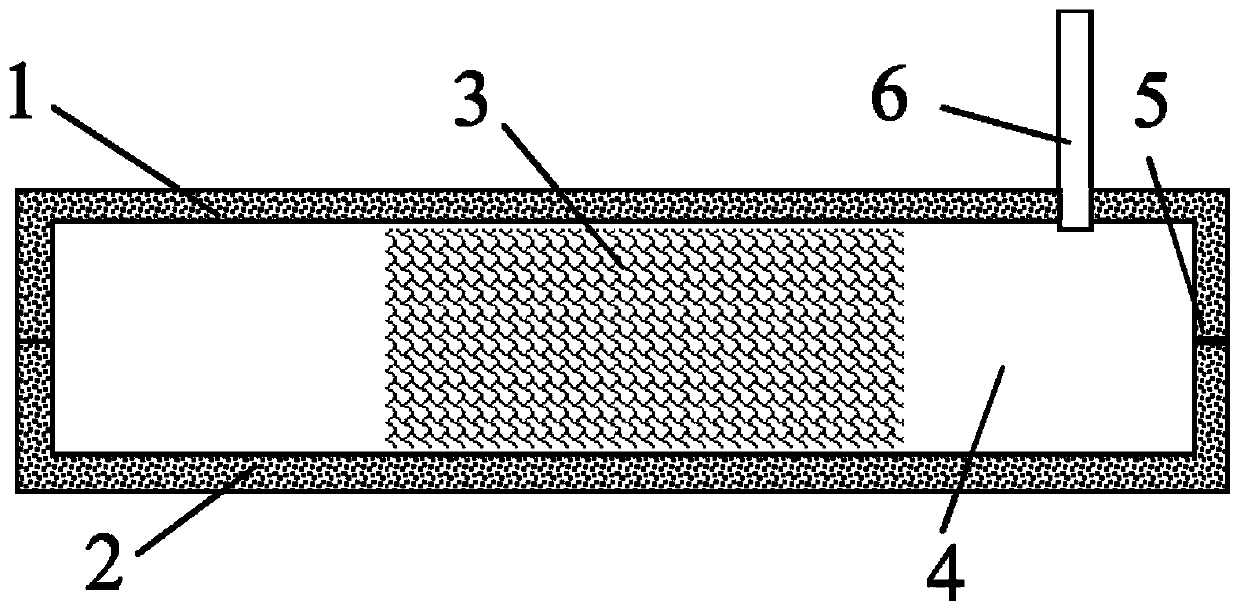

[0062] A metal matrix composite device based on gas-liquid phase change heat transfer, its structure please refer to Figure 1-Figure 3 , Figure 5 etc., its preparation method is as follows:

[0063] Step 1, shell forming: the upper shell and the lower shell are prepared on the metal matrix composite plate (WCu20) by machining.

[0064] Step 2, cleaning the surface of the composite material: firstly remove impurities such as organic matter on the surface of the metal matrix composite material shell; then use cathodic degreasing to further remove the grease on the surface; then remove the tungsten oxide on the surface, and then use dilute sulfuric acid to remove the surface Copper oxide; Finally, rinse the surface with deionized water two to three times to remove the residual dilute sulfuric acid solution on the surface and dry it.

[0065] Step 3, coating the surface of the composite material with a metal layer: using a chemical or physical method to coat a thin metal layer...

Embodiment 2

[0077] The metal matrix composite material device based on gas-liquid phase change heat transfer in this embodiment has the characteristics of controllable thermal expansion rate from the metal matrix composite material, and the metal matrix composite material plate with controllable expansion rate is processed into different lengths, widths, The shell of thickness, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com